Flue-type denitrification reactor

A denitrification reactor and flue-type technology, applied in the field of denitrification reactor, can solve problems such as uneven flow field and prone to ash accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

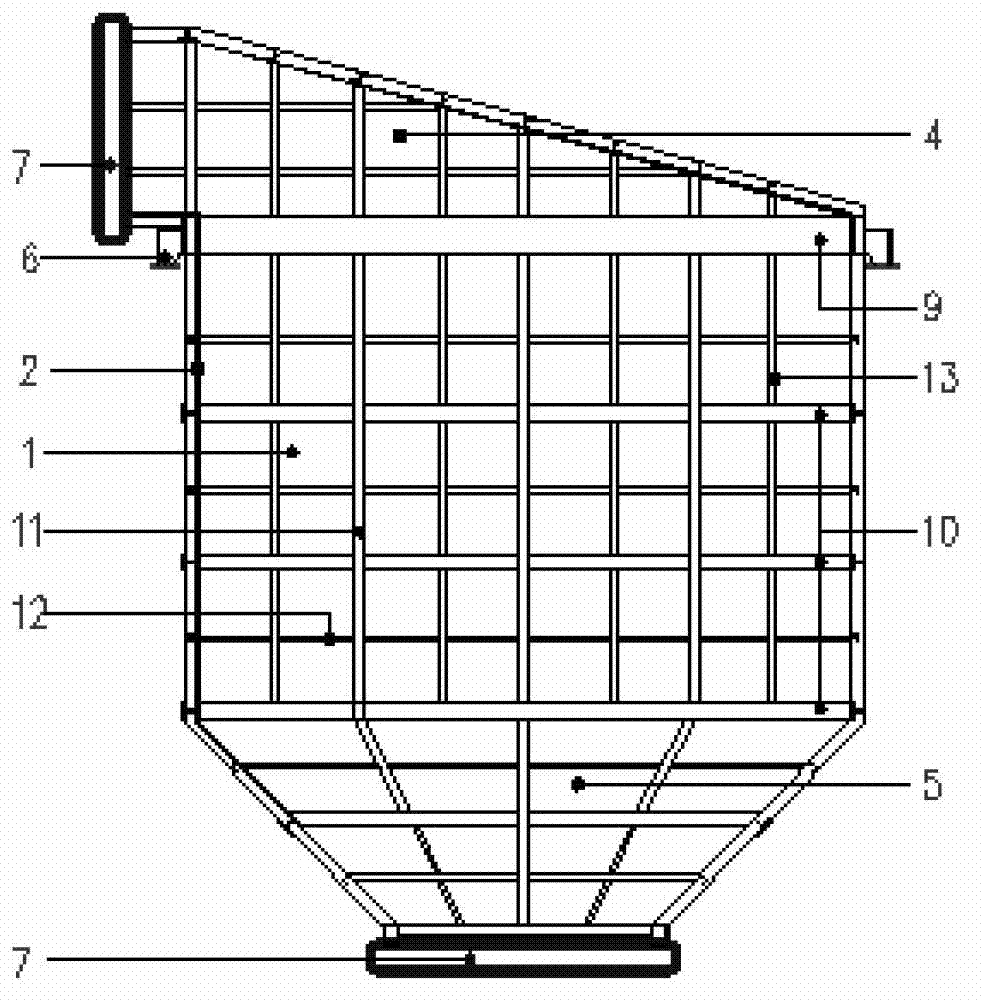

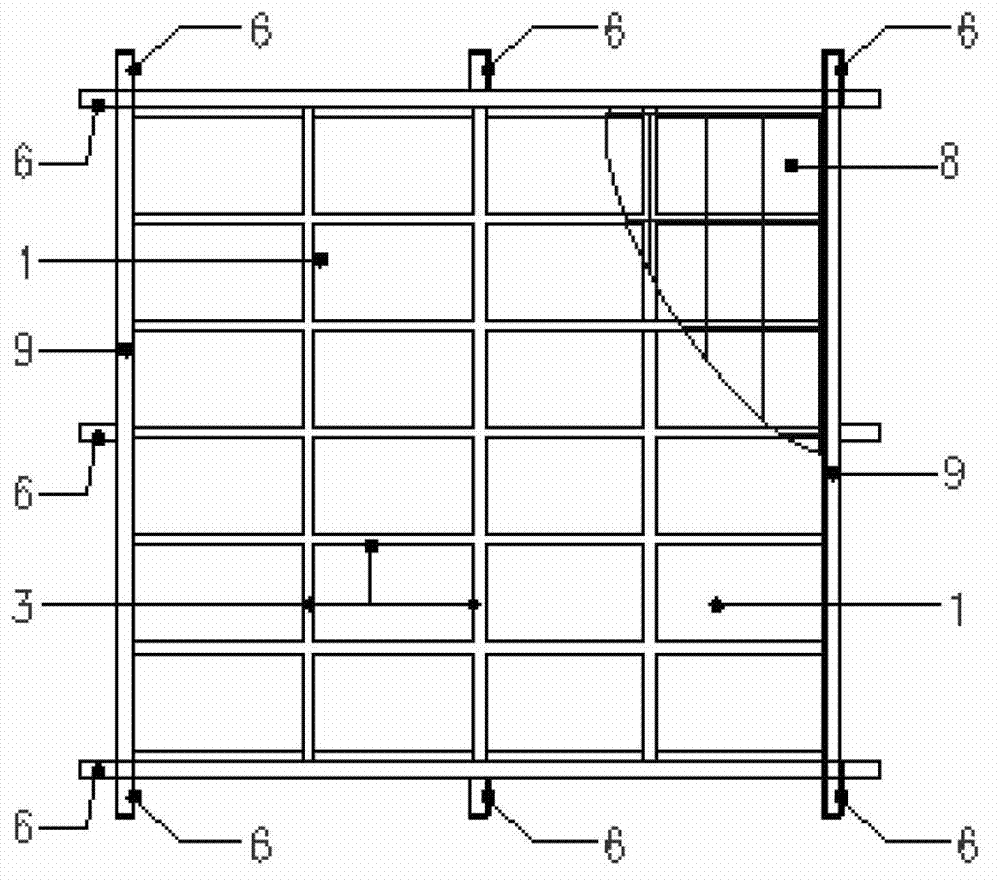

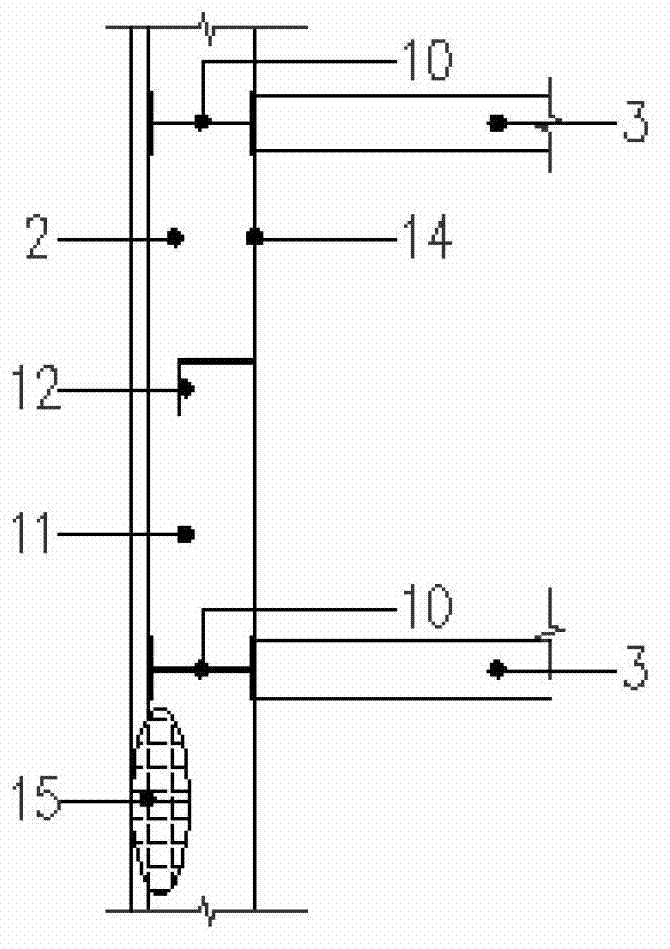

[0036] Below in conjunction with accompanying drawing, the present invention will be further described.

[0037] First analyze the stress of the reactor: the flue gas pressure inside the reactor is roughly 5.8KPa, and the design temperature is generally 400~450°C. The reactor is subjected to catalyst load, ash load, rectifier load, wind load, and temperature load , flue gas pressure and other loads. Then arrange the overall structural components of the reactor. The layout and calculation of the structural components are mainly based on the "Code for Design of Steel Structures", "Technical Regulations for Design of Smoke and Wind Coal Pipelines in Thermal Power Plants", "Design Technology for Smoke and Wind Coal Powder Pipelines in Thermal Power Plants" Complementary Design Calculation Method for Regulations” and other current norms and regulations, stress analysis calculation and design are carried out as a whole after modeling.

[0038] The reactor body needs to consider the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com