Gantry wrapping machine with jacking platform

A technology for lifting platforms and wrapping machines, which is applied in the field of wrapping machines and gantry wrapping machines, can solve the problems of low automation, low efficiency, and the inability to adjust the height of the goods to be packed, and achieve convenient operation, reliable performance, improved winding efficiency and Effect of Winding Quality Stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

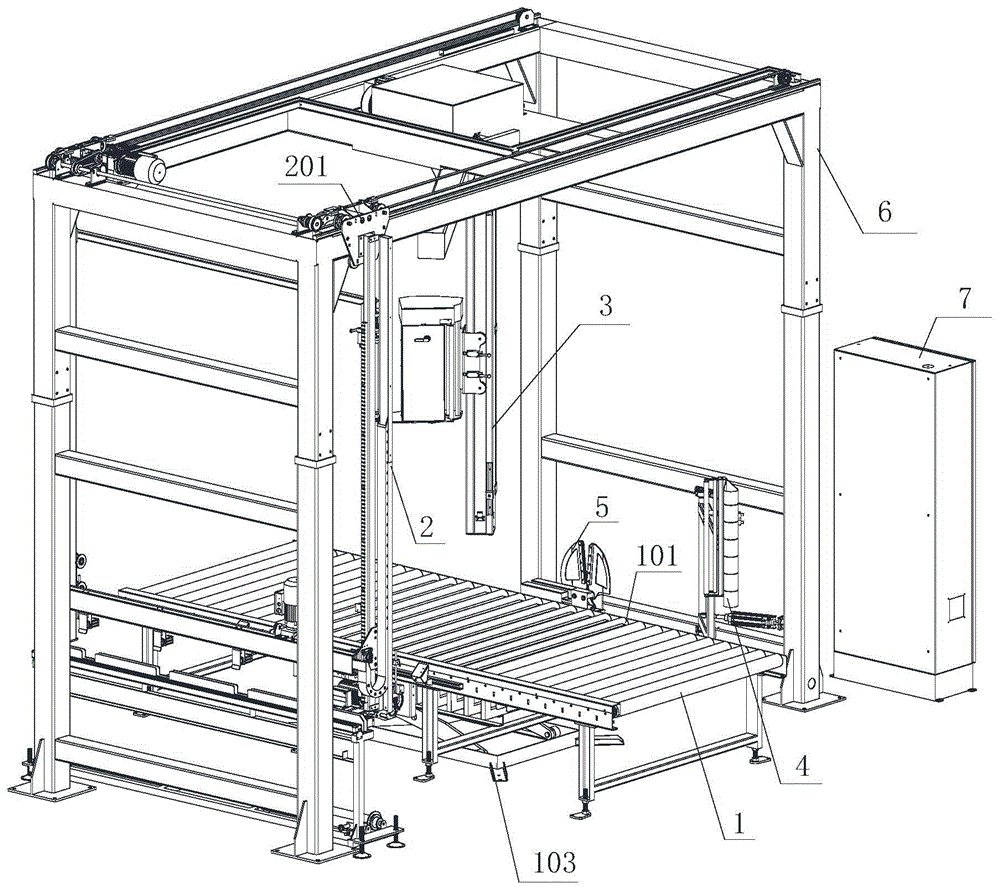

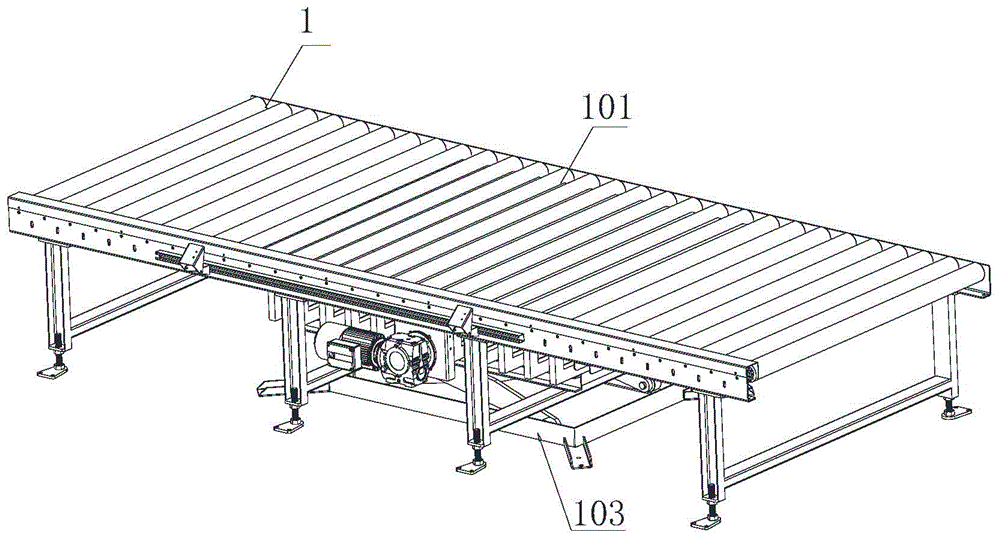

[0028] Such as figure 1 As shown, a gantry wrapping machine with a jacking platform includes: a gantry 6 positioned on a cargo conveying line 1, a roofing device 2 and a rotary arm winding device 3 positioned on the gantry 6, the cargo conveying line 1 is provided with a jacking platform.

