Wire wheel unwinding frame

A technology of wire frame and wire wheel, which is applied in the field of power line winding equipment, can solve the problems of affecting production efficiency and winding quality reliability, difficult to control the winding force, and unable to wind the wire bag, etc., so as to save labor costs, The effect of simple structure and reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

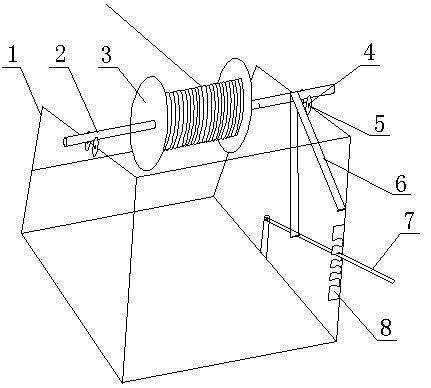

[0011] Such as figure 1 As shown, the reel pay-off frame of the present invention includes a bracket 1 and a rotating shaft 2 for threading the reel 3, and the rotating shaft 2 and the reel 3 should be closely matched to ensure that the two rotate synchronously. The top of the support 1 is provided with a support limit mechanism, which has 2 supporting rollers 4, the support rollers 4 are connected with the support 1 through the mandrel 5, and the support rollers 4 can rotate freely for supporting shaft 2, and prevent shaft 2 from moving radially. The lower part of the bracket 1 is provided with a tension brake device, which includes a positioning support plate 8, an operating rod 7 and a flexible friction belt 6, and the positioning support plate 8 is fixedly connected with the support 1, and the positioning One or more positioning slots are provided on the support plate 8 for the state positioning of the operating rod 7 during the tensioning operation. One end of the opera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com