Cable processing and winding machine and operating method thereof

A winding machine and cable technology, applied in the direction of conveying filamentous materials, thin material processing, transportation and packaging, etc., can solve the problems of high labor intensity, cable wear, low work efficiency, etc., to improve quality, reduce wear, and efficiency. improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

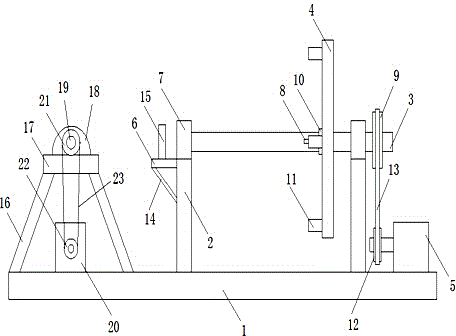

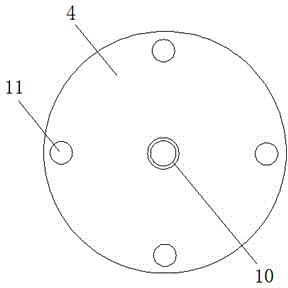

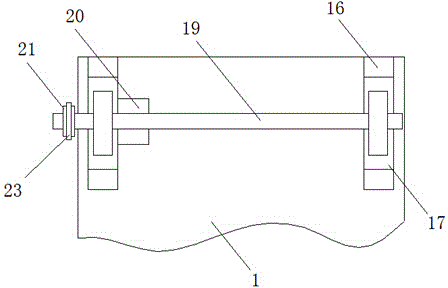

[0015] As shown in the accompanying drawings: a cable processing and winding machine, the cable processing and winding machine includes two parts: a winding device and a recovery device, and the winding device and the recovery device are both arranged on the bottom plate 1, and it is characterized in that: the winding device The device includes a bracket one 2, a winding shaft 3, a rotating disk 4, a motor one 5 and a fixed plate 6, the bracket one 2 is arranged on the bottom plate 1, and a bearing one 7 is arranged on the bracket one 2. Both ends of the shaft 3 are arranged in the bearing one 7, and the winding shaft 3 is provided with a lead hole 8 and a driven wheel one 9. The winding shaft 3 is set to a hollow structure, and the cable is inserted into the lead hole 8, and the hollow The transmission is carried out in the winding shaft 3, which reduces the wear of the cable by the processing winding machine and improves the quality performance of the cable. The rotating disc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com