Method for drying grain and grain drier

A drying method and dryer technology, which are applied in dryers for static materials, drying solid materials, local stirring dryers, etc., can solve the problems of leaking hot air and cumbersome operations, and achieve the effect of improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

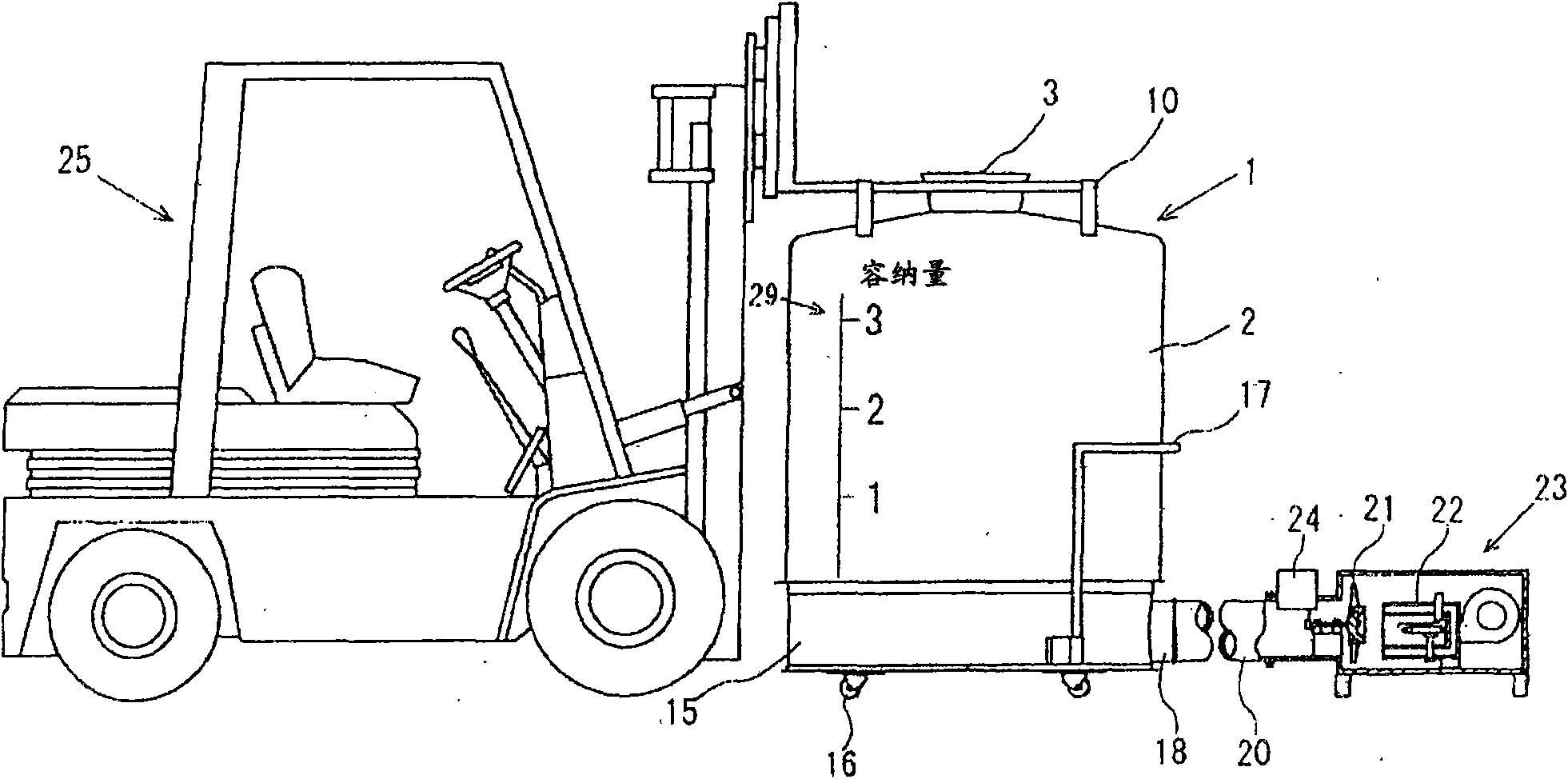

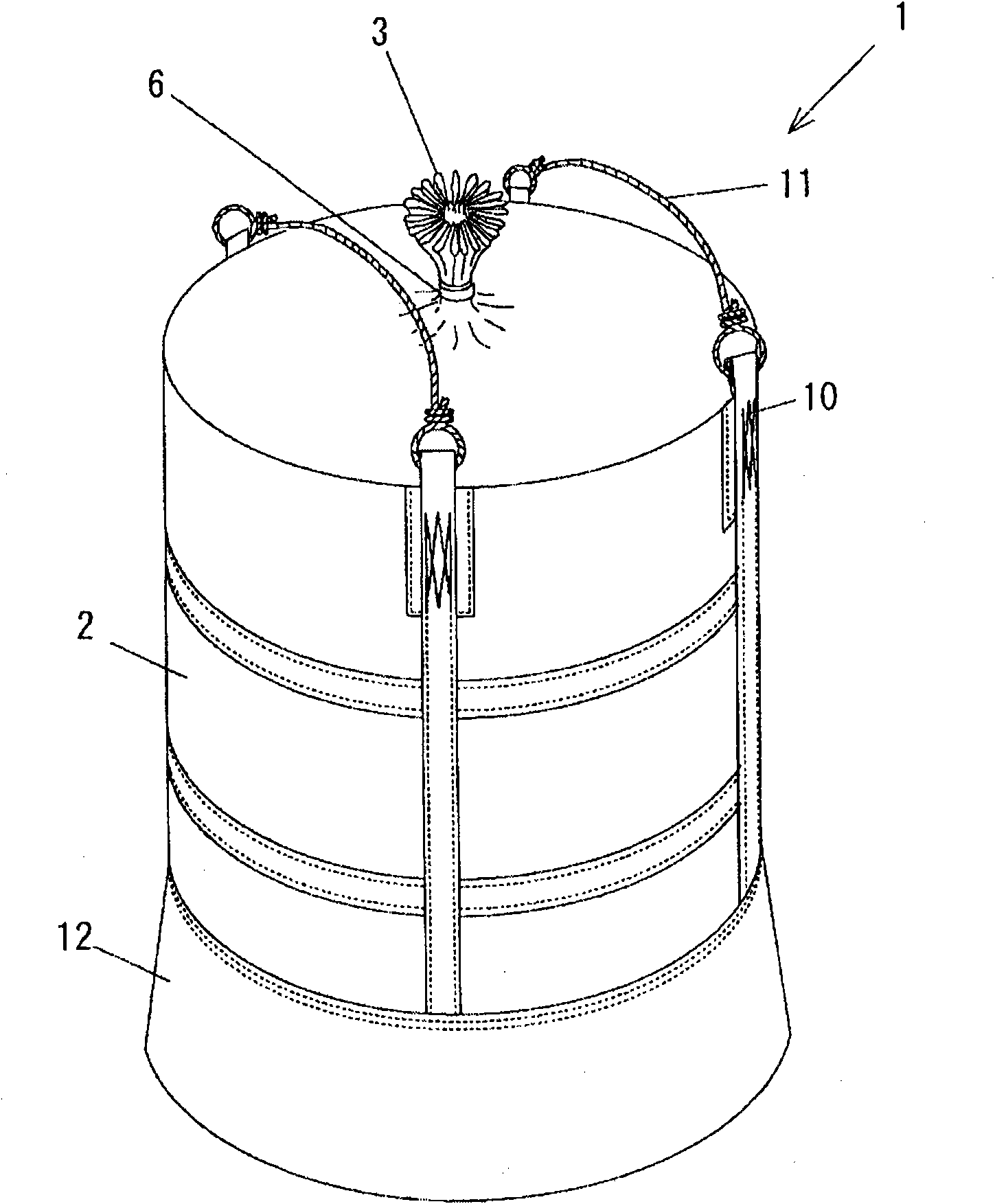

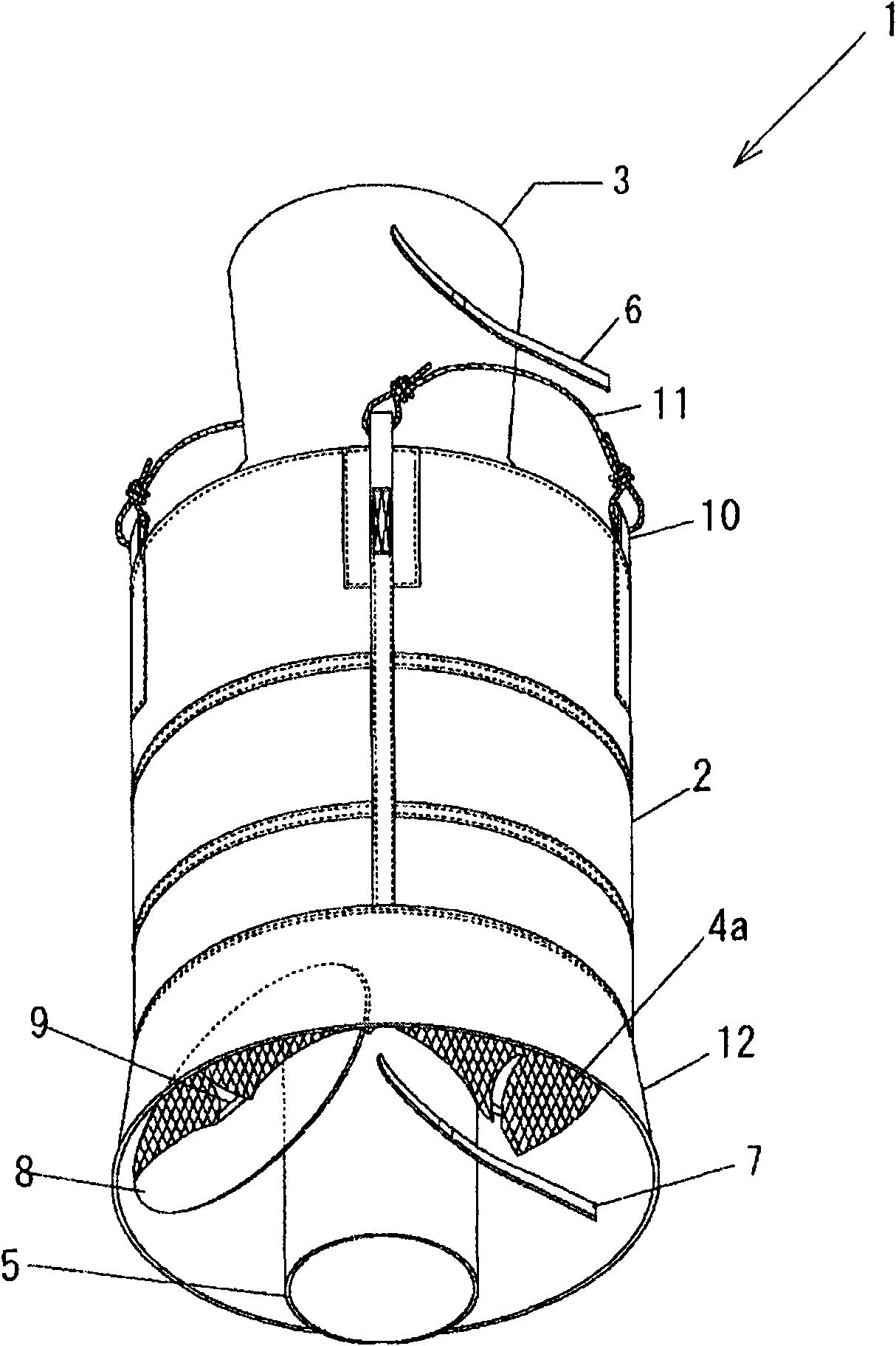

[0030] figure 1 It is a front view which shows the state which lifted the flexible container 1 which accommodated the paddy by the forklift 25 etc., and placed on the cylindrical drying casing 15 of the ventilation dryer. figure 2 It is a perspective view for showing the detailed structure of the flexible container 1 seen from the inlet side. image 3 It is a