Head-feed combine harvester

A Combine Harvester, Semi-Feed Technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

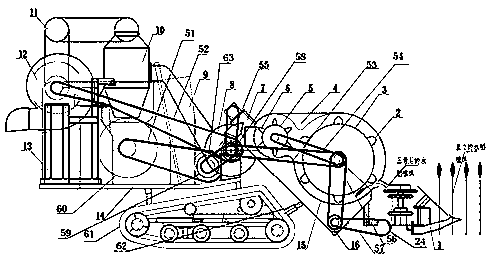

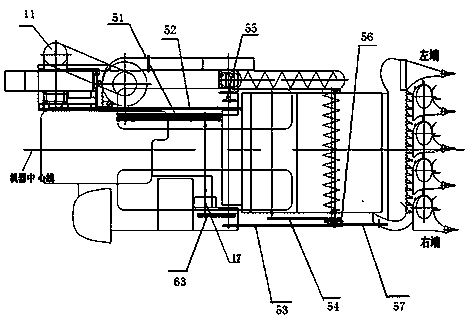

[0031] Semi-feeding combine harvester of the present invention, as figure 1As shown, it includes a walking chassis and a harvesting and threshing system, and the walking chassis includes a complete machine frame 14 , a crawler-type walking structure 61 and a power system 60 . The whole machine frame 14 is fixedly installed on the crawler type walking structure 61 as the bearing device of the whole chassis, and the power system 60 is fixedly installed on the whole machine frame 14 . The harvesting and threshing system sequentially includes a relatively fixed semi-feeding header 1, a threshing device 4, a bottom horizontal auger 16, and a side inclined auger 7. The threshing device 4 is located at the rear side of the semi-feeding type header 1 for the convenience of threshing the batch-bent rice. Fall into the transportation range of the bottom horizontal auger 16 by natural gravity, and then arrive at the next working node through the transportation of the bottom horizontal a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com