Line climbing robot

A technology of robot and main frame, applied in the direction of lifting device, hoisting device, etc., can solve problems such as inability to climb to a sufficient height and limitation of climbing distance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

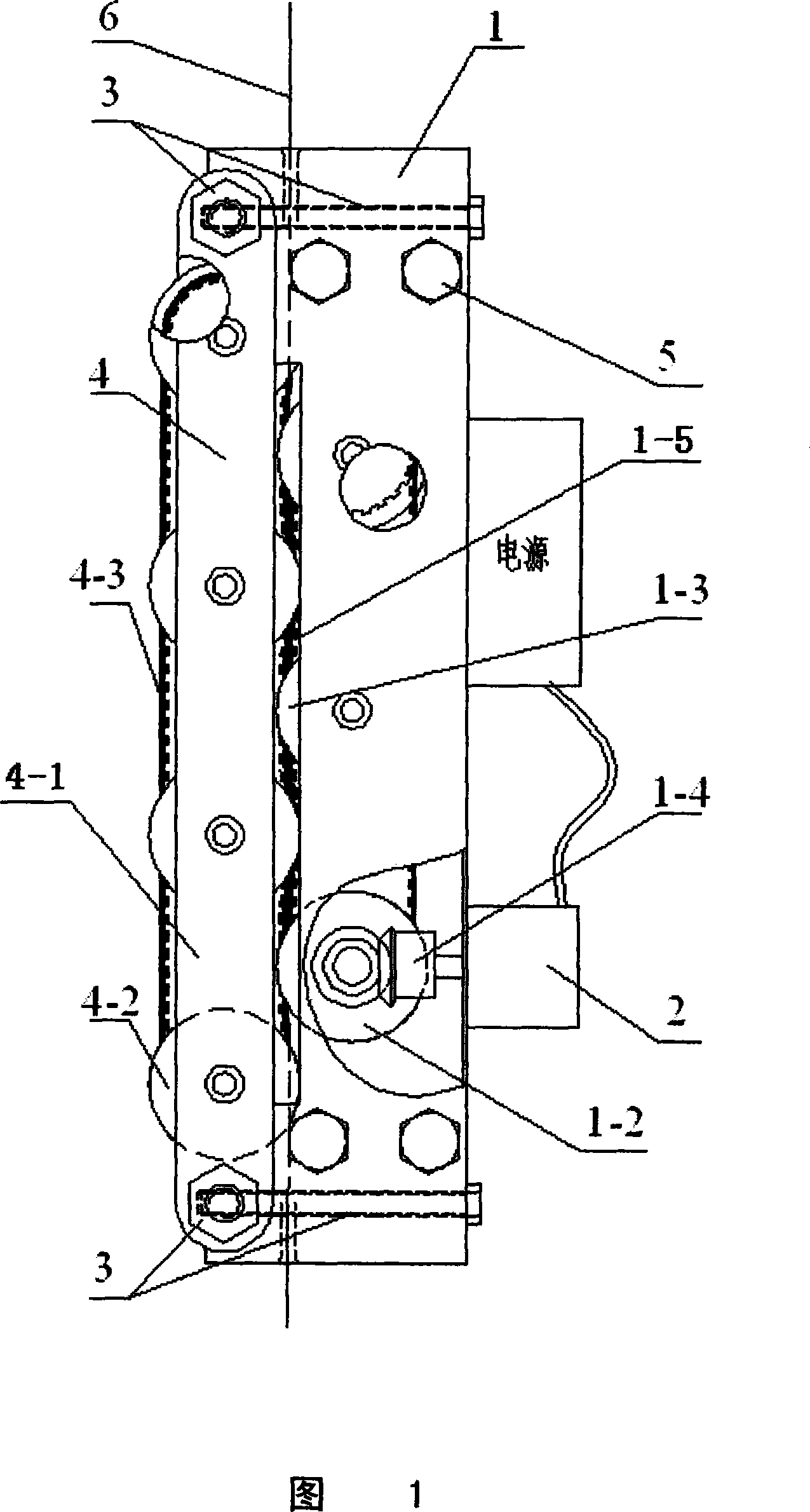

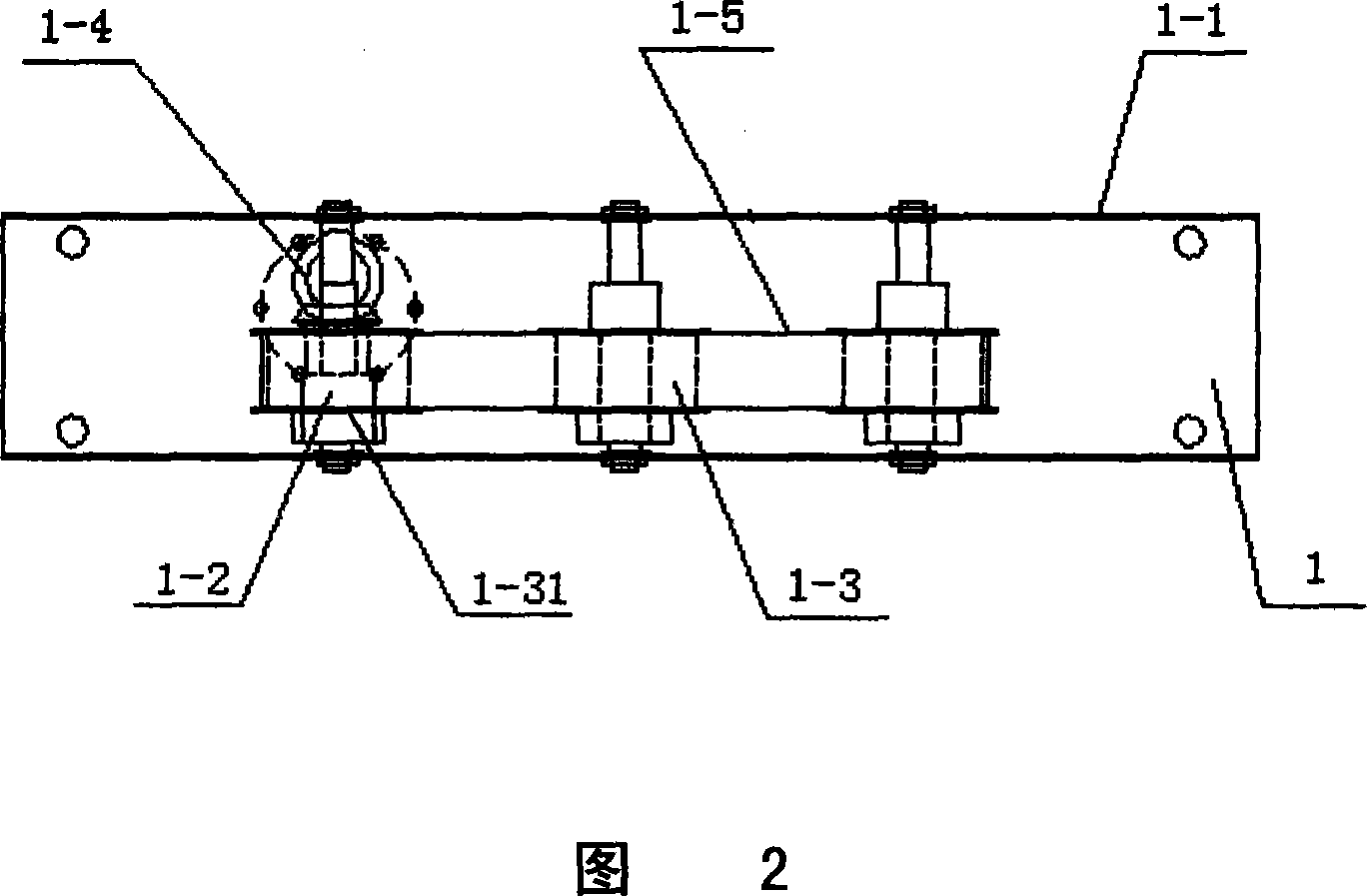

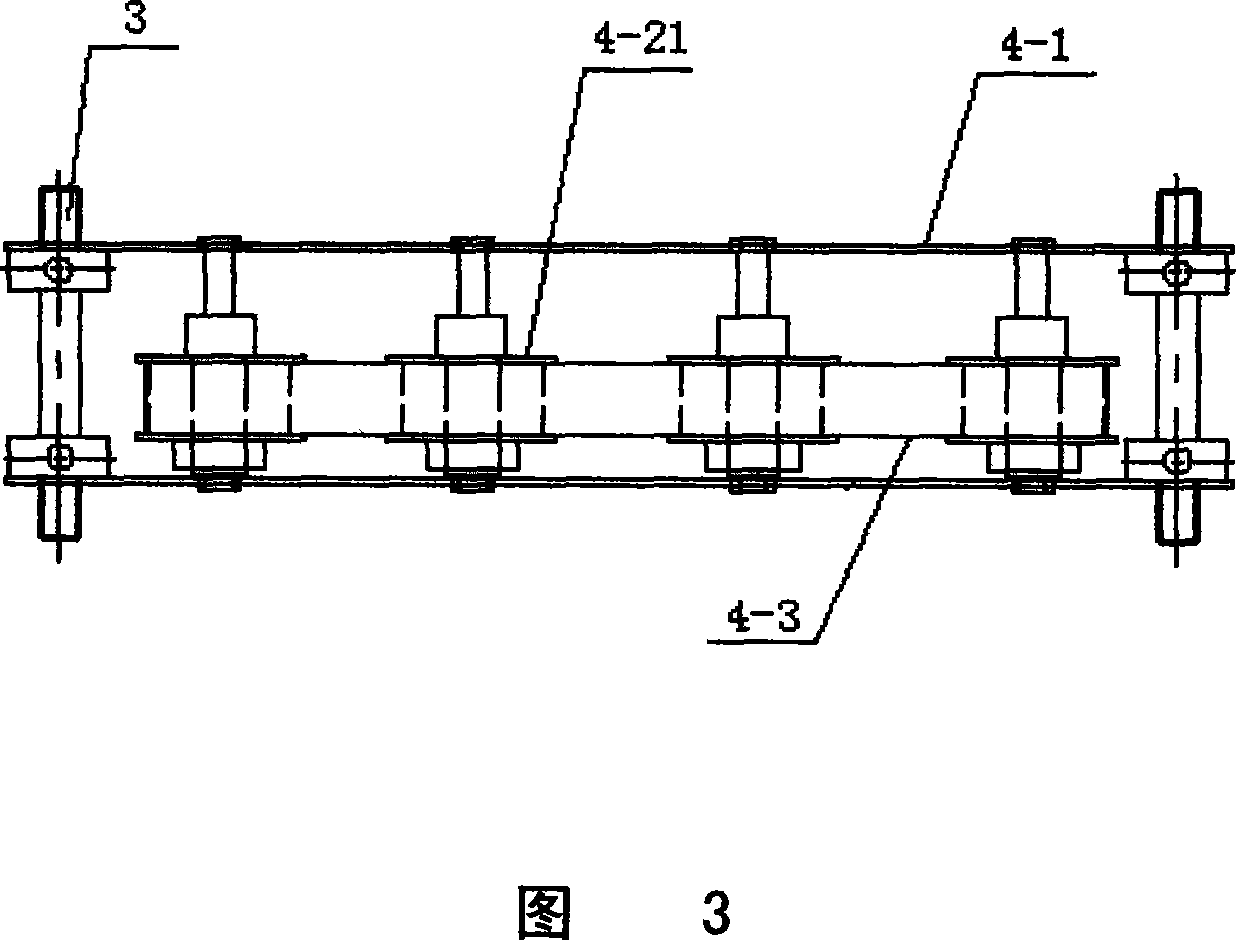

[0017] This continuous climbing robot as shown in the figure is a creative improvement to existing climbing robots along straight rods and ropes, and is especially suitable for climbing when using thin and soft ropes and steel wires as carriers. Its specific structure is as follows:

[0018] This climbing robot consists of a climbing device and a driving motor 2, and is characterized in that: the climbing device includes a main climbing transmission mechanism 1 driven by a driving motor, a transmission wheel, and a transmission wheel belt. 1. The climbing auxiliary transmission mechanism 4 composed of transmission wheels, the two ends of the climbing main transmission mechanism 1 and the climbing auxiliary transmission mechanism 4 are connected into one body by the clamping assembly 3 arranged at the two ends to form the main body of the climbing combination , and the transmission wheels in the climbing main transmission mechanism 1 and the transmission wheels in the climbing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com