Flat dehydration device

A dehydration device and leveling technology, which is applied in the directions of vibrating liquid/gas/vapor removal with textile materials and liquid/gas/vapor removal by air jet method, which can solve different leveling effects, inability to remove wrinkles, increase equipment cost and production process and other problems to achieve the effect of preventing deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to enable those skilled in the art to better understand the solution of the present invention, the invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

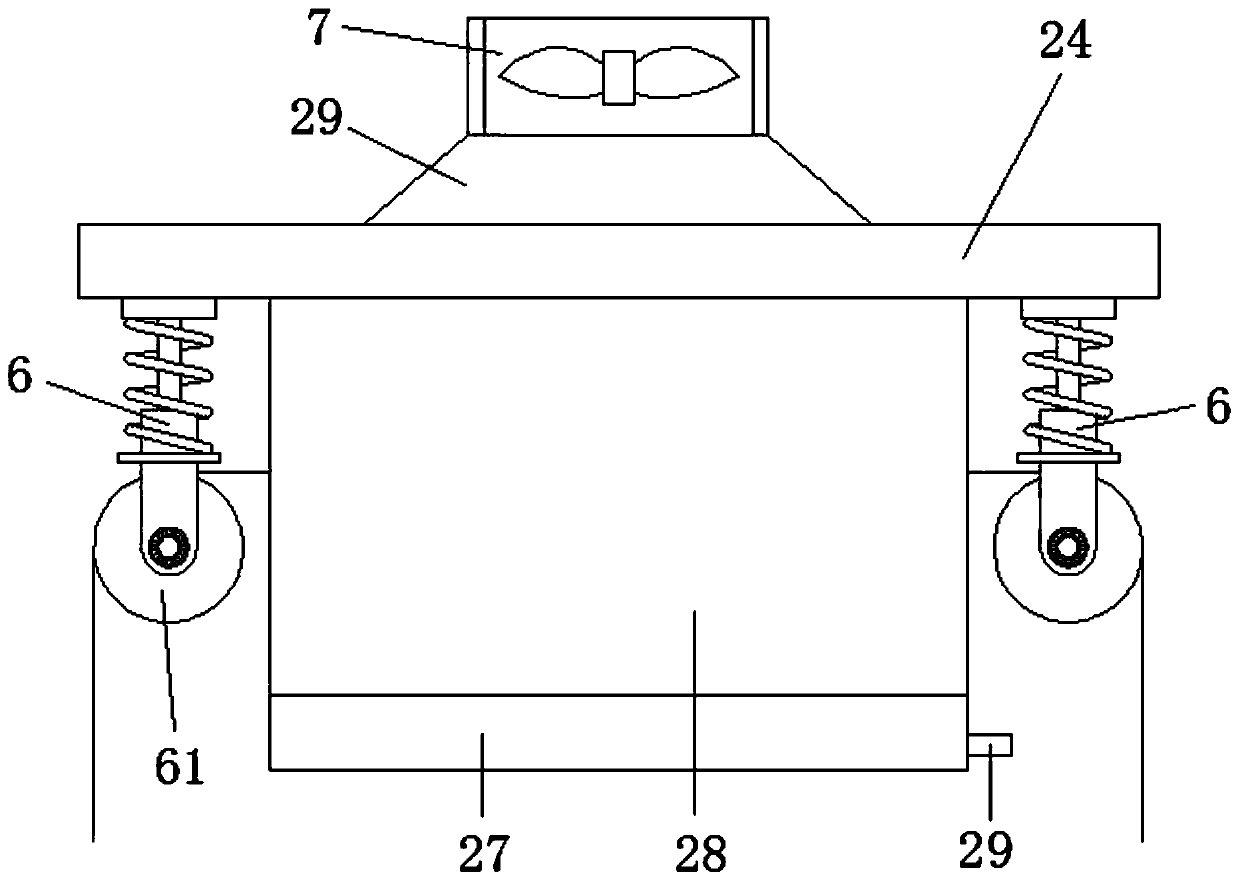

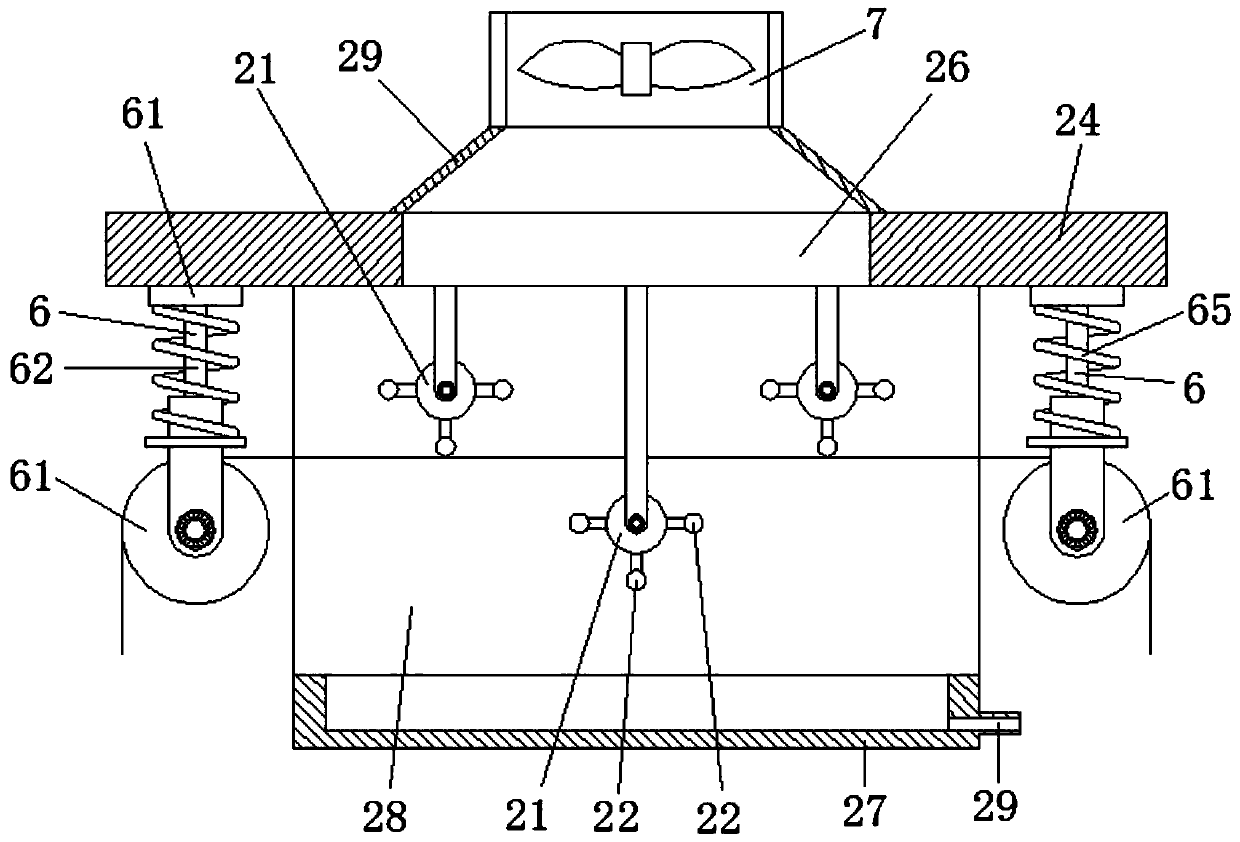

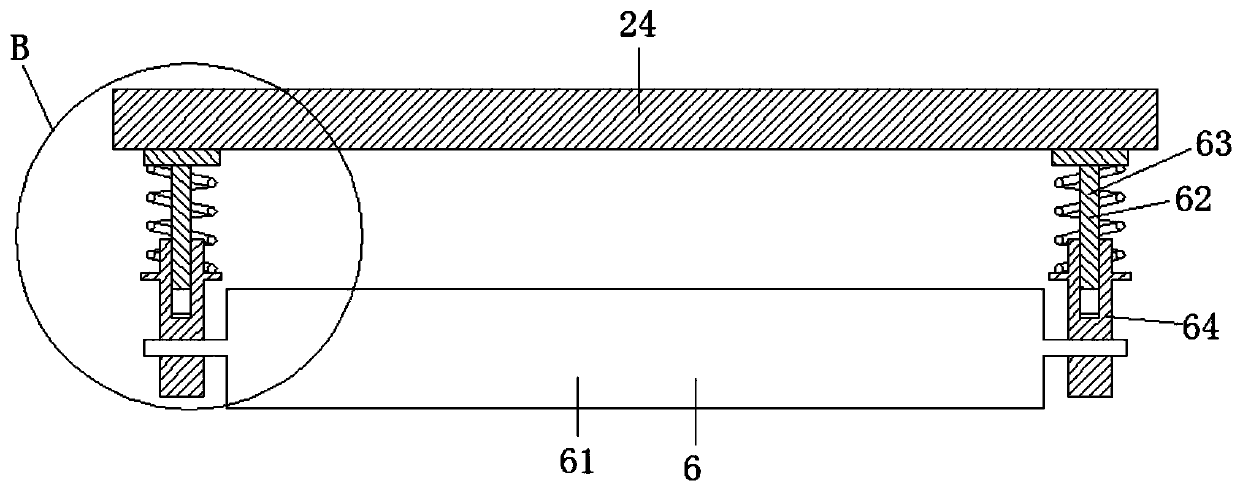

[0018] like Figure 1-5 A flattening and dehydrating device shown includes a top plate 24, a fan 7 arranged on the top plate 24, and a beating roller 21 arranged below the top plate 24. The beating rollers 21 are arranged at intervals up and down along the passage of the fabric, and the fan 7 is located at The fabric passes above the path and is blown downward, and the beating roller 21 is surrounded by a beating bar 22, and the beating bar 22 rotates with the beating roller 21 to beat and dehydrate the fabric. As a preferred solution, the blower fan 7 blows downwards through the air outlet 26 on the top plate 24, and a draft cover 29 is installed on the fan 7. Air volume.

[0019] The beating roller 21 includes a main roller 20 and a beating bar ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com