Edge peeling mechanism for knitwear rolling and inspecting machine

A technology for textile and edge stripping, applied in the field of edge stripping mechanism, can solve the problems that plague knitted textile manufacturers, patent and non-patent literature is not given, and the quality of rope-like curling and stripping is difficult to guarantee, and it can achieve excellent results. Stripping efficiency, excellent stripping effect, guaranteeing the effect of winding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

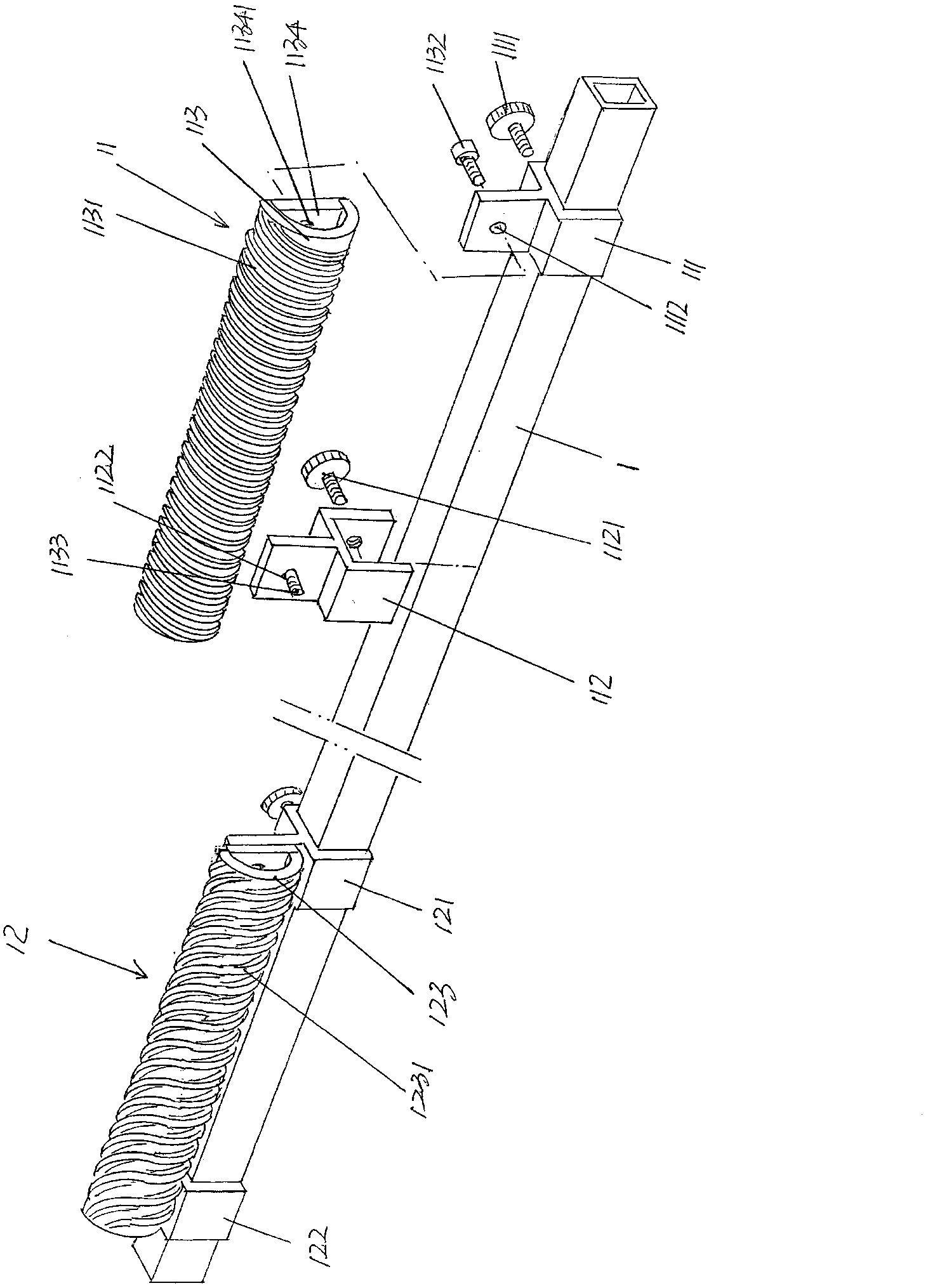

