All-cotton anti-pilling super-soft sanded fabric preparation method and device

A preparation device and anti-pilling technology, applied in the field of fabric production, can solve the problems of long dyeing time, poor drying time, poor dyeing effect of brushed fabrics, etc., and achieve the effect of improving convenience and dyeing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

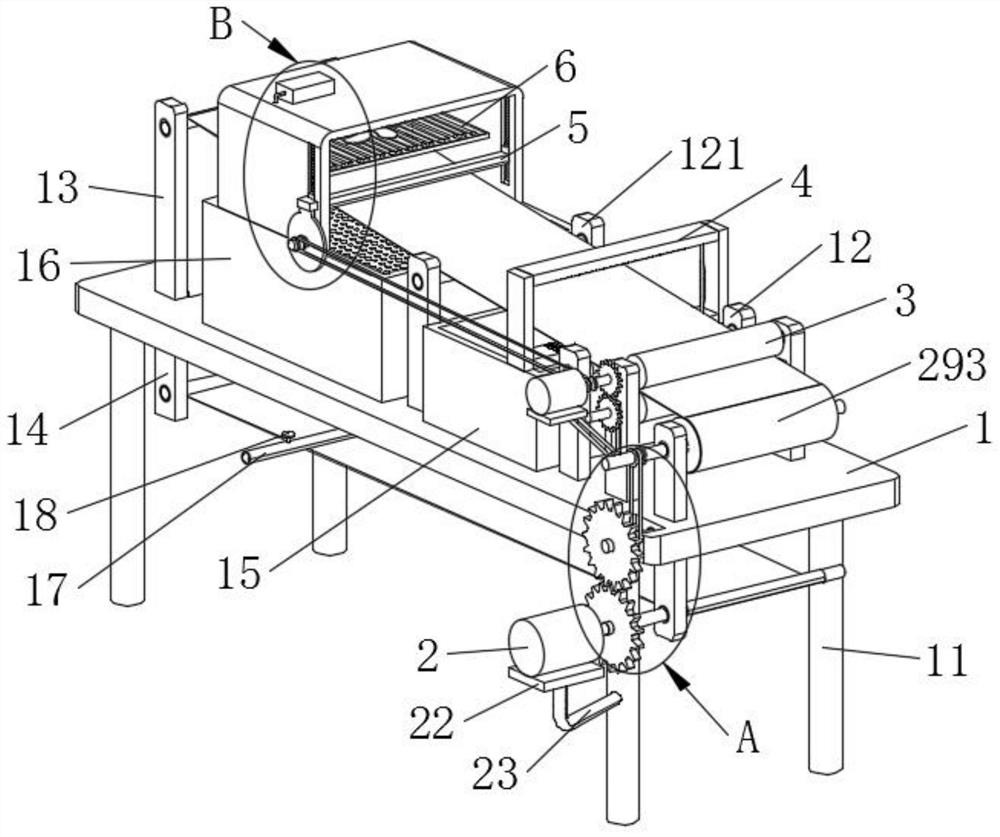

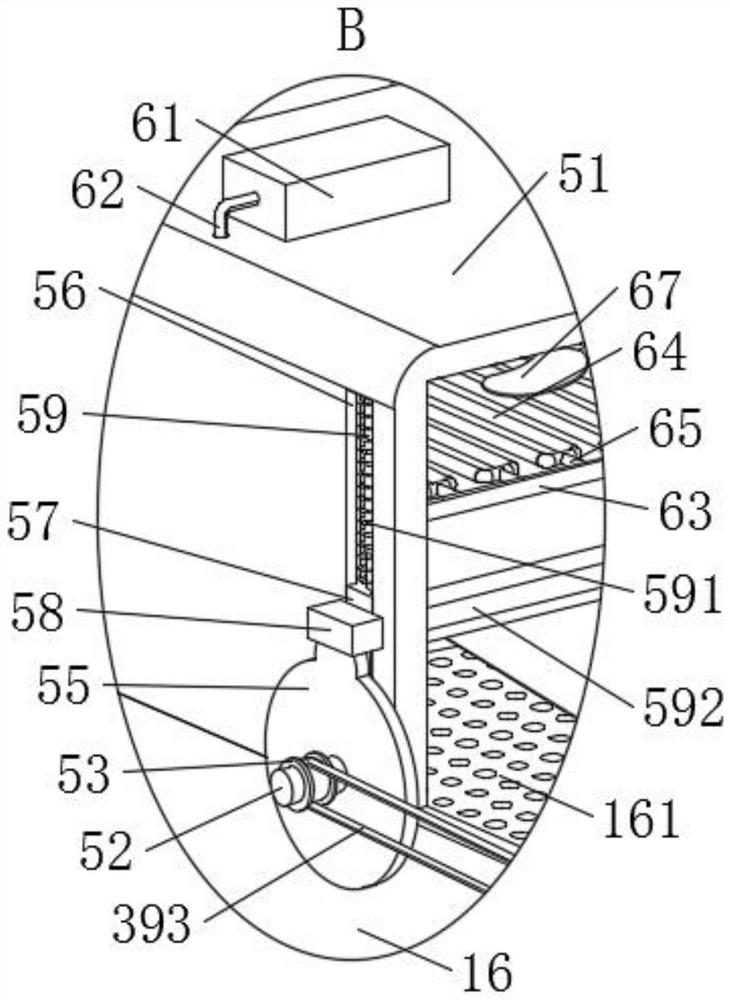

[0049] see Figure 1-11 , the present invention provides a technical solution: a method for preparing an all-cotton anti-pilling supersoft brushed fabric, comprising the following steps:

[0050] Step 1. Winding, making the original yarn into a larger bobbin, and checking the yarn to remove yarn defects;

[0051] Step 2, warp processing;

[0052] S1, warping, winding the specified number of warp yarns on the warp beam in parallel and evenly according to the specified length;

[0053] S2, sizing, the warp yarns after sizing and warping or the warp yarns after dyeing are hung on the creel of the sizing machine;

[0054] S3, drawing in healds, pulp raw yarn passes through three accessories such as menacea, healds and reeds to facilitate weaving warp menaces;

