Polygonal driving means with inbuilt collar

A driving component, polygonal technology, applied in the direction of connecting components, threaded fasteners, screws, etc., can solve the problem that it is impossible to forge angular shapes, etc., to achieve easy identification and improve the effect of heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

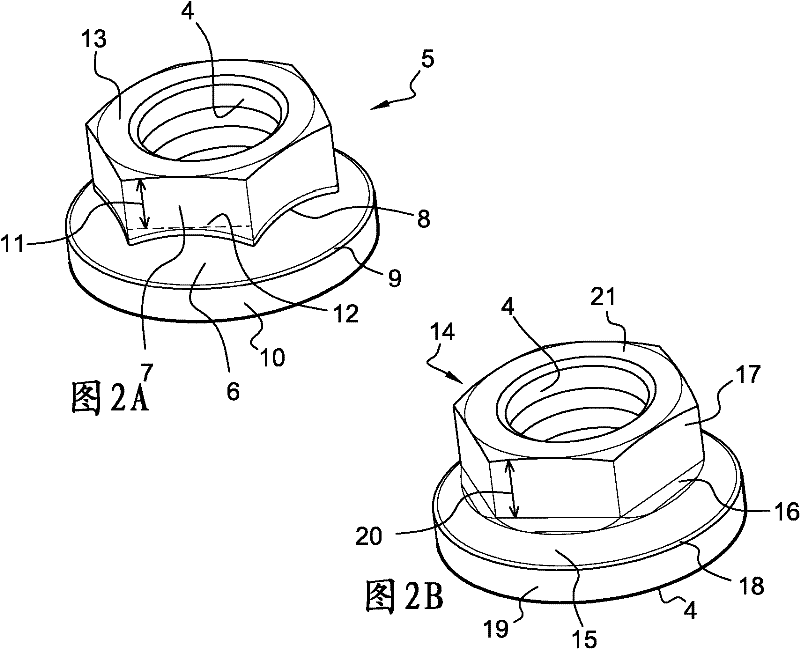

[0062] Figure 3A An oblique perspective view of a first example of a nut with a drive part 23 with a frusto-conical flange 6 according to the invention is schematically shown. In an example, the drive part 23 shown on the lower view and its variants are obtained by forging using a die. In a variant, the drive part can also be obtained by another manufacturing method, such as machining, moulding, injection molding, calcination, so that whatever the manufacturing method is used, it has the same driving part in use. The drive part 23 comprises a polygonal, here hexagonal, shank 7 and a frustoconical flange 6 . According to the invention, the flange 6 is provided with a depressed side surface 24 . In the example of FIG. 3 , the side surface 24 is flat. According to the invention, depression means that a surface portion is inclined inwardly with respect to the frusto-conical curved surface. The circular base 18 of the cone of the flange 6 extends to a cylinder 19 . The drive ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com