Assembly, in particular internal combustion engine or compressor

A technology of compressors and internal combustion engines, which is applied in the direction of machines/engines, mechanical equipment, engine components, etc., can solve problems affecting the quietness of component operation, and achieve the effect of reducing quantity and economical production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

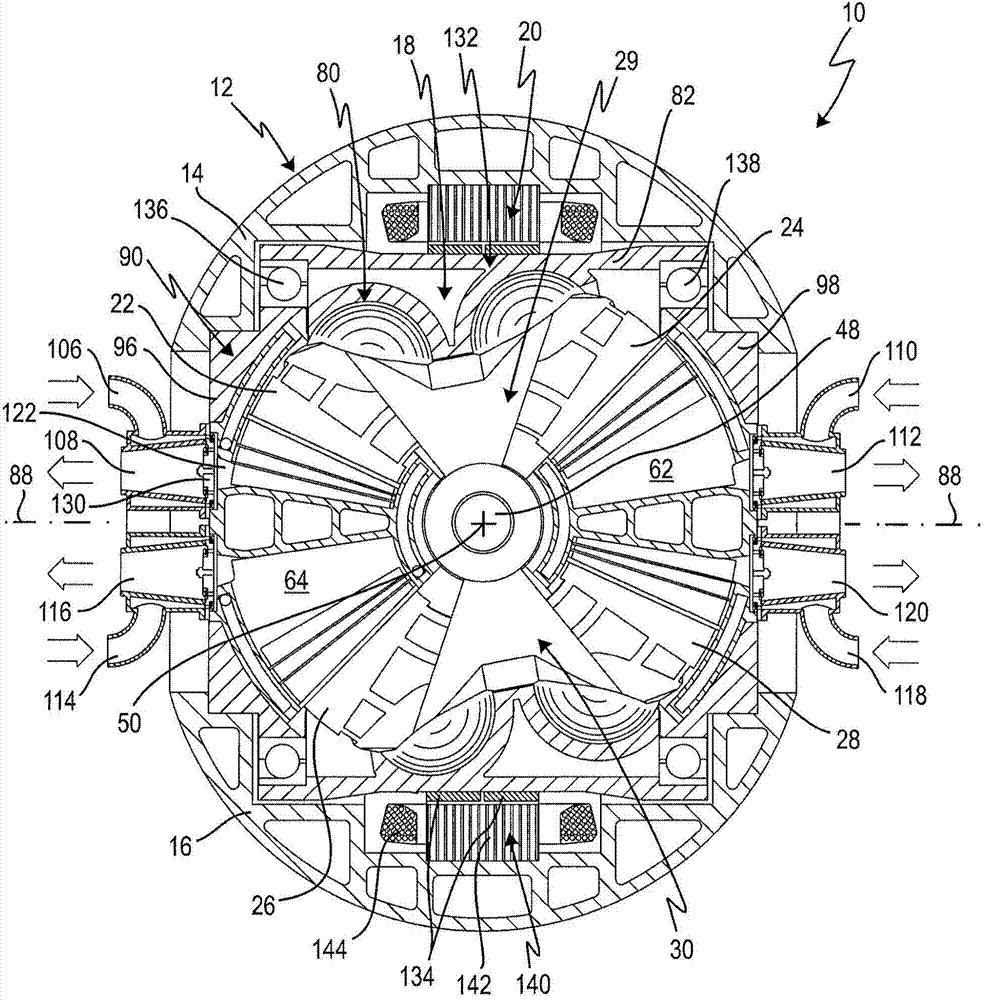

[0059] figure 1 Components are shown with the general reference numeral 10 . In the illustrated embodiment example, the assembly 10 is formed as a compressor with an integral electric motor component. However, with minor modifications, the assembly 10 can also be used as an internal combustion engine with an integrated electric motor component. However, use as a compressor is the preferred use.

