Preparation method and equipment of regenerated fiber

A technology of regenerated fiber and equipment, which is applied in the field of regenerated fiber preparation, can solve the problems of poor working efficiency of equipment and waste of resources, and achieve the effects of saving drying time, cost and increasing residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

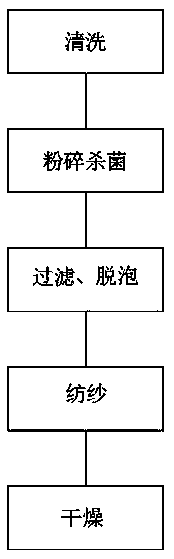

[0032] Such as Figure 1-5 Shown, a kind of preparation method of regenerated fiber comprises the following steps:

[0033] ① Collect waste fibers and cotton linters;

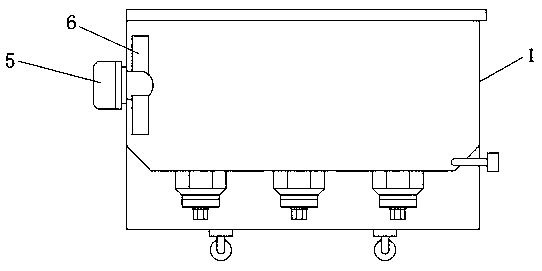

[0034] ② Cleaning work, put the waste fiber into the ultrasonic cleaning machine 1 for cleaning and decontamination, and the cleaning time is 1h; while the ultrasonic cleaning machine 1 cleans the waste fiber, the motor 1 5 drives the stirring paddle 6 to rotate, so that a vortex is formed inside the cleaning machine, Effective cleaning of waste fibers;

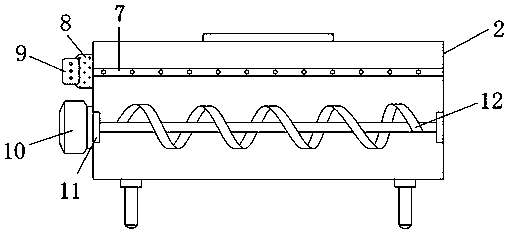

[0035] ③ Grinding and sterilizing device, place the cleaned waste fiber and cotton linters in the pulverizing and sterilizing machine 2 for crushing, sterilizing and acidifying. The acidifying work uses an acidifying agent, and the acidifying time is 90 minutes; both waste fibers and cotton linters are crushed The sterilizer 2 carries out crushing and sterilizing, etc. Waste fibers and cotton linters enter the crushing sterilizer 2, start the motor 210 to wo...

Embodiment 2

[0040] Such as Figure 1-5 Shown, a kind of preparation method of regenerated fiber comprises the following steps:

[0041] ① Collect waste fibers and cotton linters;

[0042] ② Cleaning work, put the waste fiber into the ultrasonic cleaning machine 1 for cleaning and decontamination, and the cleaning time is 1.5h; while the ultrasonic cleaning machine 1 cleans the waste fiber, the motor 1 5 drives the stirring paddle 6 to rotate, so that a vortex is formed inside the cleaning machine , effectively clean the waste fibers;

[0043] ③ Grinding and sterilizing device, place the cleaned waste fibers and cotton linters in the pulverizing and sterilizing machine 2 for crushing, sterilizing and acidifying. The acidifying work uses an acidifying agent, and the acidizing time is 115 minutes; both waste fibers and cotton linters are crushed The sterilizer 2 carries out crushing and sterilizing, etc. Waste fibers and cotton linters enter the crushing sterilizer 2, start the motor 210 t...

Embodiment 3

[0048] Such as Figure 1-5 Shown, a kind of preparation method of regenerated fiber comprises the following steps:

[0049] ① Collect waste fibers and cotton linters;

[0050] ② Cleaning work, put the waste fiber into the ultrasonic cleaning machine 1 for cleaning and decontamination, and the cleaning time is 2 hours; while the ultrasonic cleaning machine 1 cleans the waste fiber, the motor 1 5 drives the stirring paddle 6 to rotate, so that a vortex is formed inside the cleaning machine, Effective cleaning of waste fibers;

[0051] ③ Grinding and sterilizing device, place the cleaned waste fibers and cotton linters in the pulverizing and sterilizing machine 2 for crushing, sterilizing and acidizing. The acidifying work uses an acidifying agent, and the acidizing time is 120 minutes; both waste fibers and cotton linters are crushed The sterilizer 2 carries out crushing and sterilizing, etc. Waste fibers and cotton linters enter the crushing sterilizer 2, start the motor 210 to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com