High thermal load large power semiconductor laser

A technology of semiconductors and lasers, which is applied in semiconductor lasers, lasers, laser components, etc., can solve problems such as poor stability, decreased optical coupling efficiency, and low optical power, and achieve reliability, good heat dissipation, and stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

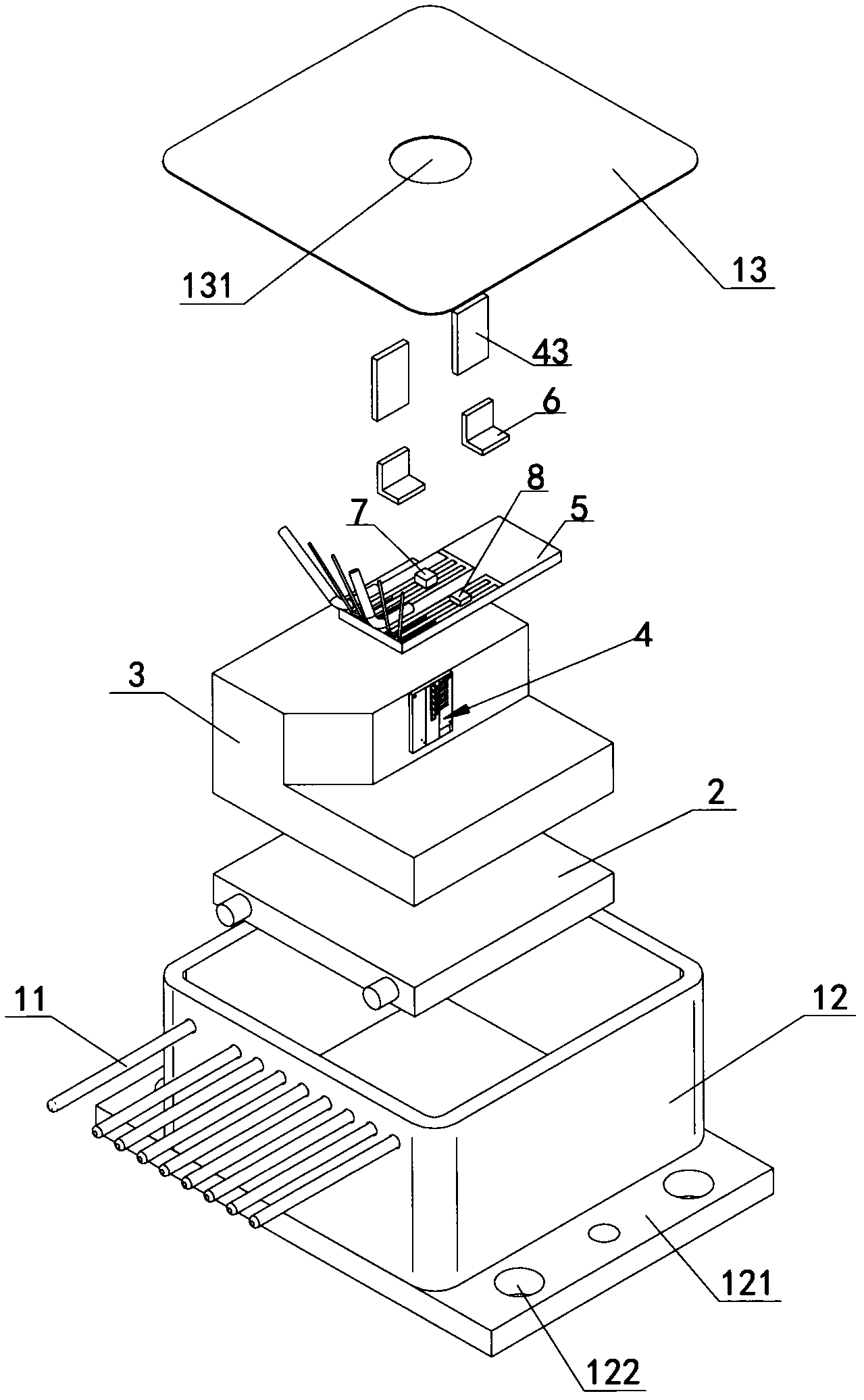

[0026] The preferred embodiment of the present invention will be described in detail below in conjunction with accompanying drawing:

