Residual coating cleaner

A technology of remover and coating, applied in the direction of vibrating liquid/gas/steam removal with textile materials, which can solve problems such as product coating breakage, textile product quality degradation, tearing cloth, etc., and achieve a good yield effect

Inactive Publication Date: 2013-03-27

SUZHOU DANFANG TEXTILE R & D

View PDF4 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] At present, during the printing and dyeing process of many fiber production and textile production, the product must be immersed in the coating pool for pre-soaking to reduce the difficulty of processing and improve the performance and quality of the product. The surface of the pre-soaked product often accumulates more coatings , the traditional way is to use a scraper or a pressure roller to remove, but these measures often cause the coating of the product to break or tear the cloth, resulting in a decline in the quality of the textile product and affecting the yield of the product

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

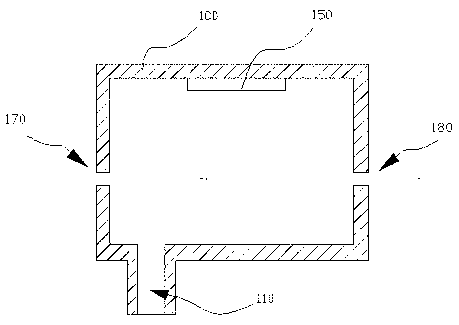

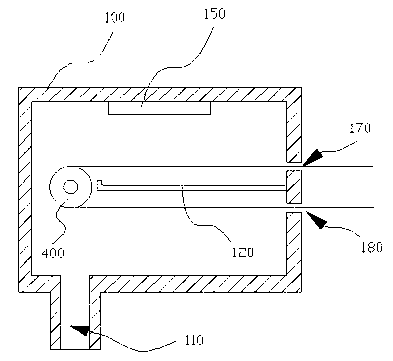

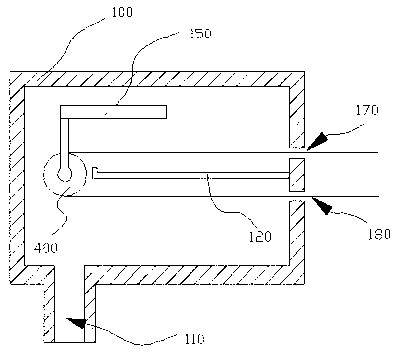

The invention discloses a residual coating cleaner. The residual coating cleaner comprises a coating cleaning chamber, wherein the coating cleaning chamber comprises a cloth inlet and a cloth outlet; at least one loudspeaker is arranged in the coating cleaning chamber; a waterproof coating covers a vibrating diaphragm of the loudspeaker; the loudspeaker is electrically connected with a power amplifier circuit; a guide path is formed in the coating cleaning chamber; and the guide path reaches to a coating pond. The residual coating cleaner can be used for cleaning the residual coating on the cloth by enabling the cloth to not contact any appliance, so that the cloth has a high yield.

Description

technical field [0001] The invention relates to the field of textile machines, in particular to a textile machine for removing redundant coatings on textiles. Background technique [0002] At present, during the printing and dyeing process of many fiber production and textile production, the product must be immersed in the coating pool for pre-soaking to reduce the difficulty of processing and improve the performance and quality of the product. The surface of the pre-soaked product often accumulates more coatings , the traditional method is to use a scraper or a pressure roller to remove, but these measures often cause the coating of the product to break or tear the cloth, resulting in a decline in the quality of the textile product and affecting the yield of the product. Contents of the invention In order to solve the above problems, the object of the present invention is to provide a residual coating remover, which can well remove redundant coatings on the surface of t...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): D06B15/06

Inventor 林秀云

Owner SUZHOU DANFANG TEXTILE R & D

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com