Modularized 3D building printer

A modular and printer technology, applied in the construction, building structure, construction material processing and other directions, can solve the problems of hindering the development of 3D architectural printing, unable to print on site, etc., to improve the processing efficiency and improve the walking speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with accompanying drawing.

[0028] It should be noted that the relative arrangement, numerical values, etc. of components set forth in the present embodiment are not limited to the scope of the present invention unless specifically stated otherwise.

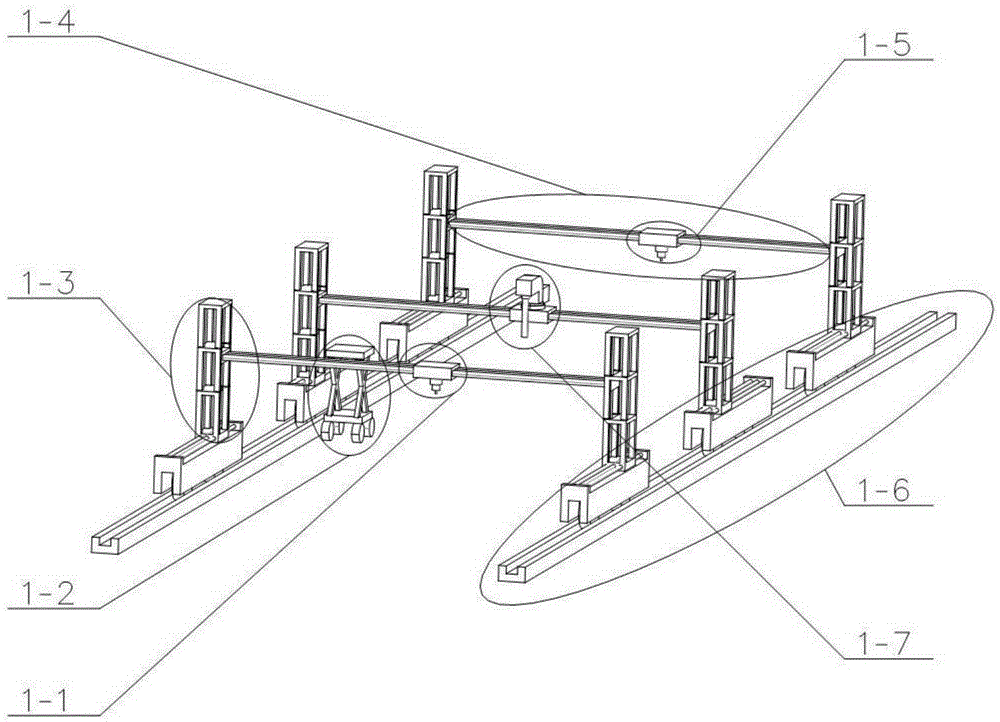

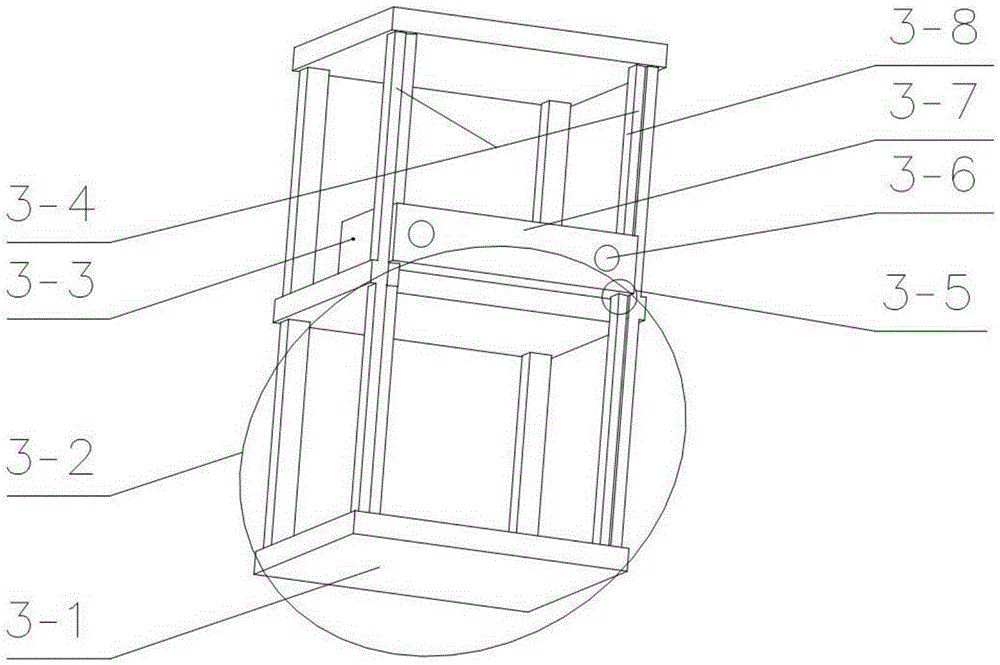

[0029] This article describes a single splicable and extended double-layer walking mechanism 1-6, two-layer splicable and elevated vertical lifting mechanisms 1-3, multiple splicable and extended double-layer walking mechanisms 1-6 and multi-layer splicable lifting The principle of the high vertical lifting mechanism 1-3 is the same as that of the single splicable and extended double-layer walking mechanism 1-6 and the two-layer vertical lifting mechanism 1-3 that can be spliced and raised; Mechanisms 1-6 and two-layer vertical lifting mechanisms 1-3 that can be spliced and raised are described in detail as examples.

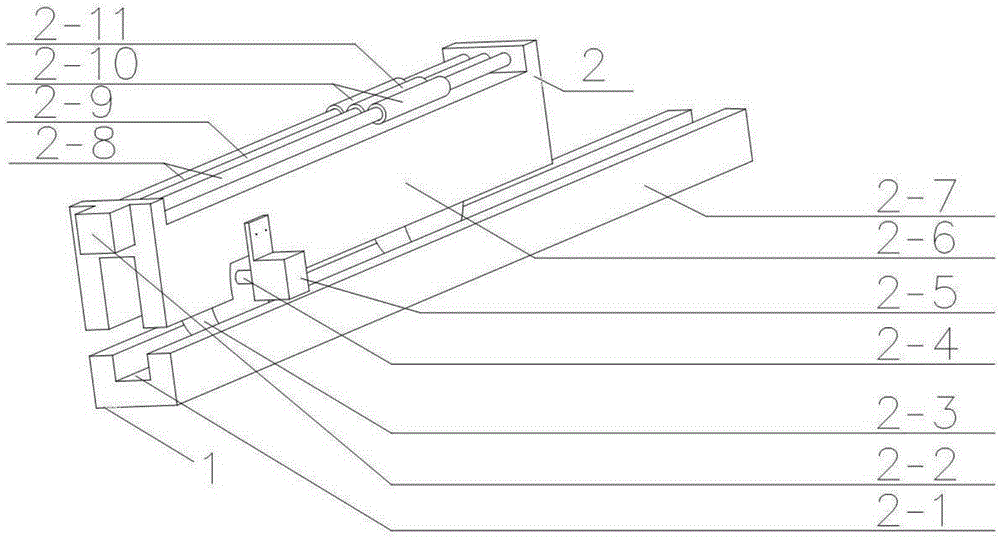

[0030] Such as figure 1 Shown...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com