Yarn winding device and textile machine

A winding device and yarn technology, applied in the field of fiber machinery, can solve the problem that the yarn feeding part and bobbin supplying part cannot be driven independently, and achieve the effect of easy maintenance and simple maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Next, embodiments of the present invention will be described. This embodiment is an example in which the present invention is applied to an automatic winder that rewinds a yarn unwound from a bobbin onto a winding bobbin to form a winding package.

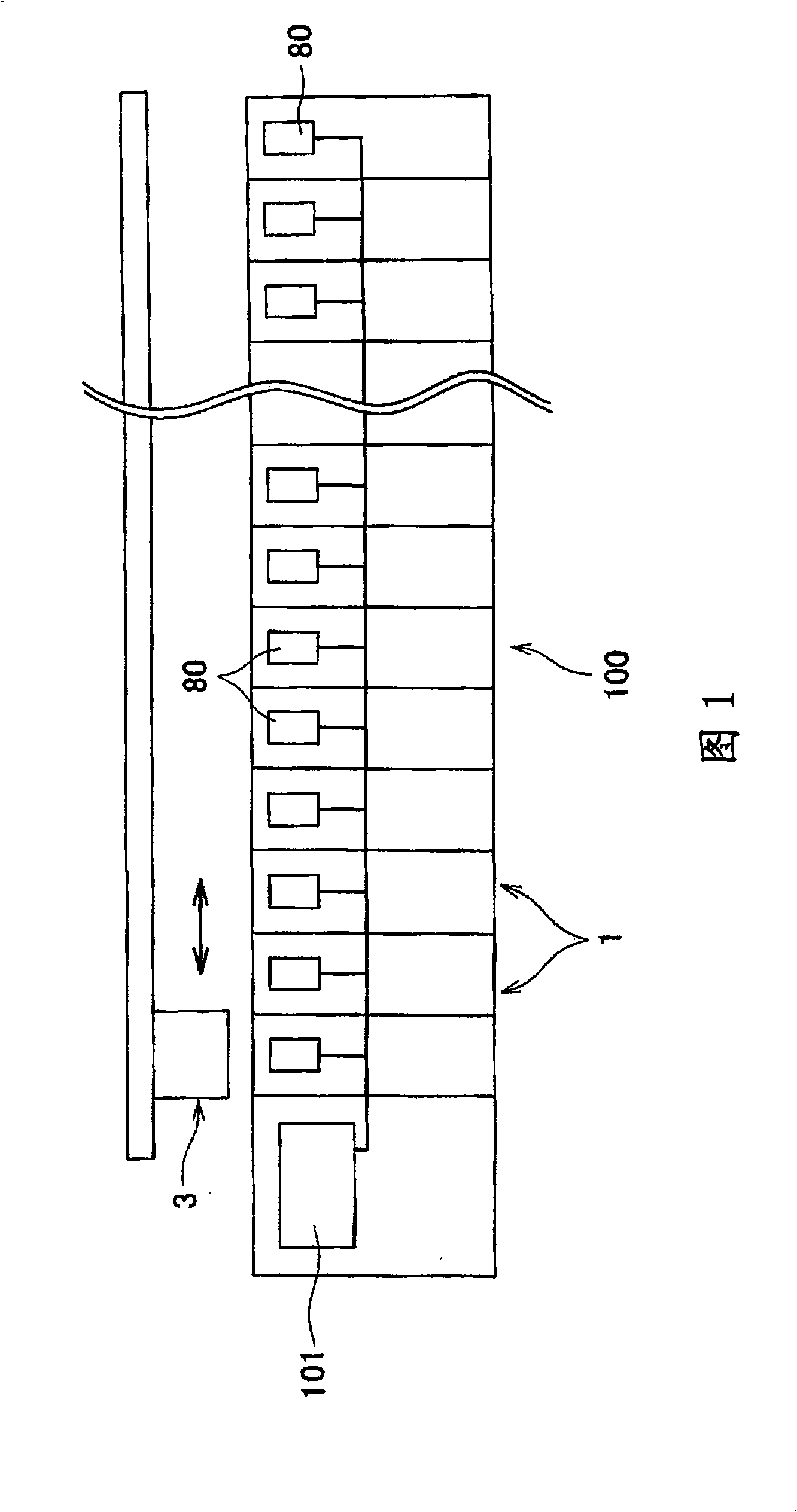

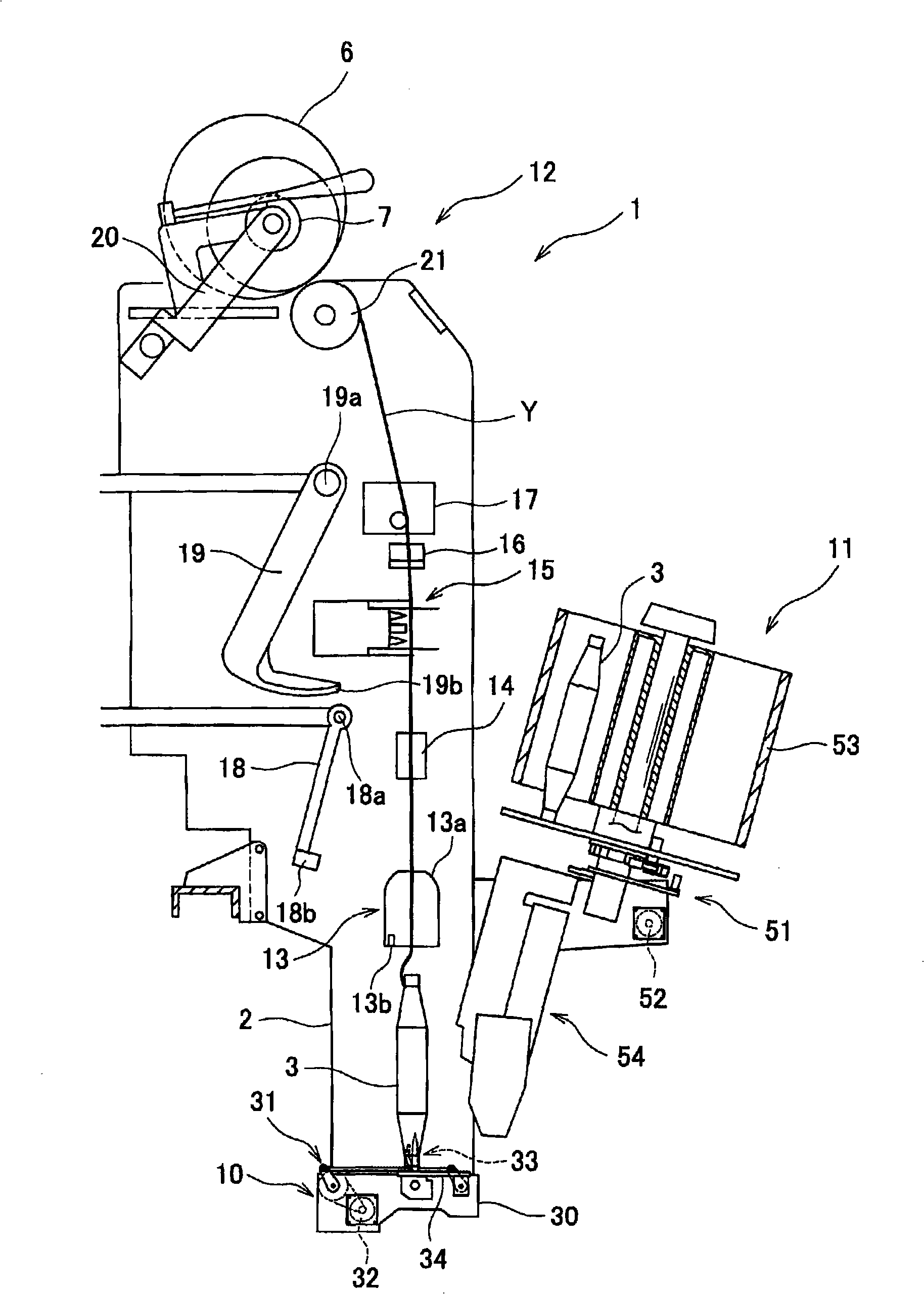

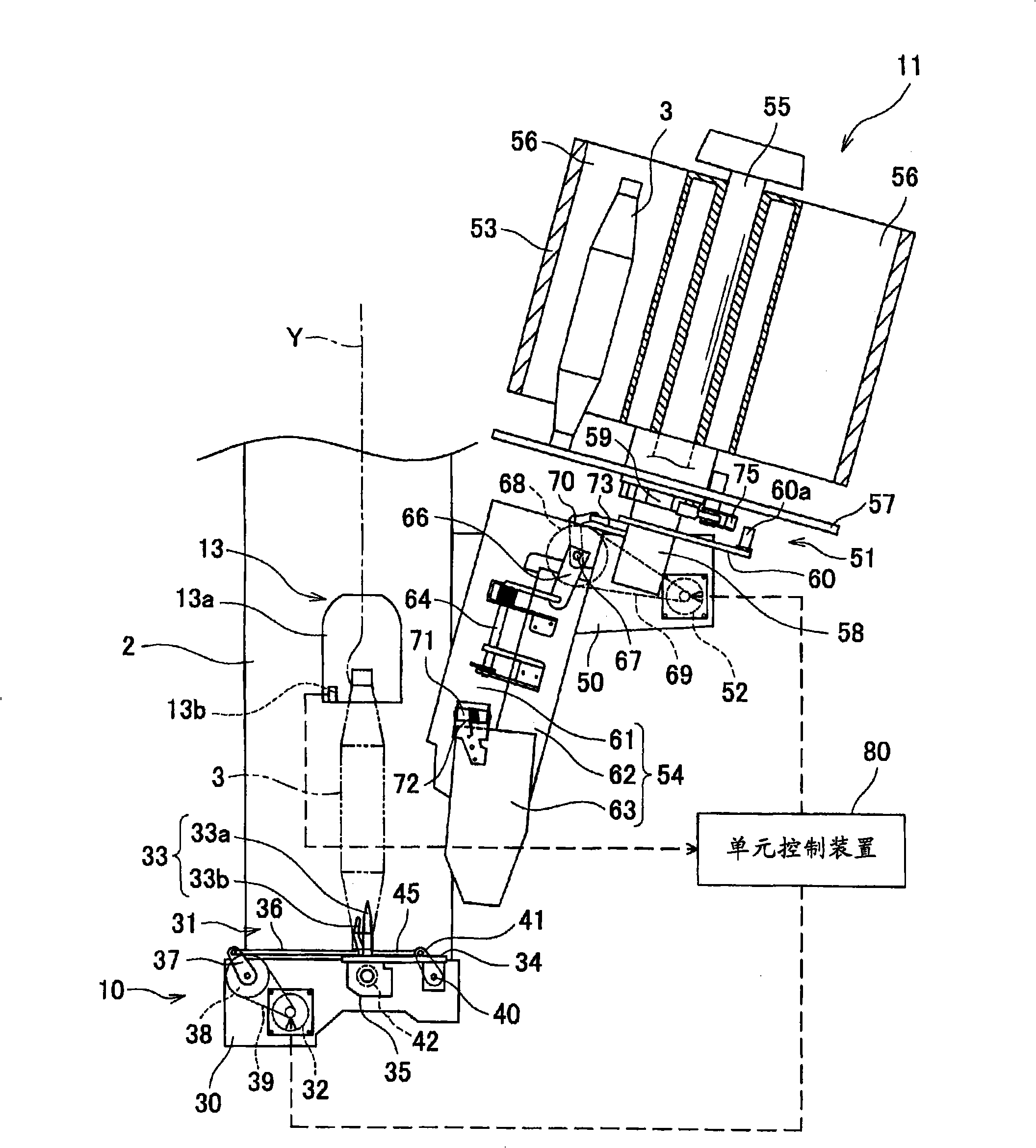

[0038] Fig. 1 is a schematic structural diagram of an automatic winder, figure 2 is a schematic side view of a winding unit of an automatic winder, image 3 Yes figure 2 An enlarged view of the substructure of the winding unit. Figure 1 andfigure 2 Shown, automatic winder 100 (fiber machine) has along one direction ( figure 2 The multi-spindle winding unit 1 (yarn winding device) arranged in a row in the direction perpendicular to the paper surface). In addition, the automatic winder 100 has a doffing device 3 capable of reciprocating along the direction in which the winding units 1 are arranged. The doffing device 3 unloads a fully wound winding package 6 formed by a plurality of winding units 1 from the winding unit 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com