Radial tire steel wire ring cloth wrapping winding machine and realization method thereof

A radial tire and bead ring technology, which is applied to tires, other household appliances, household appliances, etc., can solve the problems of inability to achieve various specifications of bead rings with various densities, thin wrapping, and dense wrapping. The effect of good wrapping quality, compact device structure and stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the above objectives, features and advantages of the present invention more obvious and understandable, the present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

[0028] The specific structure of the present invention is as follows:

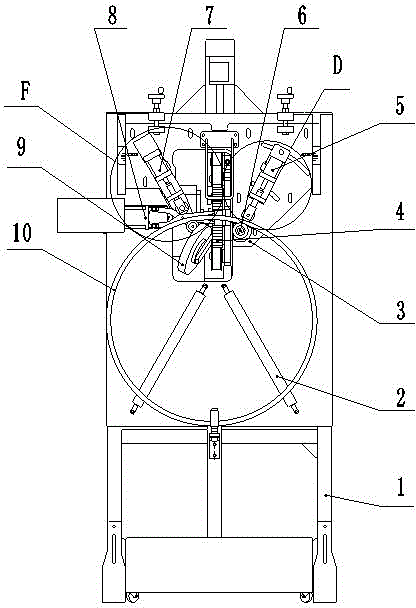

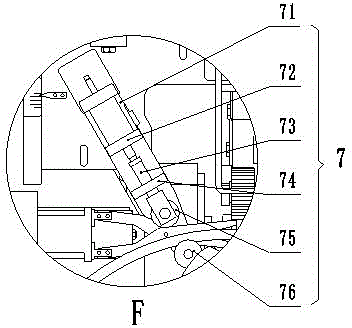

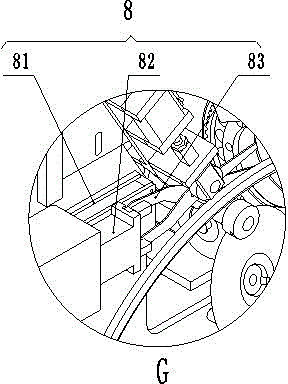

[0029] Combine Figure 1~10 As shown, a radial tire traveler cloth wrapping machine is shown, which includes a lightweight main frame 1, a side positioning device 2, a height adjustment device 3, a cloth protection roll rotation device 4, a right pressing device 5, and a traveler Rotating device 6, left pressing device 7, automatic shearing device 8, fabric protection roll 9, traveler 10, side positioning device 2 is installed under the lightweight main frame 1; the height adjustment device 3 is locked to the lightweight main frame 1 The upper part; the cloth guard roll rotation device 4 is installed at the middle position of the upper end of the ligh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com