Dyeing machine for low-gram weight high-strength polyester fiber fabric

A polyester fiber, high-strength technology, applied in the treatment of textile materials, the removal of liquid/gas/steam by vibration of textile materials, textile processing machine accessories, etc., can solve the problems affecting the quality of cloth dyeing, to improve the dyeing effect, Avoid damage and improve the effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

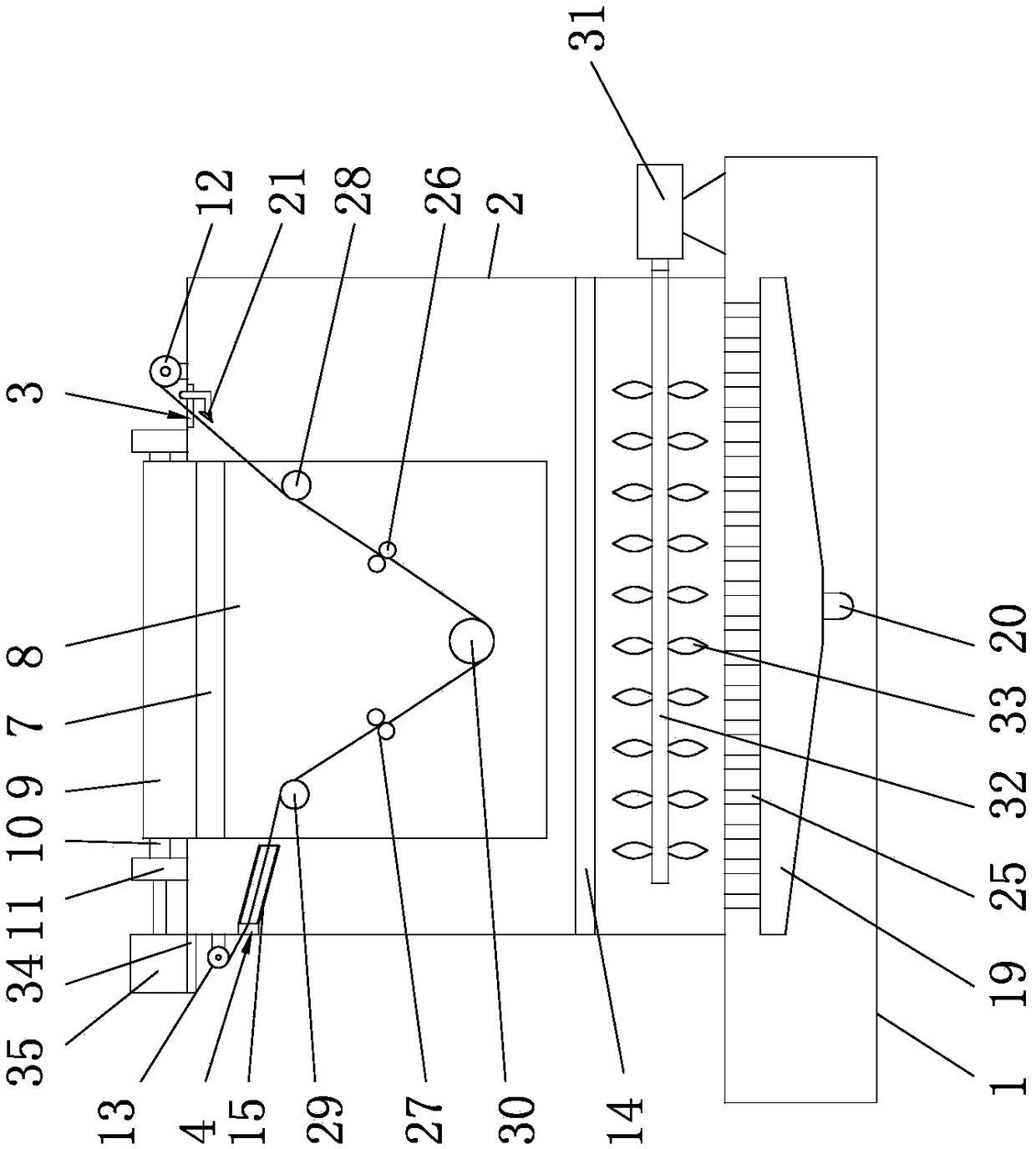

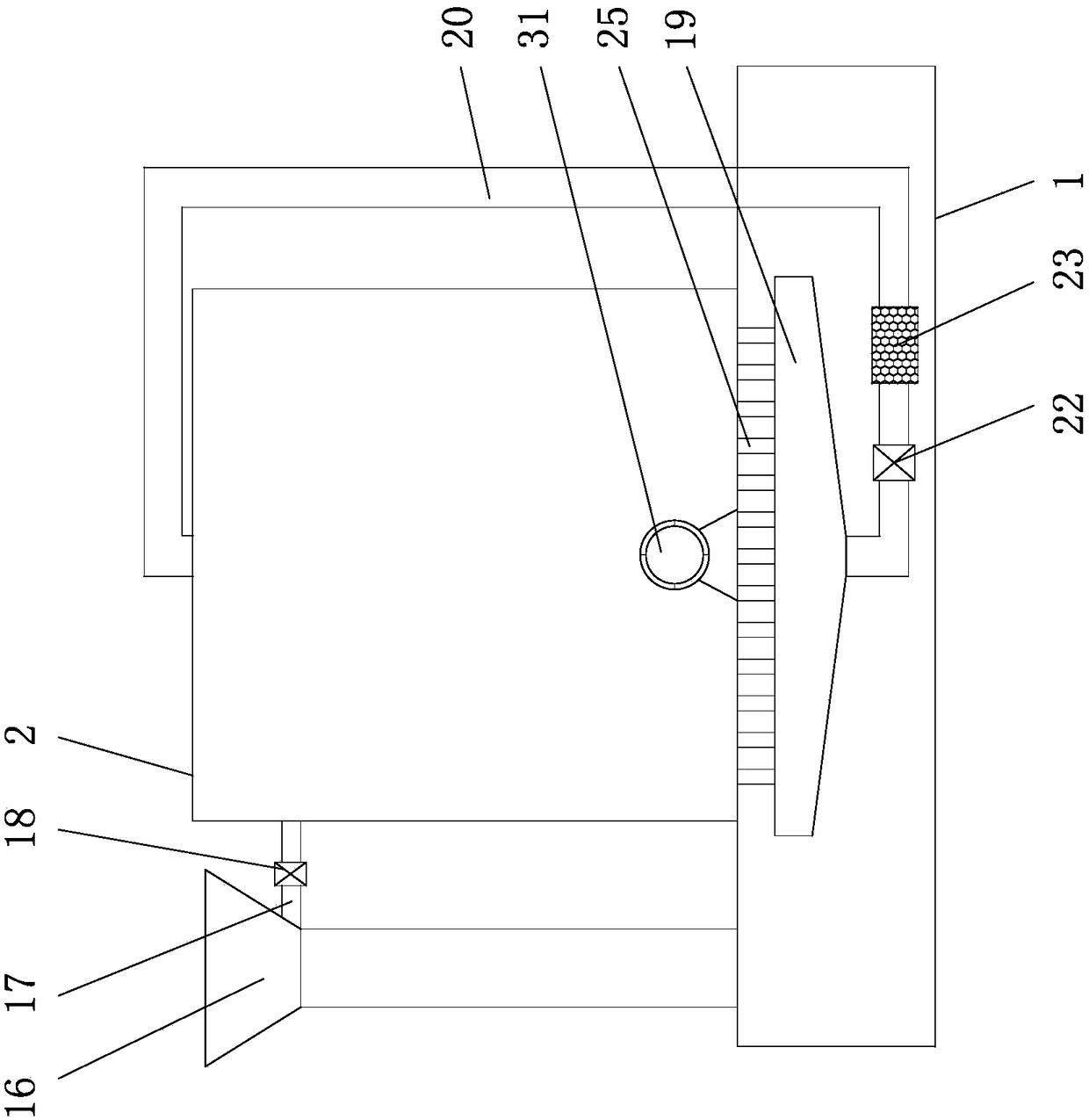

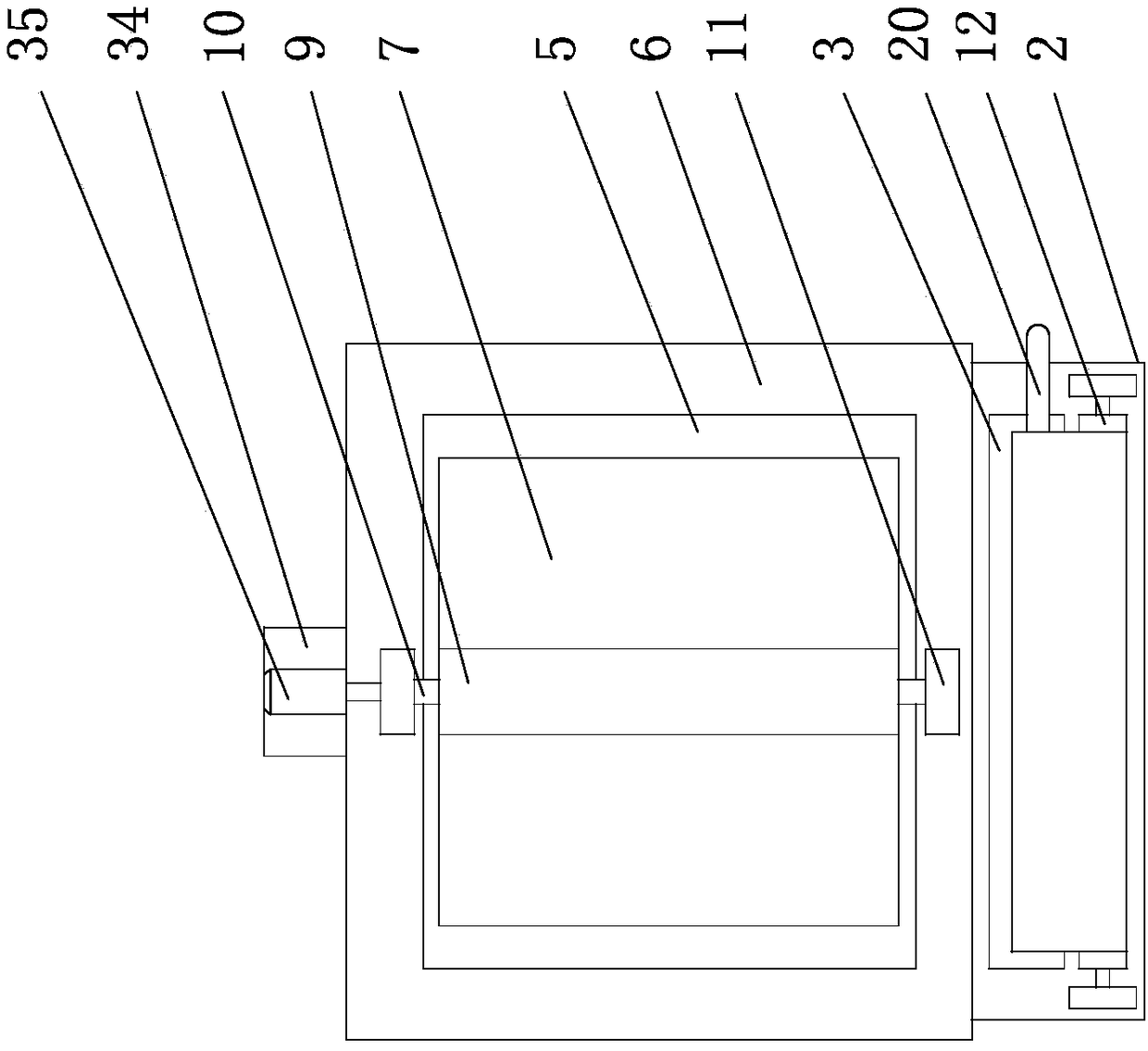

[0027] like figure 1 , figure 2 , image 3 and Figure 5 As shown, the cloth dyeing machine used for low-weight high-strength polyester fabrics includes a base 1 and a dyeing box 2, the dyeing box 2 is located on the base 1, and the dyeing box 2 has a cloth inlet 3 and a cloth