[0055] S4, the healds, cooperate with the peach plate of the loom, and carry out heald lifting;

[0056] S5, steel reed, cooperate with the input and heald lifting of weft yarn;

[0057] S6, on the machine, the shaft y...

Embodiment approach

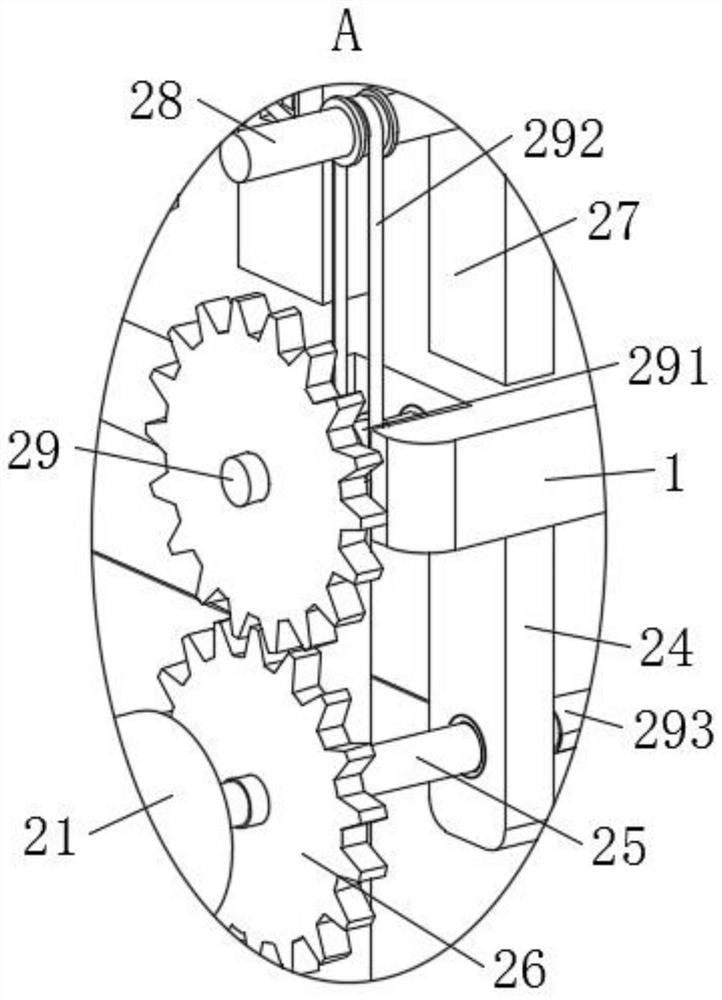

[0064] As an embodiment of the present invention, the winding mechanism 2 includes a first motor 21, the outer wall of the first motor 21 is fixedly connected with a first fixed block 22, and the first fixed block 22 can effectively improve the stability of the first motor 21. The first support rod 23 is fixedly installed on the lower surface of the first fixed block 22, and one end of the first support rod 23 is fixedly connected with the outer wall of the support leg 11, and the first support rod 23 can support and fix the first fixed block 22; preparation The lower surface of the table 1 is symmetrically and fixedly installed with first vertical plates 24, and a winding roller 25 is rotatably connected between two groups of first vertical plates 24, and the drive output end of the first motor 21 is fixedly connected with one end of the winding roller 25, By turning on the first motor 21, the drive shaft of the first motor 21 can drive the winding roller 25 to rotate, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com