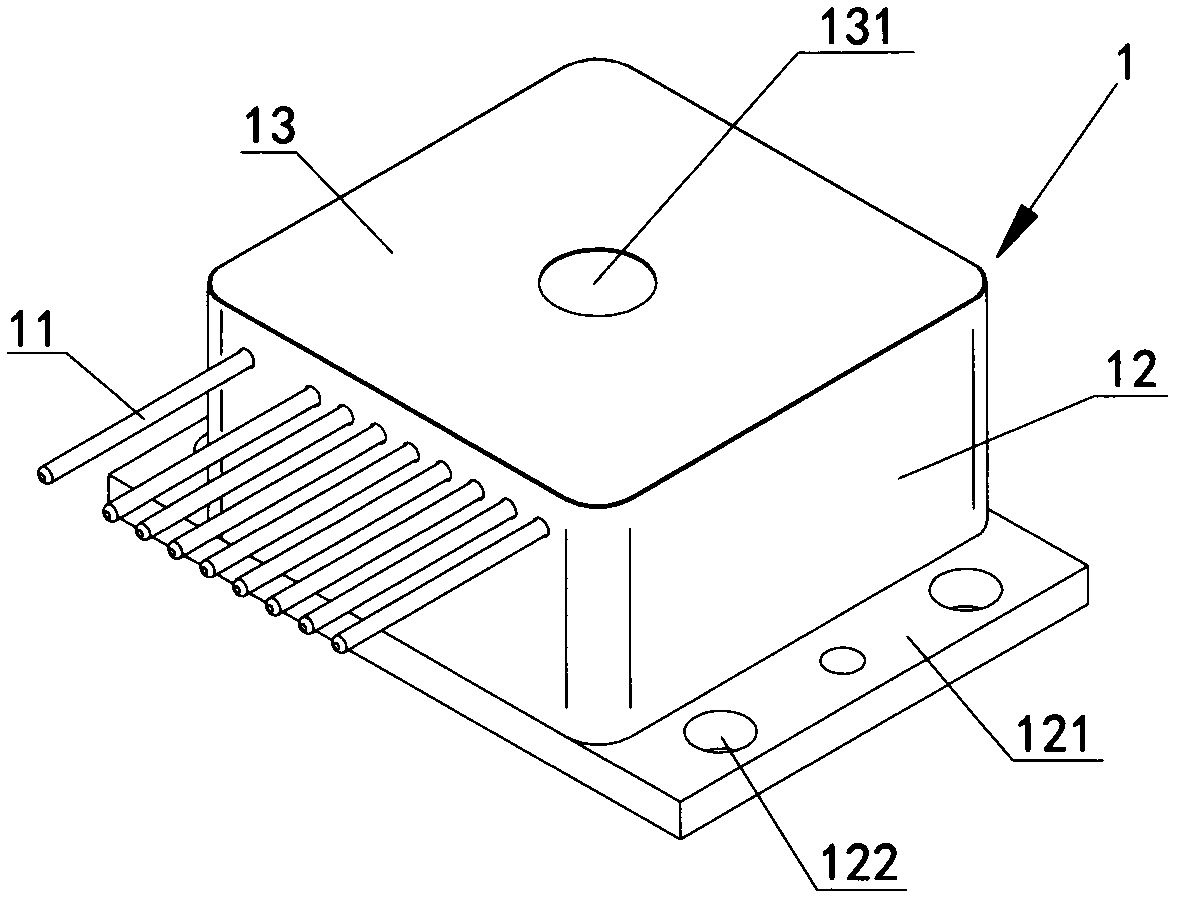

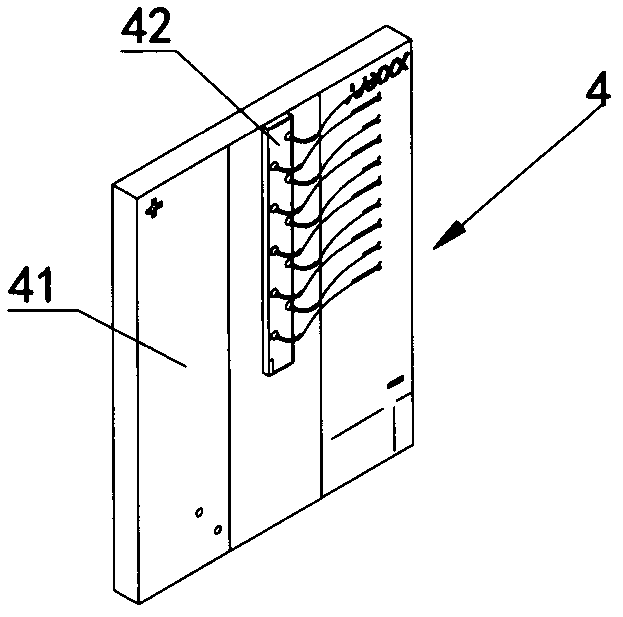

[0027] Such as figure 1 , image 3 and Figure 4 The shown semiconductor laser comprises a housing 1, a TEC refrigerator 2 arranged in the housing 1, a heat sink 3 fixed on the TEC refrigerator 2, a semiconductor laser chip assembly 4 pasted on the heat sink 3, and a For the drive circuit board 5 that realizes electro-optical conversion, the specific structural features of each part will be described below:

[0028] The housing 1 is mainly composed of a housing base 12 and a housing cover 13 closely fitted to the upper edge of the housing base 12 . In this embodiment, the housing 1 is in the shape of a cuboid as a whole, and a connecting wing 121 is extended from the bottom of the housing base 12, and a connecting hole 122 is provided on the connecting wing 121, through which the semiconductor laser is connected to the equipment to be insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com