perspective view for showing the detailed structure of the flexible container 1 seen from the outlet side. Figure 4 It is a bottom view showing the bottom surface of the flexible container 1 .

[0031] Such as Figure 1 to Figure 4 As shown, the flexible container 1 is formed of polyvinyl chloride, polypropylene, etc., and mainly includes: a roughly cylindrical shell part 2 with a height of about 1.25m and a diameter of about 1.3m; The input port 3; the bottom surface 4 formed on the air-permeable net 4 ( Figure 4 ); and the central opening of the bottom surface 4, and the cylindrical discharge port portion 5 is co...

Embodiment 2

[0050] Figure 7 It is the second embodiment, which is a structure capable of fastening the skirt 12 of the flexible container 1 . Other structures are the same as in Embodiment 1.

[0051] Such as Figure 7 Shown in (a), a small channel-shaped rope-threading portion 13 ( Figure 9 ), and pass through the binding rope 14. By tightening the binding cord 14, the area of the opening 28 of the skirt 12 can be reduced. And, if Figure 7 Shown in (b), tighten the binding cord 14 and reduce the area of the opening 28 of the skirt portion 12, and place it on the drying housing 15 in this state ( Figure 8 ).

[0052] Figure 9 yes Figure 8 The enlarged sectional view of the main part of the part surrounded by the symbol A is placed on the drying shell 15 after reducing the area of the opening 28 of the skirt 12, and then the skirt 12 bulges slightly toward the outer direction of the side wall 15a of the drying shell 15. , and the lower periphery of the skirt 12 is sand...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com