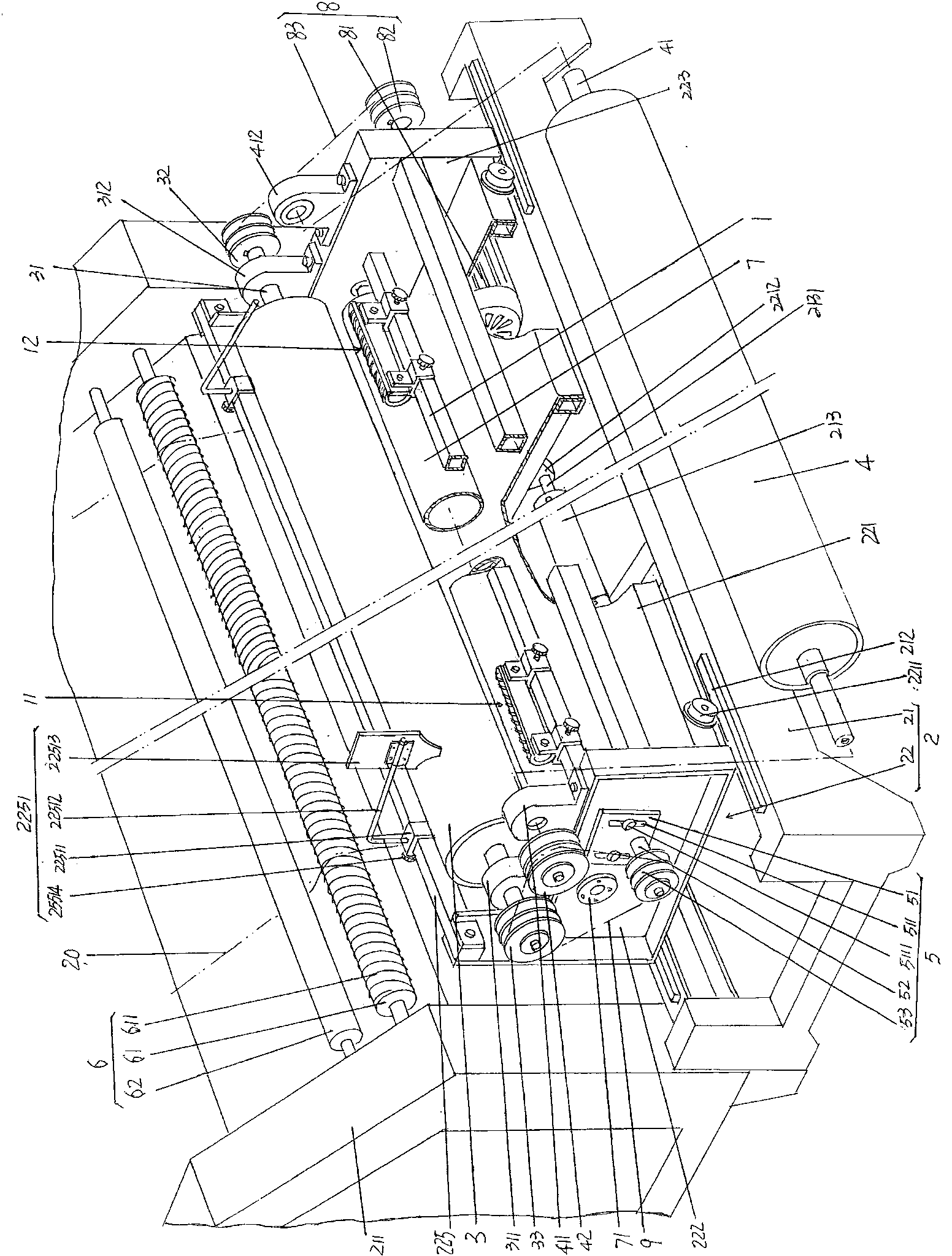

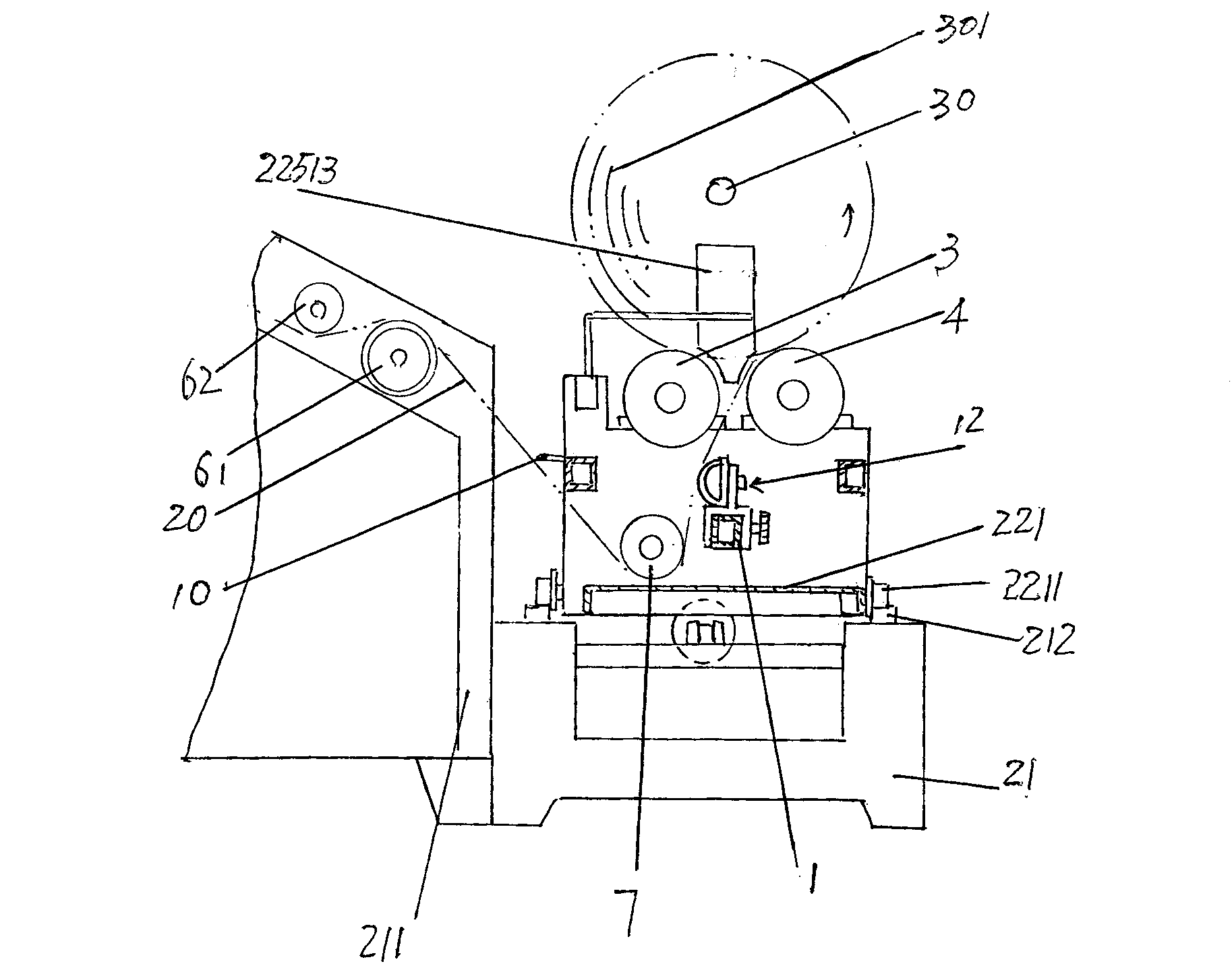

[0016] See figure 1 , provides a fixed rod 1, the cross-sectional shape of the fixed rod 1 is preferably rectangular, in this embodiment, the fixed rod 1 is served by a rectangular tube, more precisely, the fixed rod 1 is served by a square tube.

[0017] currently by figure 1 The position state shown is an example, a first edge stripping mechanism 11 is arranged at one end of the fixed rod 1 in the length direction, that is, the right end, and a second edge stripping mechanism 12 is arranged at the other end of the fixed rod 11, that is, the left end.

[0018] The aforementioned first edge stripping mechanism 11 includes a first adjustment seat 111, a second adjustment seat 112 and a first edge stripping semicircle roller 113, the first adjustment seat 111 is fixed with the fixing rod 1 by the first screw 1111, and the second adjustment seat 111 is fixed by the first screw 1111. The adjustment seat 112 is fixed by the second screw 1121 and the fixed rod 1, and one end (right...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com