Multifunctional horizontal type aluminum wire enamelling machine

A kind of enamelling machine and multi-functional technology, which is applied in the direction of conductor/cable insulation, electrical components, circuits, etc., and can solve the problems of difficult cleaning, breaking, and varnish of softening pipes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

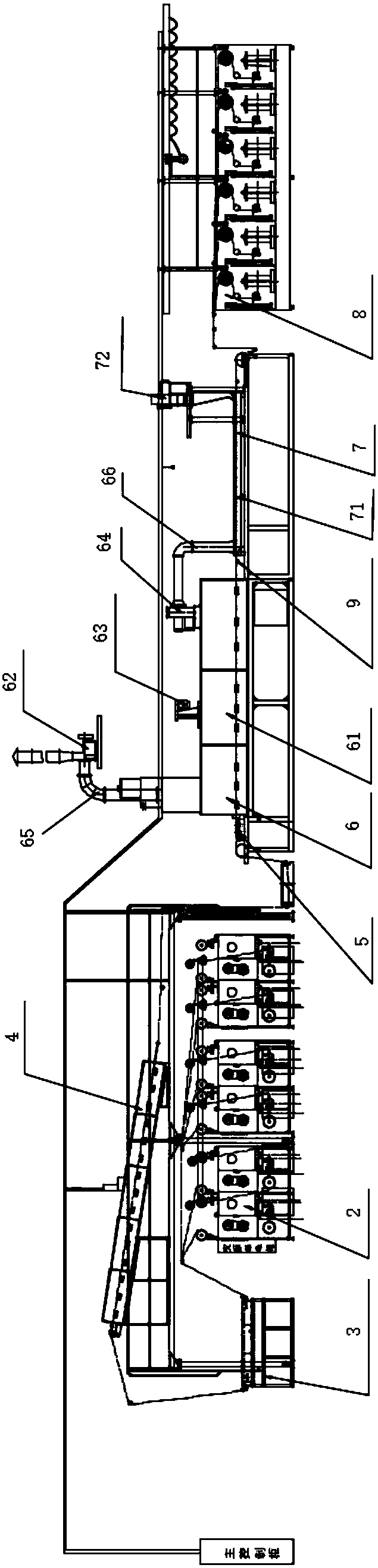

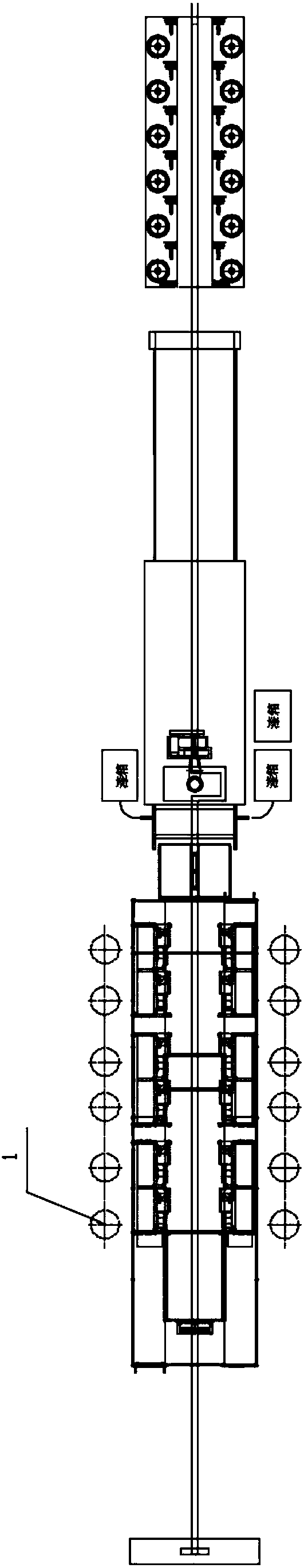

[0033] Examples, see Figure 1-10 , the multifunctional horizontal aluminum wire enamelling machine provided in this embodiment includes a wire releasing device 1, a wire drawing device 2, a cleaning device 3, an annealing furnace 4, a painting device 5, an oven 6, a cooling device 7, and a wire receiving device 8 .