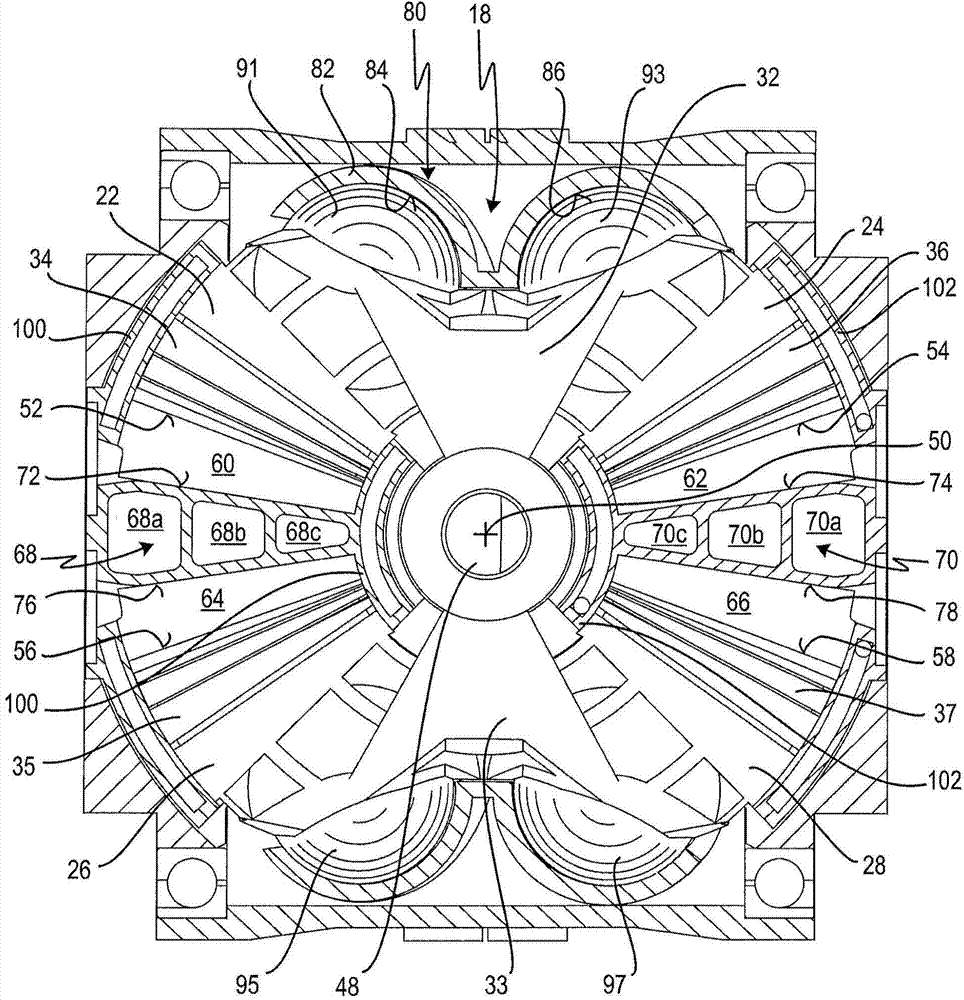

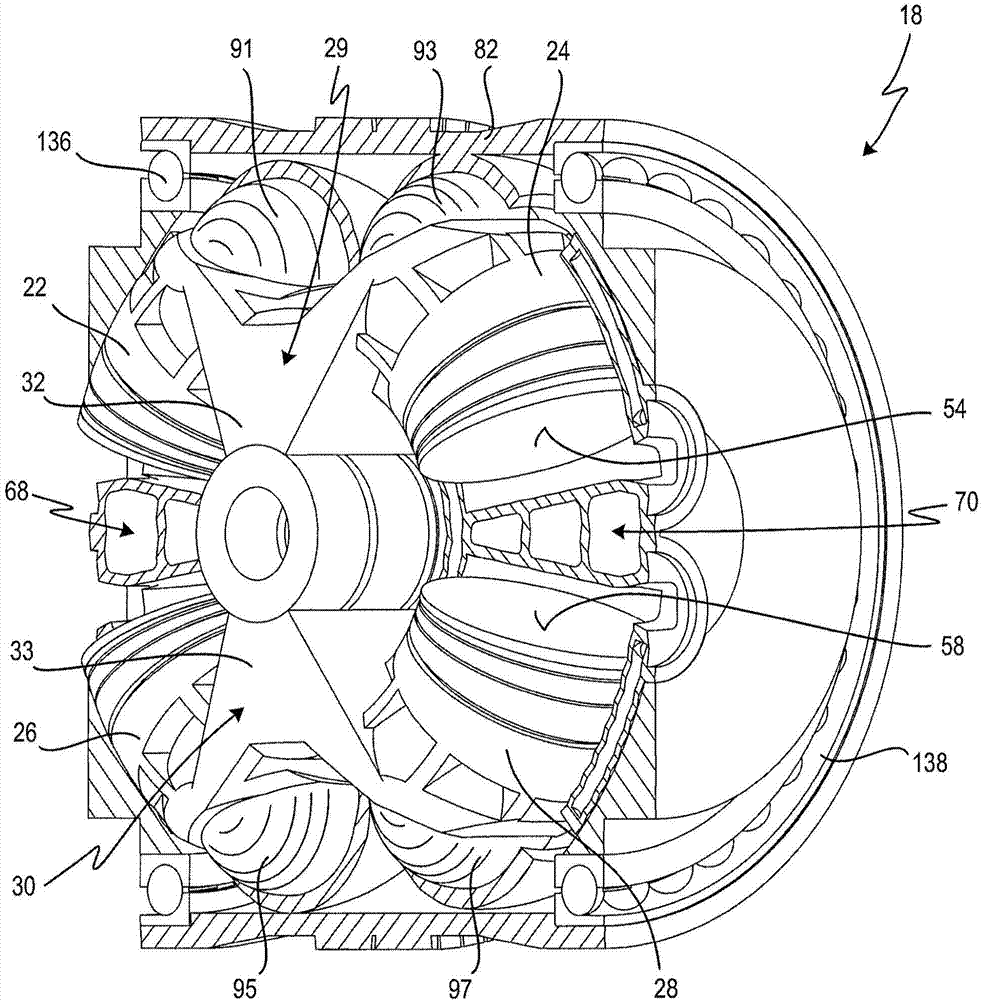

[0060] exist Figures 2 to 9 Additional details of assembly 10 are shown in . Figure 10 A slightly modified embodiment example of assembly 10 is shown.

[0061] refer to figure 1, the assembly 10 has a housing 12 which is essentially formed from two half-shells 14 and 16 . The two half-shells 14, 16 are fastened together via a number of bolts not shown.

[0062] Arranged within the housing 12 are a piston engine component 18 and an electric motor component 20 . First also refer to Figures 2 to 9 Piston engine component 18 is described in more detail.

[0063] The piston en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com