Scraper conveying device, double-toothed-rail scraper conveyor and coal mining device

The technology of scraper conveyor and conveying device is applied in the direction of driving device, transportation and packaging, slitting machinery, etc., which can solve the problems of shearer tipping, shearer body skew, shearer body jumping, etc. Achieve the effect of reducing the failure rate, avoiding uneven stress, and facilitating installation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

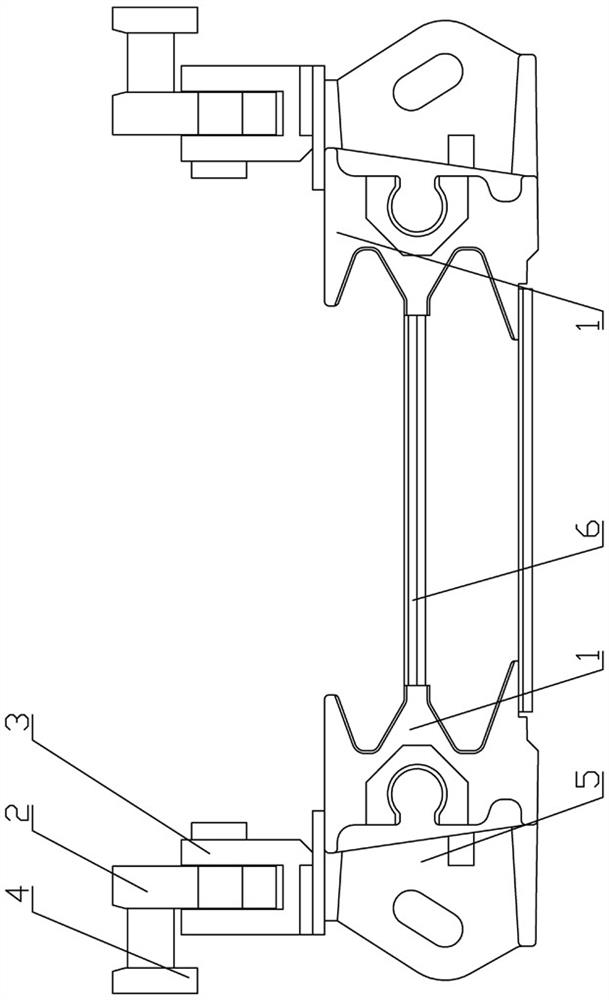

[0027] Embodiment one: as attached figure 1 As shown, the scraper conveying device includes a middle trough 6 , and rack rails 2 are fixedly installed on the sides 1 of the middle trough 6 via rack rail seats 3 .

[0028] According to requirements, the middle tank 6 includes a middle plate in the middle for carrying pulverized coal, a tank side 1 arranged on the left and right sides of the middle plate, and a bottom cover plate arranged under the middle plate, and the gear rail 2 is fixedly installed on the upper side of the tank side 1 . During use, by setting the rack 2, the shearer can walk on the scraper conveying device through the rack wheel 11, so as to avoid the phenomenon of uneven stress, jamming and inability to walk smoothly when the shearer is working, and can Improve coal mining efficiency and facilitate installation and maintenance.

[0029] According to actual needs, the above scraper conveying device can be further optimized or / and improved:

[0030] as att...