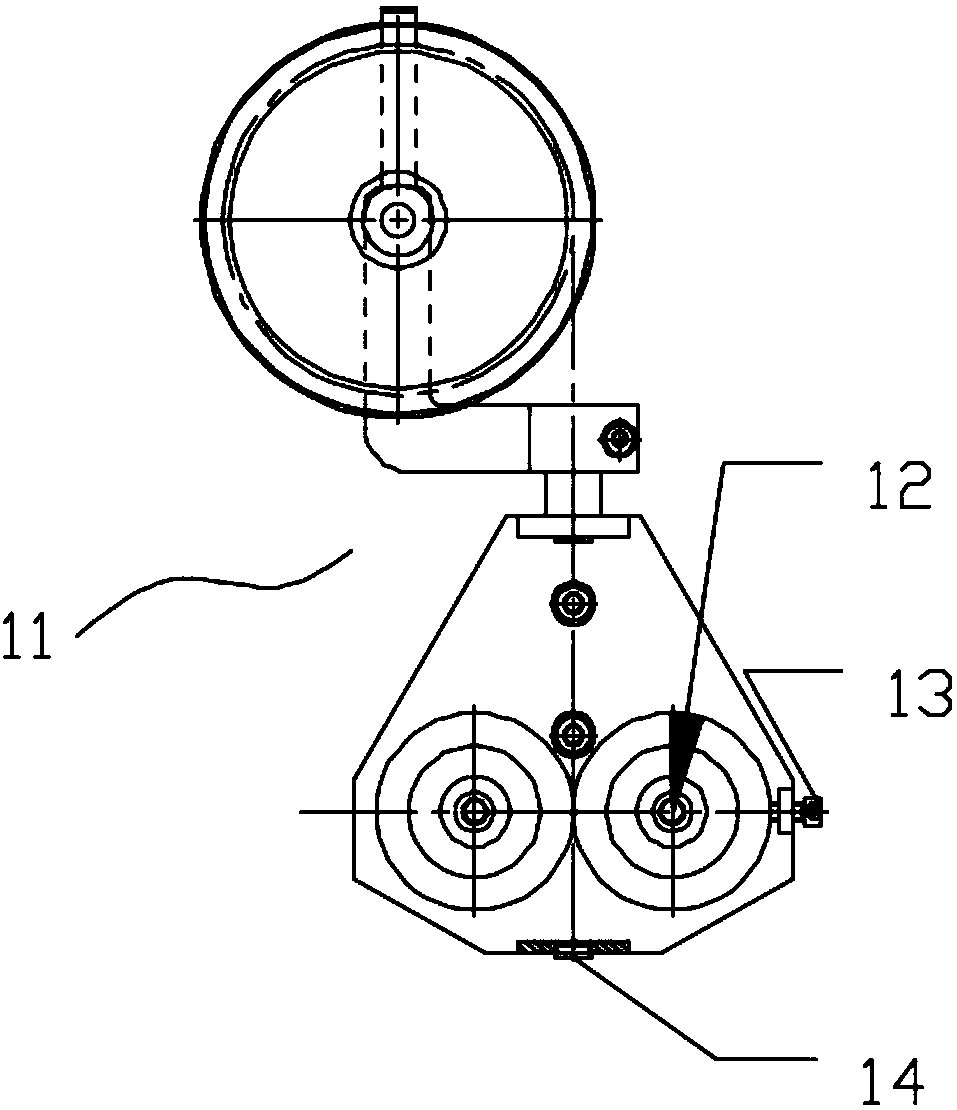

[0034] The pay-off device 1 is arranged on the side of the wire drawing device 2, and the pay-off device 1 includes one or more pay-off machines 11, and the pay-off machine 11 includes two soft wheels 12, adjusting screws 13, porcelain guides 14 and the wire retaining plate 15, the axes of the two soft wheels 12 and the adjusting screw 13 are located on the same horizontal line. The wire is pressed and braked to realize that the bare wire is in a tensioned state.

[0035] The wire drawing device 2 includes at least one wire drawing machine 21, two or more wire drawing machines 21 are arranged side by side or between the cleaning device 3 and the annealing furna...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com