outlet Port 4, the upper end of the dyeing box 2 is provided with a port 5, the edge of the port 5 is provided with a support frame 6, and the support frame 6 is provided with a cloth swing device, the cloth swing device includes a swing plate 7 and two connecting plates 8 arranged in parallel. The connecting plates 8 are respectively fixedly connected to both sides of the swing plate 7, and a clamping assembly and a guide assembly are arranged between the two connecting plates 8. The clamping assembly includes a first clamping roller 26 and a second clamping roller 27, and the guide assembly Including the first guide roller 28, the second guide roller 29 and the pressure roller 30, the cloth enters ...

Embodiment 2

[0034] like Figure 4 As shown, this embodiment is roughly the same as Embodiment 1, the difference is that the driving member is a telescopic cylinder 37, a support platform 2 36 is provided on the support frame 6 near the side of the swing plate 7, and the telescopic cylinder 37 is arranged on the support platform On the second 36, the piston rod of telescopic cylinder 37 is movably connected with its adjacent connecting plate 8 side. The telescopic cylinder 37 pushes and pulls back the connecting plate 8 to drive the swing of the first guide roller 28, the first roller holding member, the pressure roller 30, the second clamping roller member 27 and the second guide roller 29 on the connecting plate 8 to The left and right inclination of the cloth is realized, wherein the swing plate 7, the connecting block 9, the connecting shaft 10 and the support seat 11 are used to cooperate with the swing of the connecting plate 8.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com