Coil winding machine with parallel winding of multiple coils

A wire winding machine and wire feeding technology, which is applied in the field of multi-wire parallel winding winding machines and winding machines with multiple enameled wires winding in parallel, can solve the problems of paint skin on the surface of easily damaged wires and unsmooth incoming wires, etc., and achieve structural Reasonable, winding efficiency and high quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

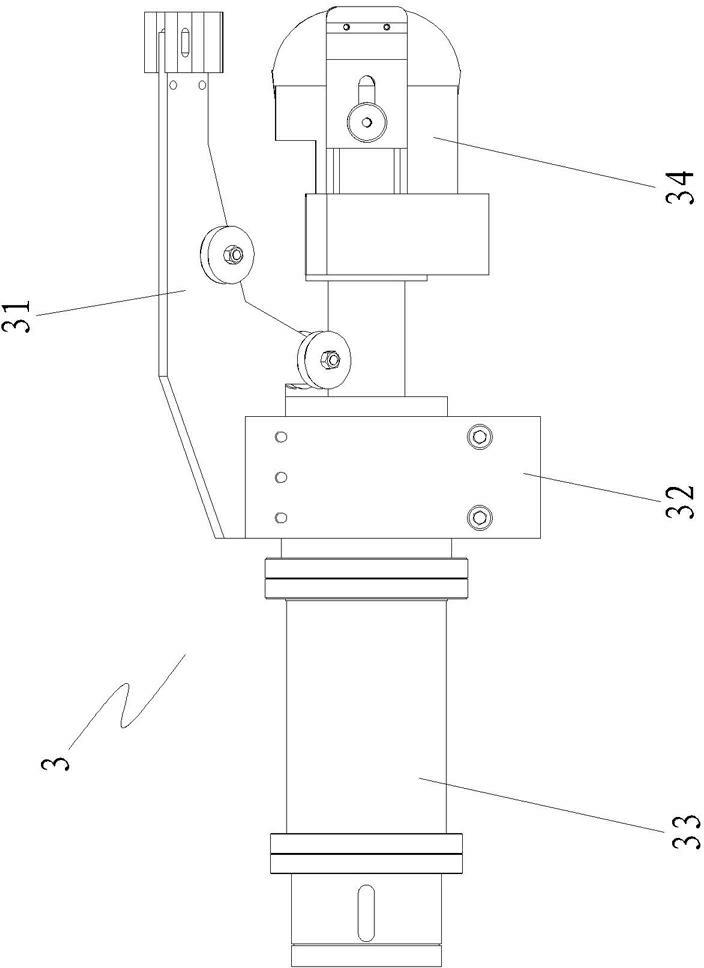

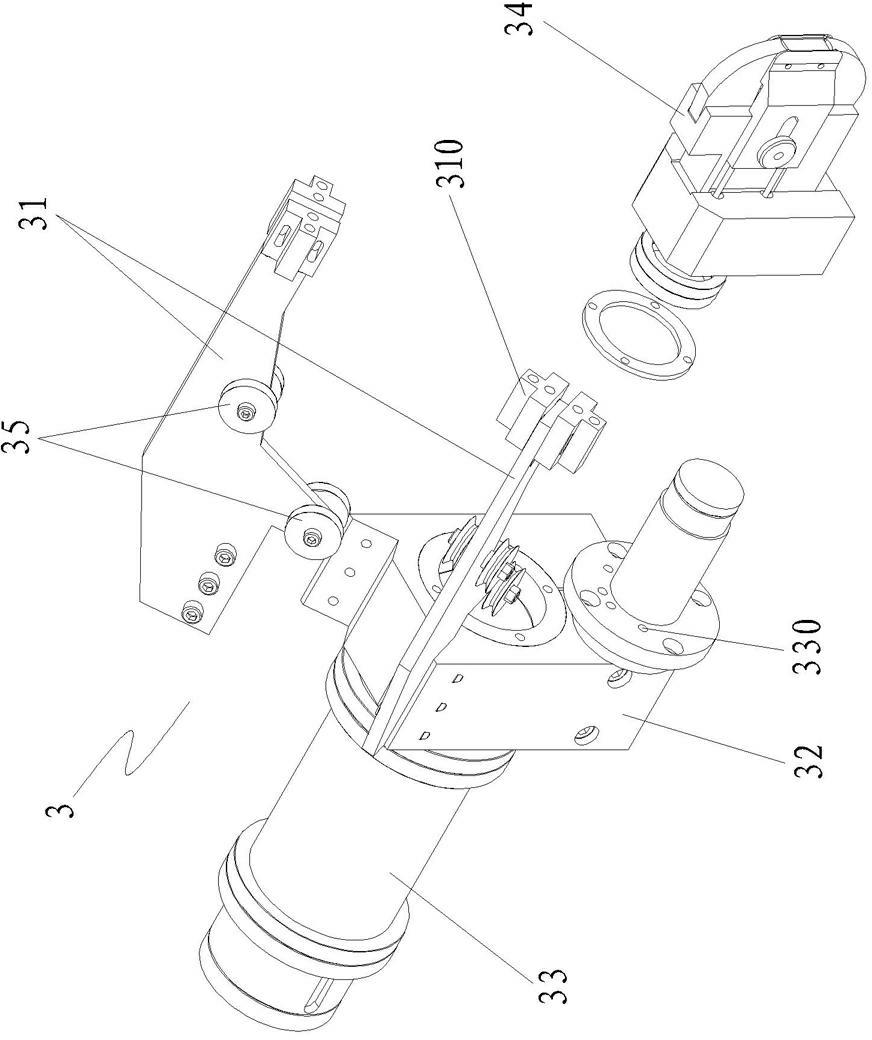

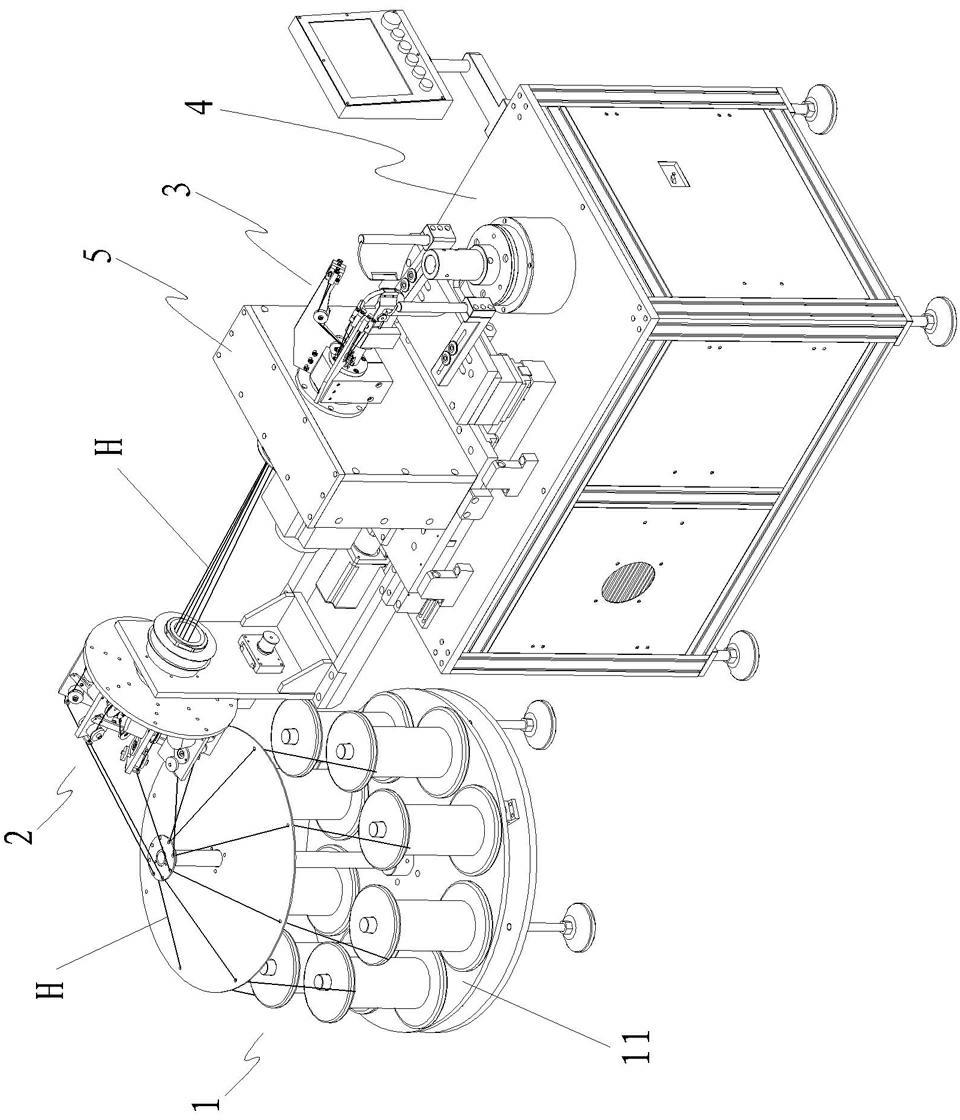

[0030] Example: see Figure 1 to Figure 7 , a multi-wire parallel winding winding machine, including a rotating wire transmission frame 1, a rotating tension device 2 and a flying fork mechanism 3, wherein:

[0031] Rotary wire transmission rack 1, which is a bracket for providing multiple wires;

[0032] Rotary tension device 2, which includes a corresponding number of tension mechanisms 21 for adjusting the tightness of each line in the conveying process;

[0033] Flying fork mechanism 4, which has one or more wire nozzles (holes) 41 for multiple wires to pass through correspondingly and make each wire enter the slot of the stator in turn;

[0034] The rotating direction and speed of the rotating wire feeding frame 1 and the rotating tension device 2 are kept in sync with the flying fork mechanism 3 to prevent the wires from being twisted together during the winding process of multiple wires.

[0035] see figure 2 , the rotary wire transmission frame 1 of the present inv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com