Winding machine for chemical fiber production

A winding machine and chemical fiber technology, which is applied in the direction of conveying filamentous materials, thin material processing, transportation and packaging, etc., can solve the problems of winding roller stuck, short lines, inconvenience, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

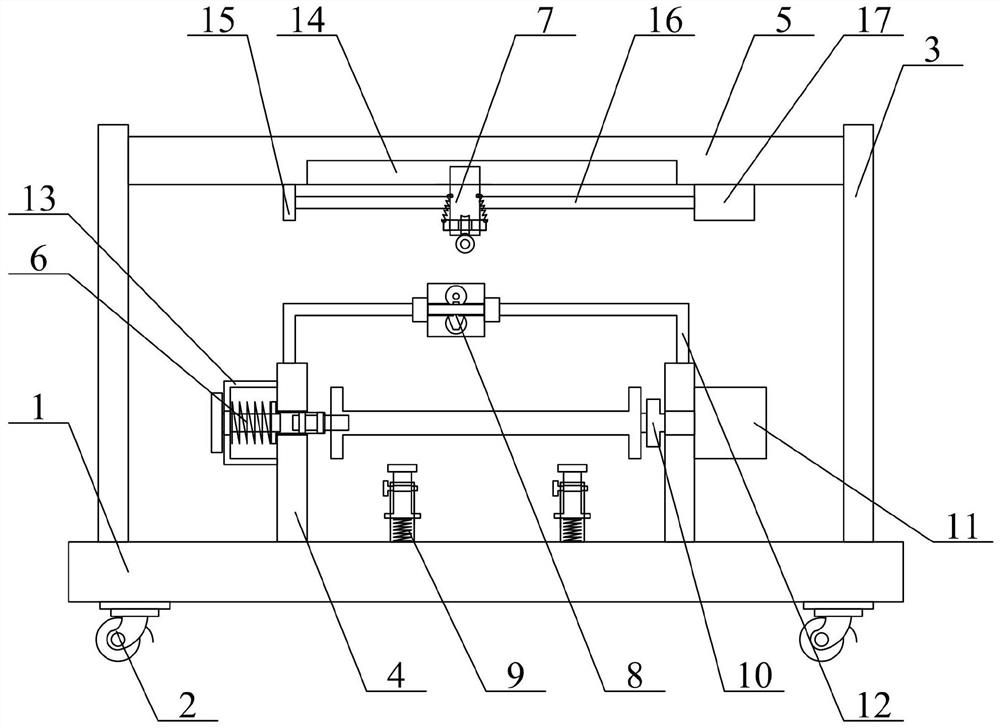

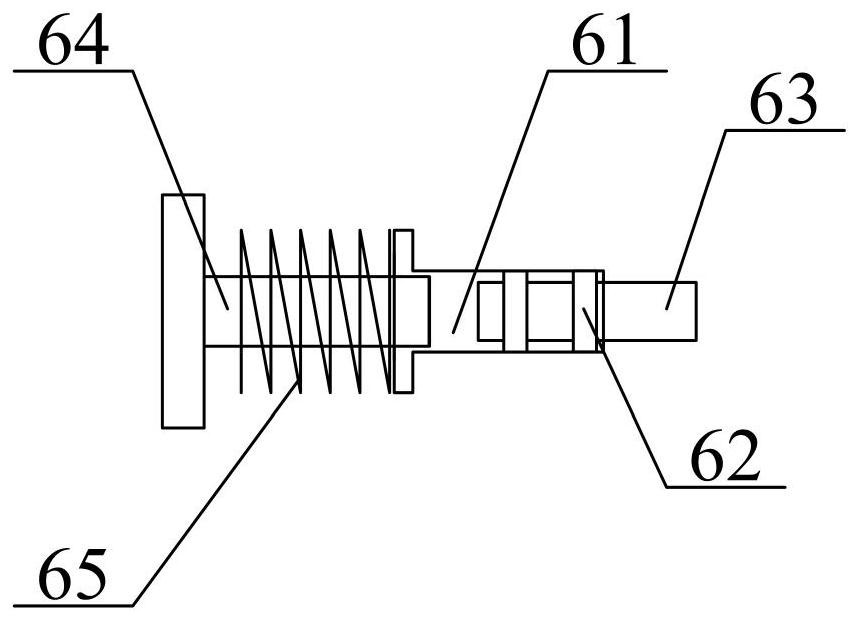

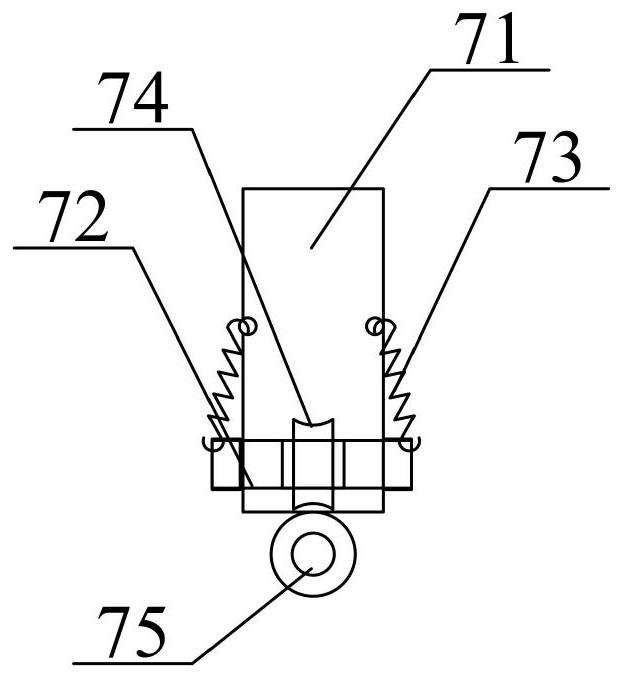

[0035] The present invention is described in detail below in conjunction with accompanying drawing, as appended figure 1 And attached figure 2 As shown, a winding machine for producing chemical fibers includes a base 1, a movable brake wheel 2, a first support plate 3, a first fixed plate 4, a support beam 5, a structure 6 that can be buffered and pulled and inserted into a rotating rod, and can be reciprocally guided and buffered. Frame structure 7, slidable protective box structure 8, supportable protective buffer rod structure 9, inclined T-shaped transmission tube 10, winding motor 11, inverted U-shaped frame 12, U-shaped connecting frame 13, sliding groove 14, second fixation Plate 15, reciprocating threaded pipe 16 and guide motor 17, the moving brake wheels 2 are respectively bolted to the four corners of the lower end of the base 1; side; the lower ends of the first fixing plate 4 are respectively bolted to the middle of the upper end of the base 1; The described st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com