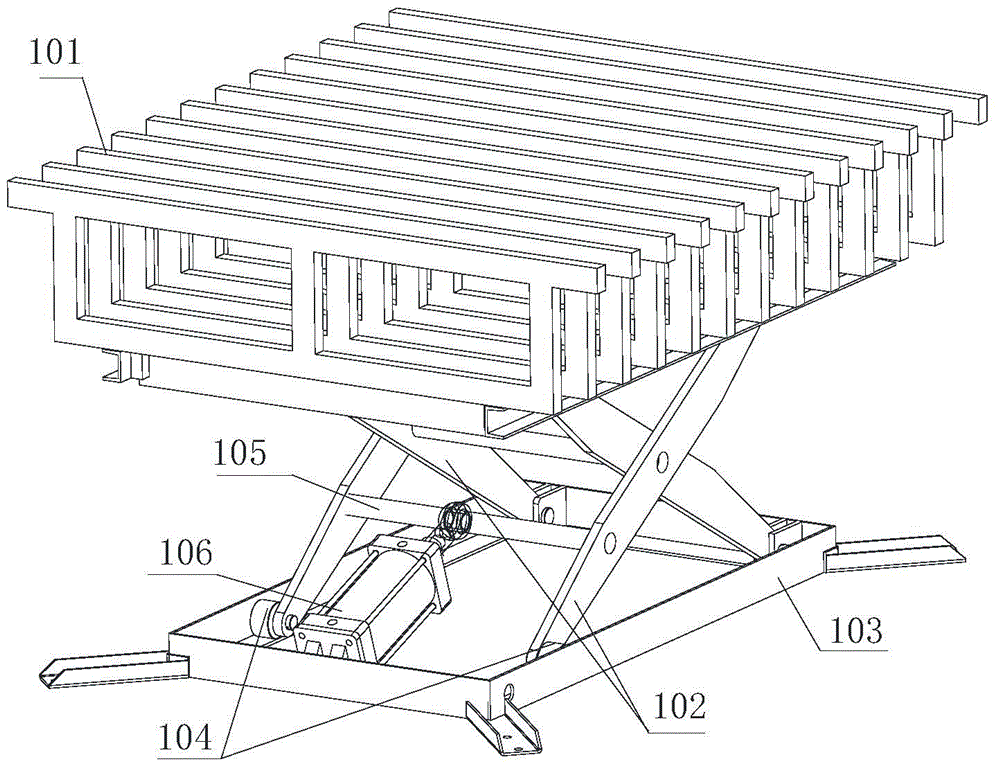

[0029] Such as Figure 2-4 As shown, the lifting platform includes: a grid platform 101 that can pass through the gap between the rollers arranged in parallel on the cargo conveying line 1, and the angle at which the upper end is connected to the bottom of the grid platform 101 through rotating connectors is adjustable. The X-shaped support 102; the bottom end of the X-shaped support 102 is connected with the base 103 by a rotating connector, and the other side is connected with the sliding wheel 104 sliding in the horizontal track on the base 103; and the X-shaped support 102 One side that is connected with sliding wheel 104 is connected with a transverse bar 105, and this transverse bar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com