Embodiment 2

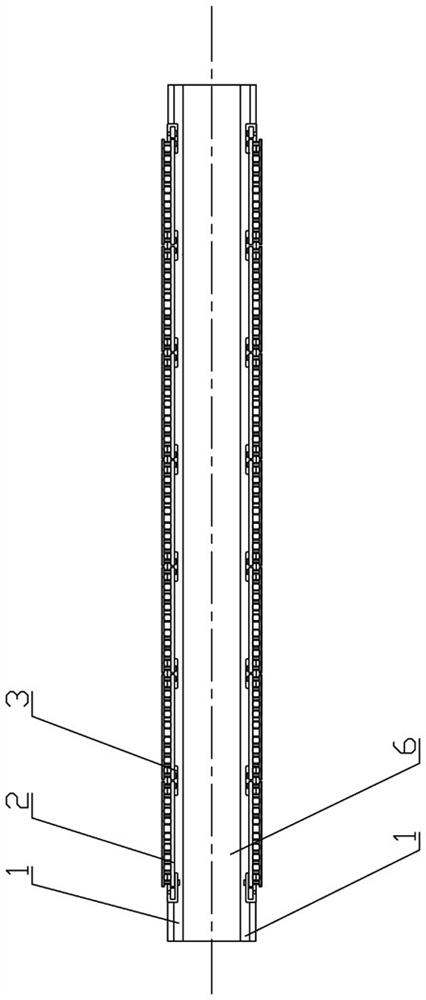

[0034] Embodiment two: as attached figure 2 As shown, the double rack scraper conveyor includes a head transmission part, a transition groove, an adjustment groove, a tail part and a middle groove body formed by a plurality of middle grooves 6 fixedly connected together, the head transmission part, the transition groove, The regulating tank, the middle tank body and the machine tail are connected together.

[0035] According to requirements, the transmission part of the head, the transition groove, the adjustment groove and the tail part are all existing known technologies. In the process of use, through such a setting, the middle trough can be produced in batches and installed in combination to form a double rack scraper conveyor, which can be combined with the coal mining machine with cutting drums on one side and the coal mining machine with cutting drums on both sides. The shearer is used in conjunction with the machine so that the shearer moves forward or backward on th...

Embodiment 3

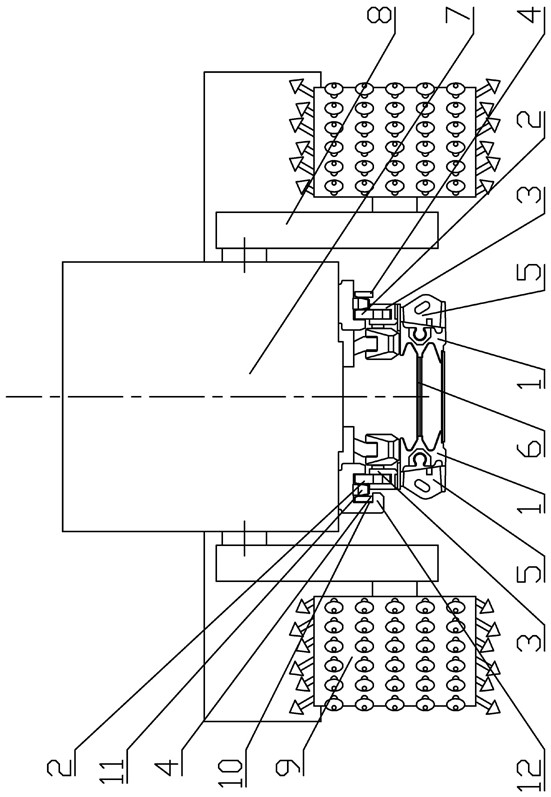

[0036] Embodiment three: as attached image 3 As shown, the coal mining device includes a coal mining machine body and a double rack scraper conveyor. The coal mining machine body includes a coal mining machine body 7, a coal mining machine rocker arm 8 and a coal mining machine cutting drum 9. The left and right sides of the machine body 7 are provided with a shearer cutting drum 9, the shearer cutting drum 9 is connected with the shearer body 7 through the shearer rocker arm 8 and can swing up and down, and the middle groove 6 is arranged in the On the lower side of the shearer fuselage 7 at the position between the cutting drums 9 of the shearer, on one side of the lower part of the shearer fuselage 7 there is a detaining groove 10 with an opening downward, and in the middle of the detaining groove 10, a The rack wheel 11 engaged with the rack 2, the rack 2 is located in the holding groove 10, and the rack wheel 11 engaged with the rack 2 on the other side is provided on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com