Efficient winding equipment for clothing materials

A high-efficiency and equipment technology, applied in the cutting of textile materials, winding strips, processing of thin materials, etc., can solve the problems of low work efficiency and cumbersome operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

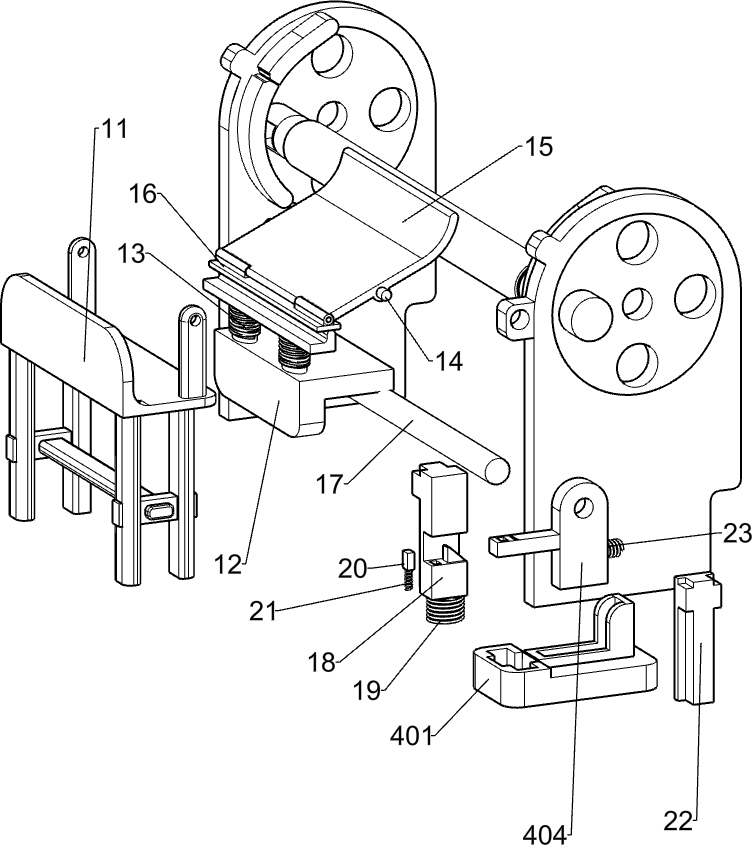

[0028] Efficient winding equipment for clothing materials, such as Figure 1 to 4 As shown, including the bottom plate 1, the support frame 2, the strobe rod tensioning mechanism 3 and the rolling mechanism 4, and the bottom plate 1 is connected to the left and right sides of the bottom plate 2, and the support frame 2 is provided with a winding bar tensioning mechanism. 3. The winding rod tensioning mechanism 3 is provided with a rolling mechanism 4 between the bottom plate 1.

[0029] When the clothing material is needed, the user can fix one end of the clothing material on the receiving rod tensioning mechanism 3, which is then controlled to start working, thereby controlling the winding bar tensioning mechanism 3 to carry out the clothing material. Requested, when the clothing material is complete, the clothing material can be cut off. When all the clothing materials are finished, the rolling mechanism 4 can be controlled to stop the work.

