Quick air-cooled heat radiation type controller

A controller, heat dissipation technology, applied in cooling/ventilation/heating transformation, electrical components, electrical equipment structural parts, etc., can solve the problems of slow wind speed, poor cooling effect, large resource consumption, etc. The effect of long service life and low resource consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

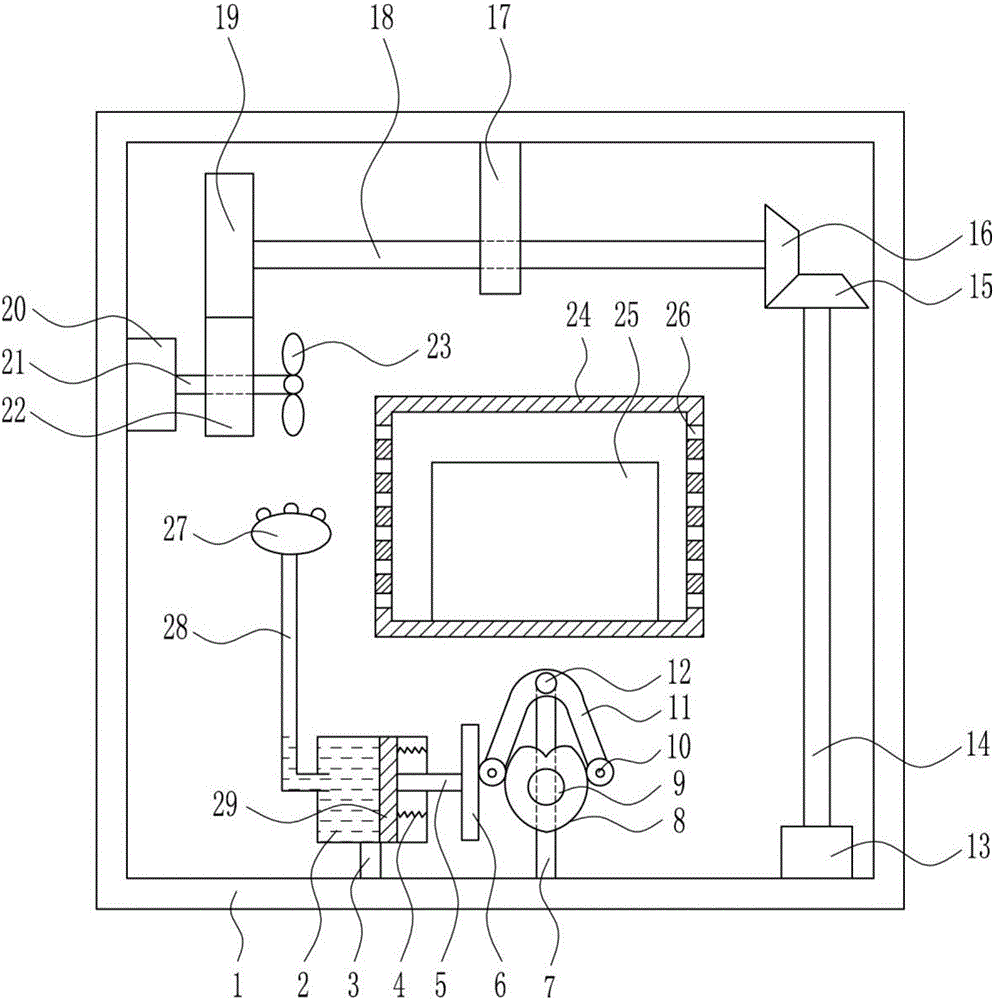

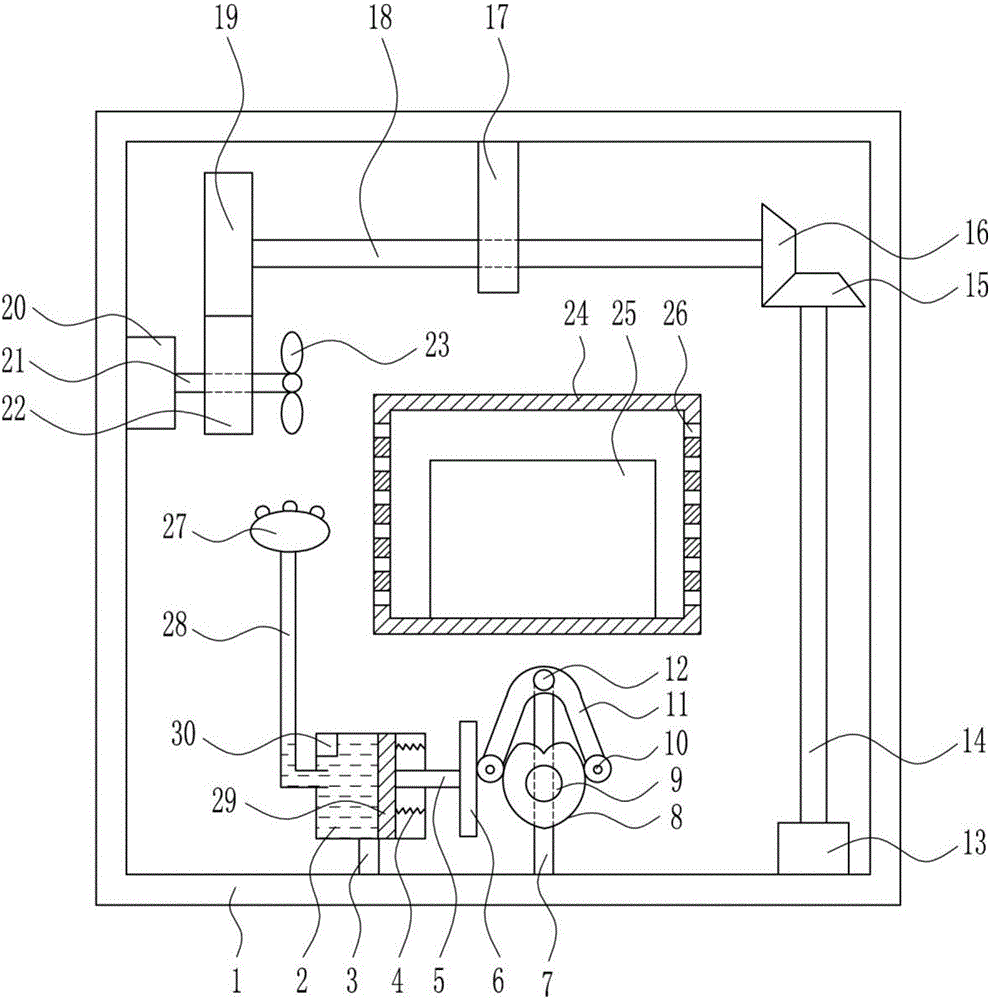

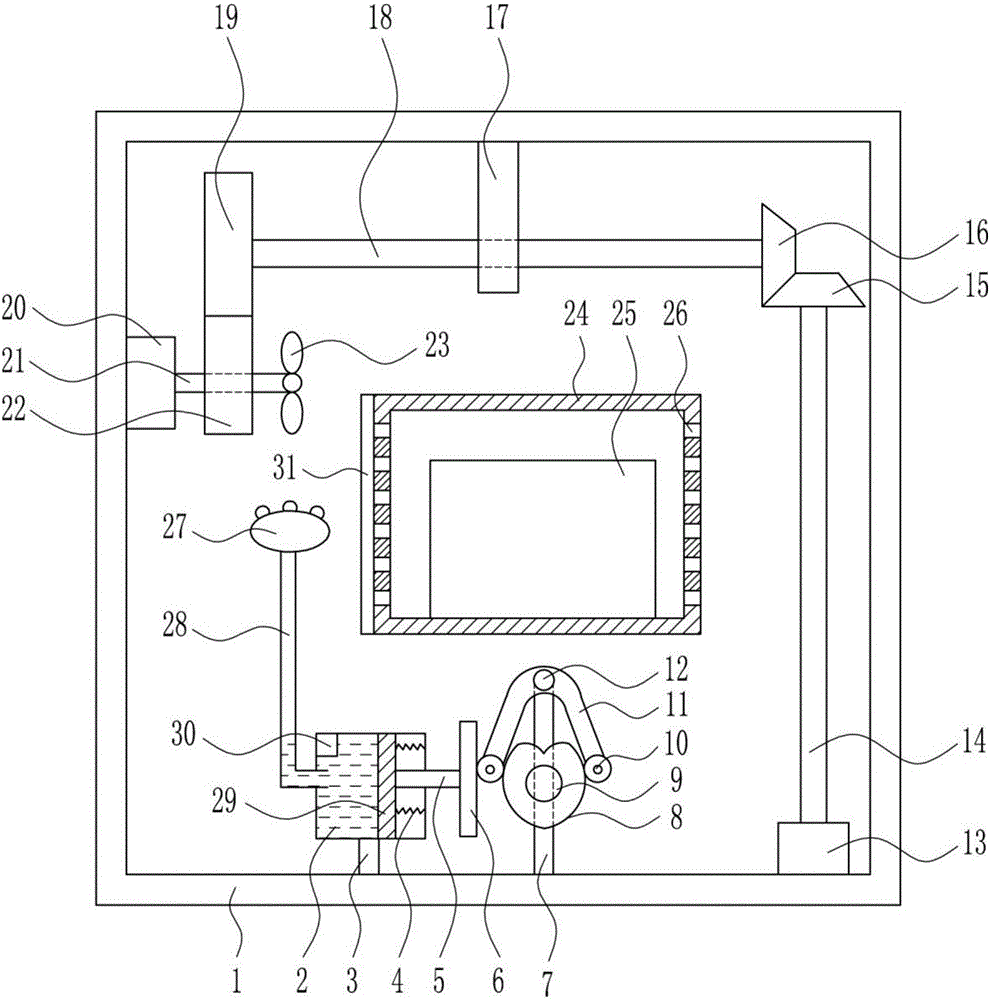

[0031] A fast air-cooled heat dissipation controller, such as Figure 1-4 Shown, include placement box 1, water tank 2, first pole 3, spring 4, connecting rod 5, push plate 6, second pole 7, equal diameter cam 8, first motor 9, contact roller 10, crank Shape bar 11, the first rotating shaft 12, the second motor 13, the second rotating shaft 14, the first bevel gear 15, the second bevel gear 16, the upper bearing seat 17, the third rotating shaft 18, bull gear 19, left bearing seat 20, The fourth rotating shaft 21, pinion 22, blade 23, storage box 24, controller 25, nozzle 27, hard water pipe 28 and piston 29; the bottom of the storage box 1 is provided with the first pole 3, The second pole 7 and the first motor 9, the top of the first pole 3 is provided with a water tank 2, the left wall of the water tank 2 is provided with a hard water pipe 28, the upper end of the hard water pipe 28 is provided with a nozzle 27, and the water tank 2 is provided with a piston 29 A spring 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com