Motorbike tire segmental mold structure for plate vulcanizing machine

A flat vulcanizing machine and flexible mold technology, which is applied to household appliances, other household appliances, tires, etc., can solve the problems of uneven force on the upper cover, inability to open and close the mold, and great safety hazards, so as to achieve smooth opening and closing of the mold. , to avoid the effect of unsmooth movement and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

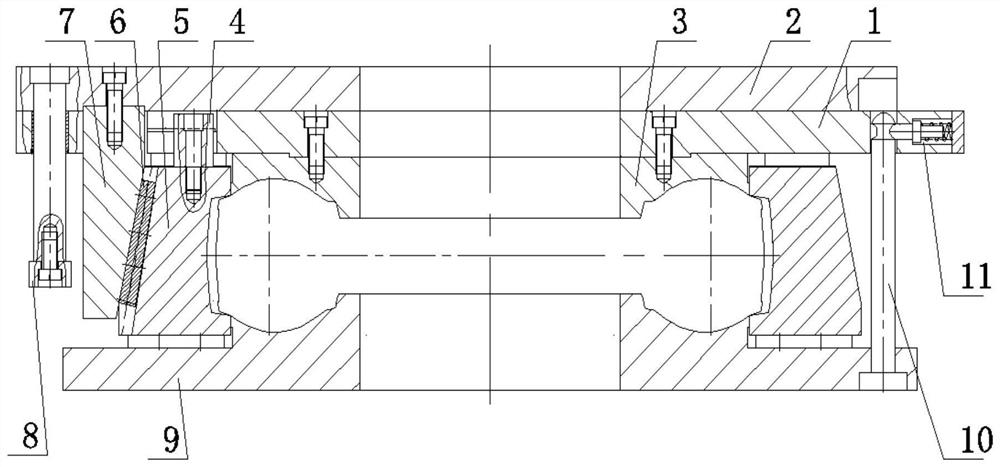

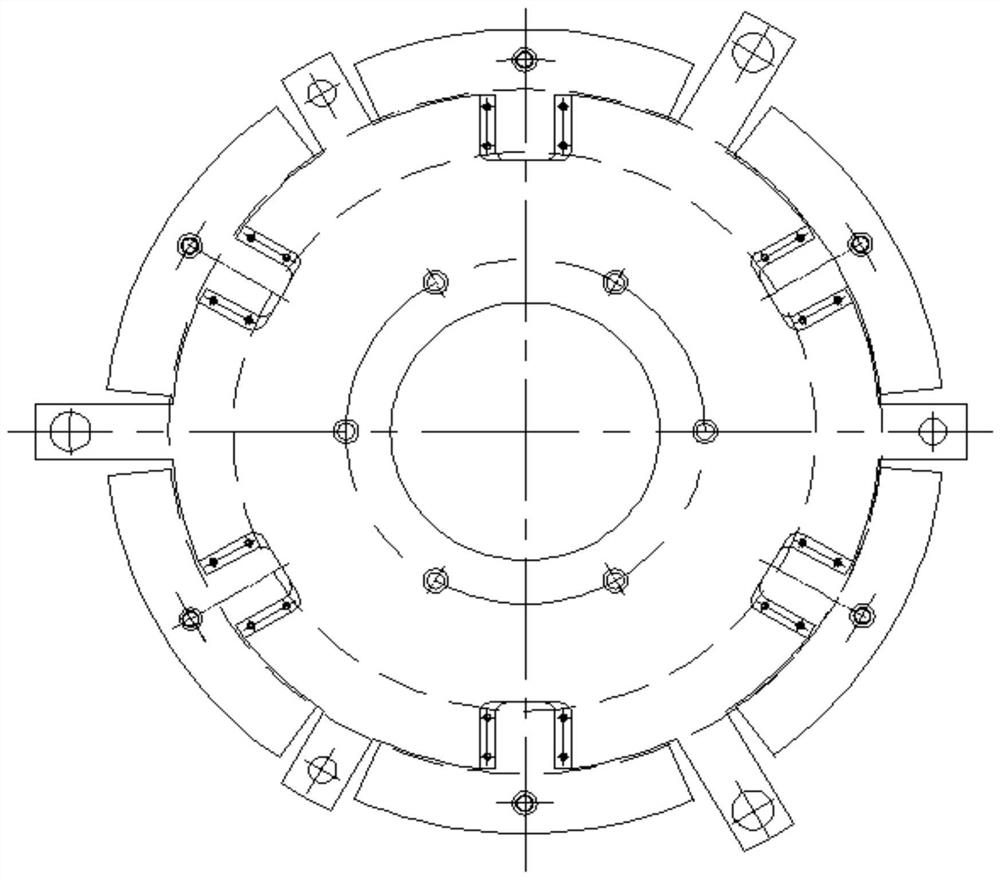

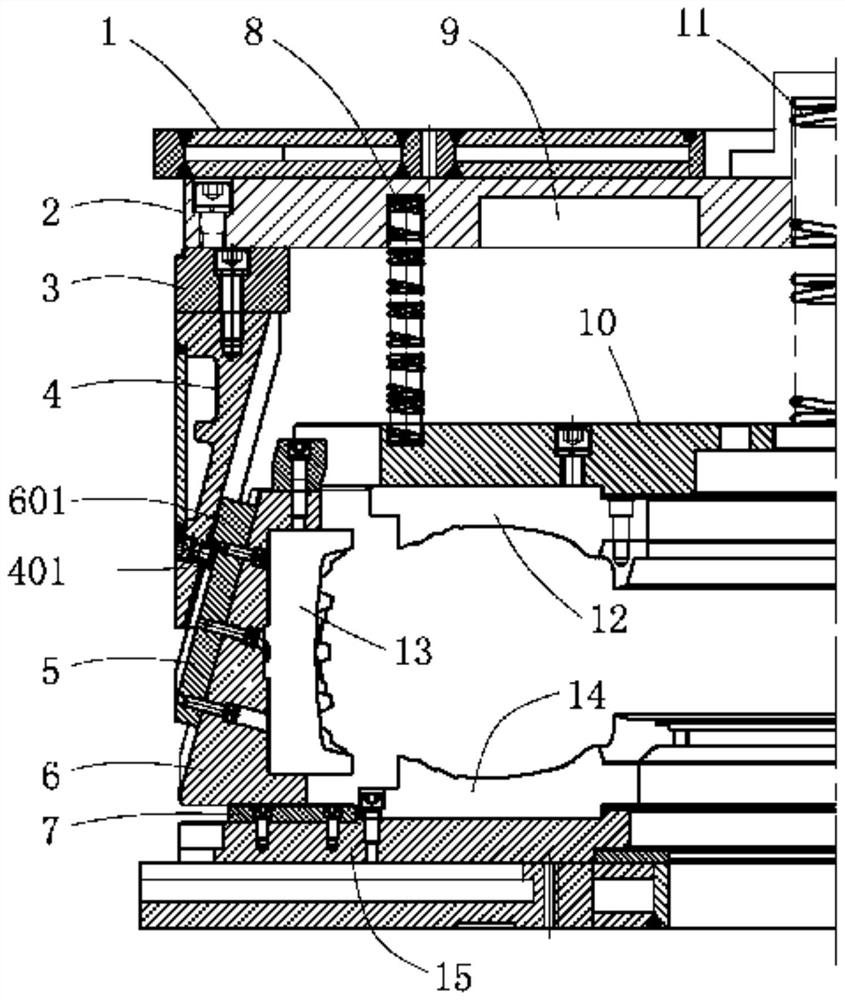

[0027] combine figure 1 , figure 2 As shown, the present invention relates to a motorcycle tire movable mold structure for a flat vulcanizer, which consists of an upper cover plate, an upper cover, an upper side plate, a T-shaped block, a pattern block, a guide strip, a pattern block locking wedge, a base , distance rod, sequence rod and sequence rod limiting device. The pattern block locking wedge is a single-piece structure and is embedded in the upper cover plate for positioning. The number of pattern block locking wedges and pattern blocks is the same. The pattern block locking wedge adopts electric heating; the dist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com