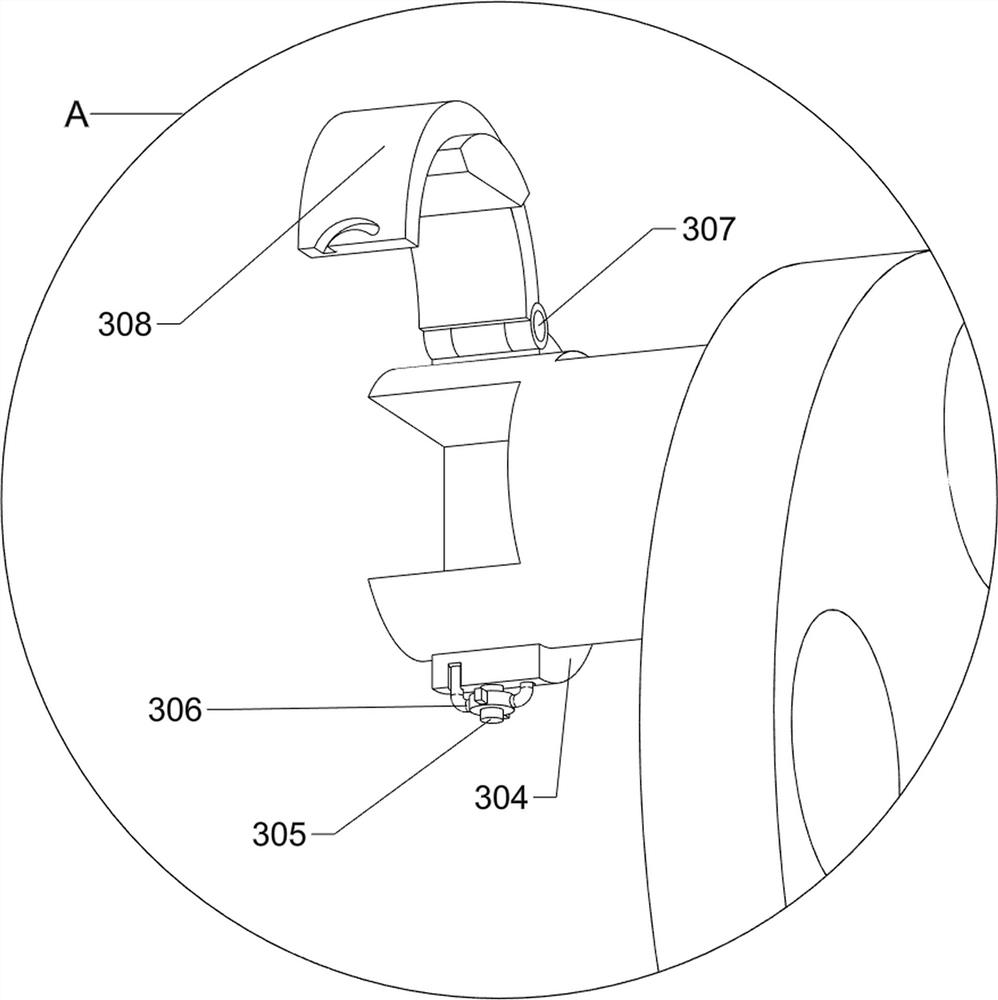

[0030] The receiving rod tensioning ...

Embodiment 2

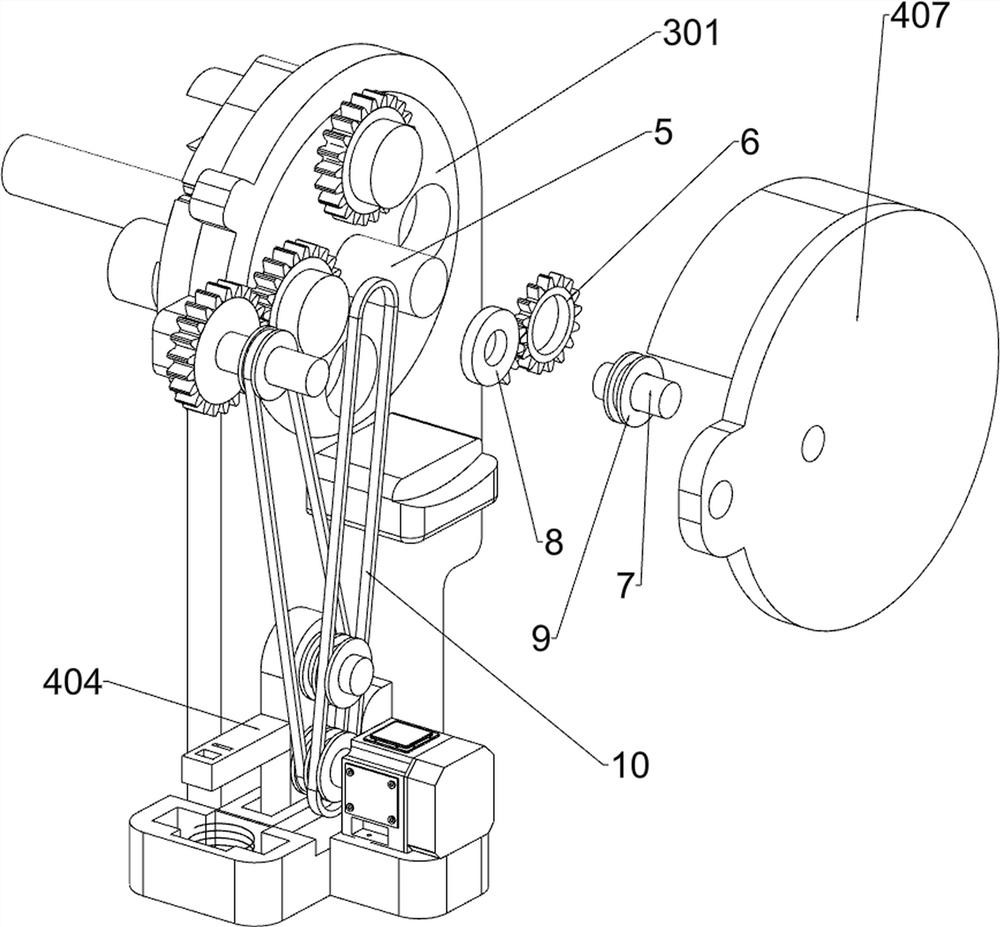

[0035] On the basis of Example 1, such as Figure 5 to 8 The fifth axis 5, the third gear 6, the sixth axis 7, the shorter waters 8, the fourth pulley 9, and the second flat belt 10 are connected to the right side of the support turntable 301, and there is a fifth axis 5. The third gear 6 is connected to the fifth axle 5, and the rotating housing 407 is provided with the sixth axis 7, and the second rotating shaft 7 is connected to the shortex 8, the shortex 8 is engaged, the sixth axis The fourth pulley 9 is provided, and a second flat belt 10 is provided between the first pulley 403 and the fourth pulley 9, and the second flat belt 10 is fitted to the second pulley 406.

[0036] After the first receiving rod 309 is completed by the winding material, the shaft seat 404 can be controlled forward, and the shaft seat 404 is smoothly moved to drive the third axis 405 and the second pulley 406 forward, the second The pulley 406 is forwarded to make the first flat belt 410 becomes a rel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com