Cloth inspecting machine

A fabric inspection machine and machine technology, applied in the field of fabric inspection machines, can solve the problems of polyester fabrics being easy to close together, missed inspection, slow work efficiency, and workers are prone to fatigue, etc., to achieve reasonable design layout, ensure accuracy, Guarantee the effect of winding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

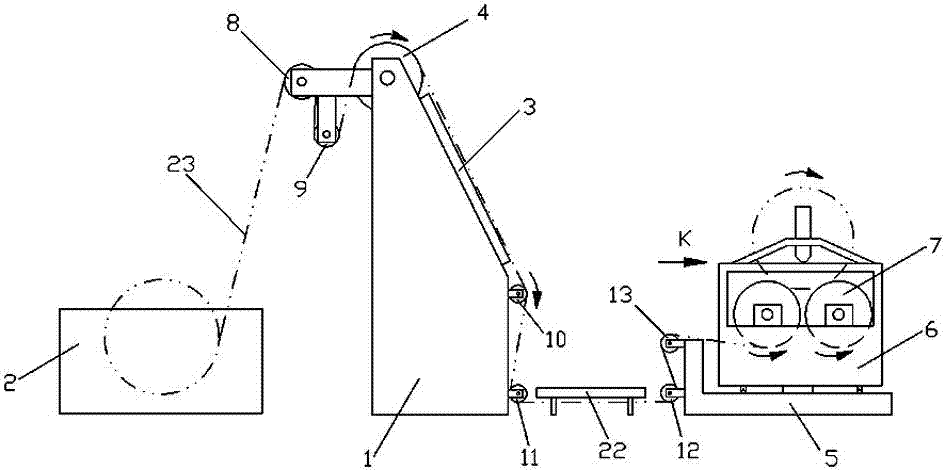

[0018] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below through specific embodiments and related drawings.

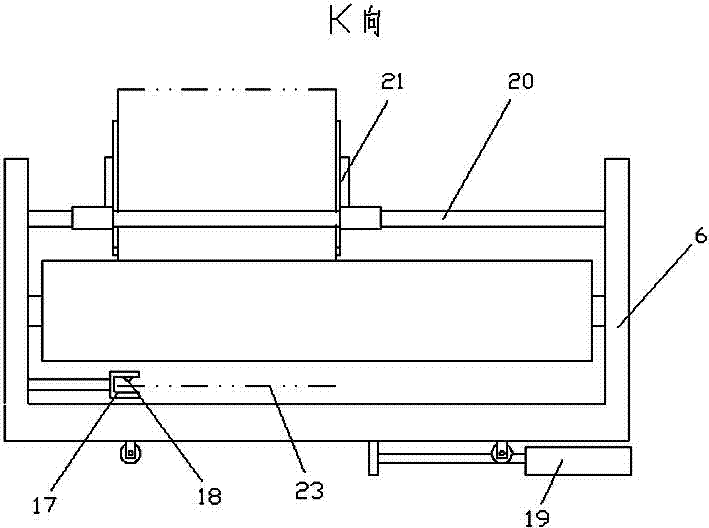

[0019] Such as Figure 1~5 As shown, a cloth inspection machine includes a machine platform 1, a trough 2 located at the rear of the machine platform 1, and a cloth rolling device located in front of the machine platform 1. The front side of the machine platform 1 is provided with an inclined light board 3, and the machine A cloth feeding roller 4 is arranged above the light board 3 on the table 1; the cloth rolling device includes a base 5, and a seat frame 6 that can slide left and right relative to it is provided on the base 5, and the seat frame 6 There is a pair of cloth rolls 7 that rotate synchronously and turn to the same direction to carry the polyester cloth reel that has been inspected. Under the light of the lamp panel, the polyester cloth can be v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com