Textile printing and dyeing dewatering device adopting gravity self-deviation correcting

A technology of textile printing, dyeing, and dehydration device, which is applied in the directions of vibrating liquid/gas/vapor removal of textile materials and removing liquid/gas/vapor by squeezing rollers, which can solve uneven stress, chromatic aberration, and small extrusion force and other problems to achieve the effect of improving quality, avoiding chromatic aberration, and improving processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

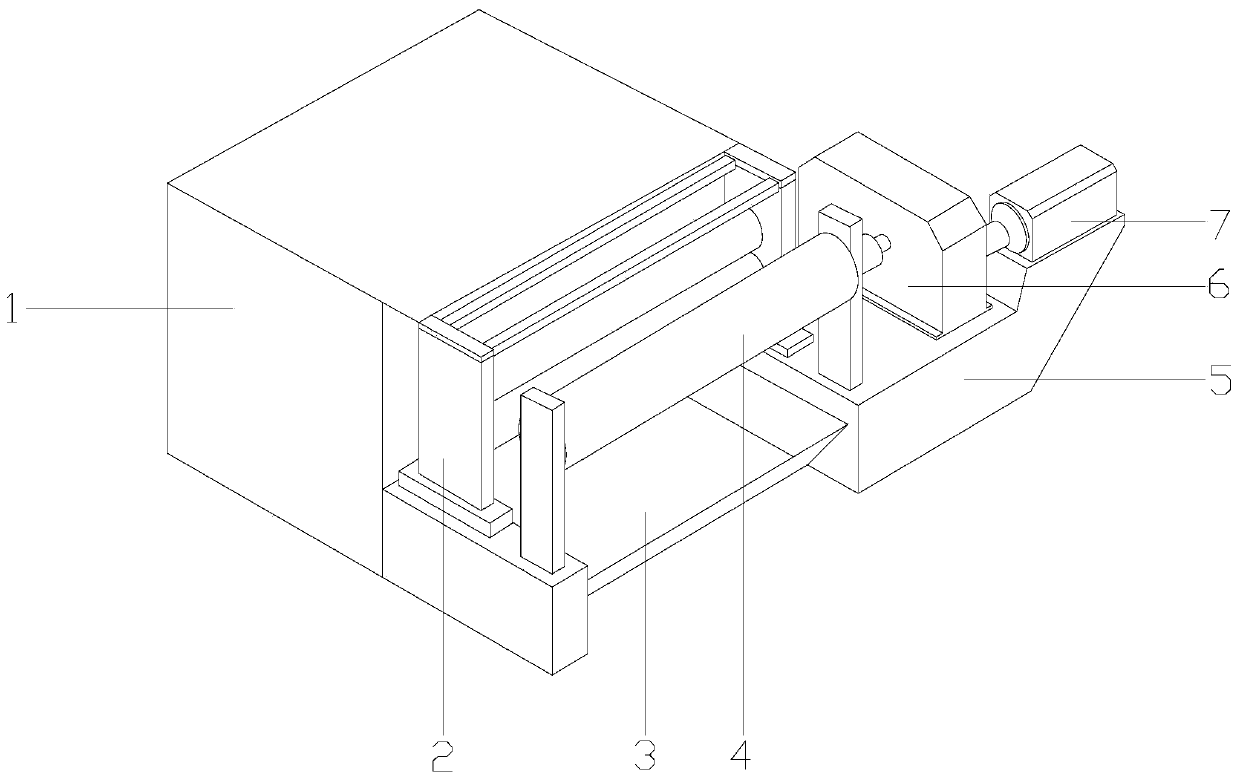

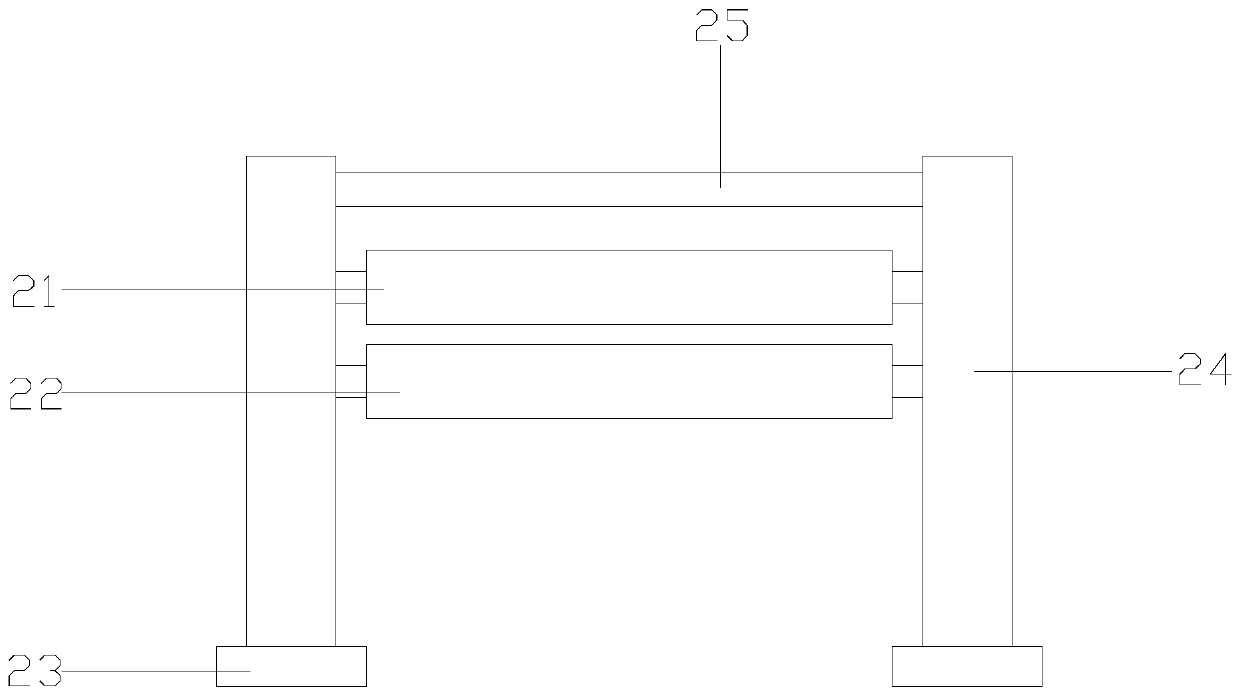

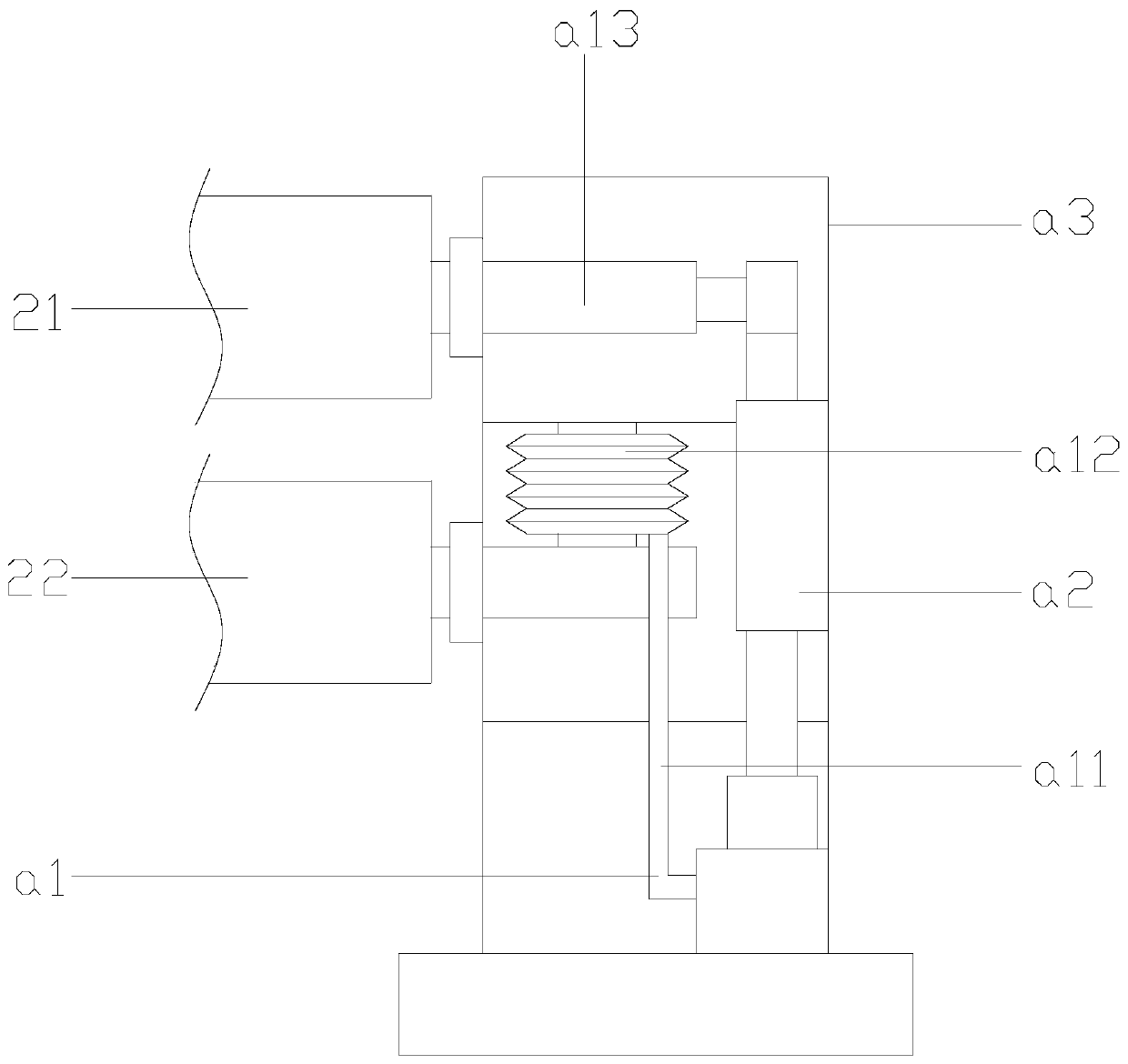

[0025] see Figure 1-Figure 2 , the present invention provides a textile printing and dyeing dehydration device adopting gravity self-correction, its structure includes printing and dyeing machine main body 1, extrusion dehydration structure 2, waste liquid collection tank 3, traction wheel 4, driving device fixing seat 5, gearbox 6, Drive motor 7, the main body 1 of the printing and dyeing machine is installed horizontally on the ground of the textile workshop, the back of the extrusion dehydration structure 2 is close to the front of the main body 1 of the printing and dyeing machine, and the traction wheel 4 is located in front of the extrusion dehydration structure 2 And parallel to the extrusion dehydration structure 2, the waste liquid collection tank 3 is a hollow trapezoidal structure and the top is welded together with the bottom surface of the main body 1 of the printing and dyeing machine, the fixing seat 5 of the driving device is located on the right side of the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com