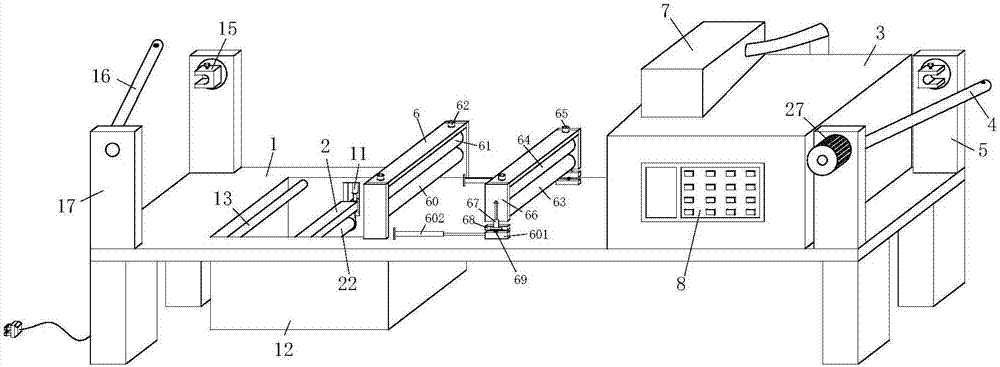

Textile fabric cleaning and drying integrated device

A textile fabric and drying technology, applied in the textile field, can solve the problems of affecting sales, high energy consumption, unfavorable use, etc., and achieve the effects of fast drying, reducing production costs, and increasing flow speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

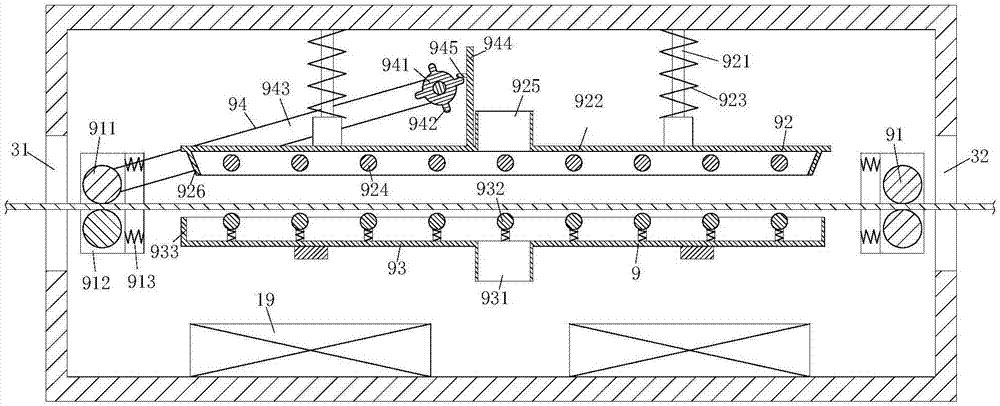

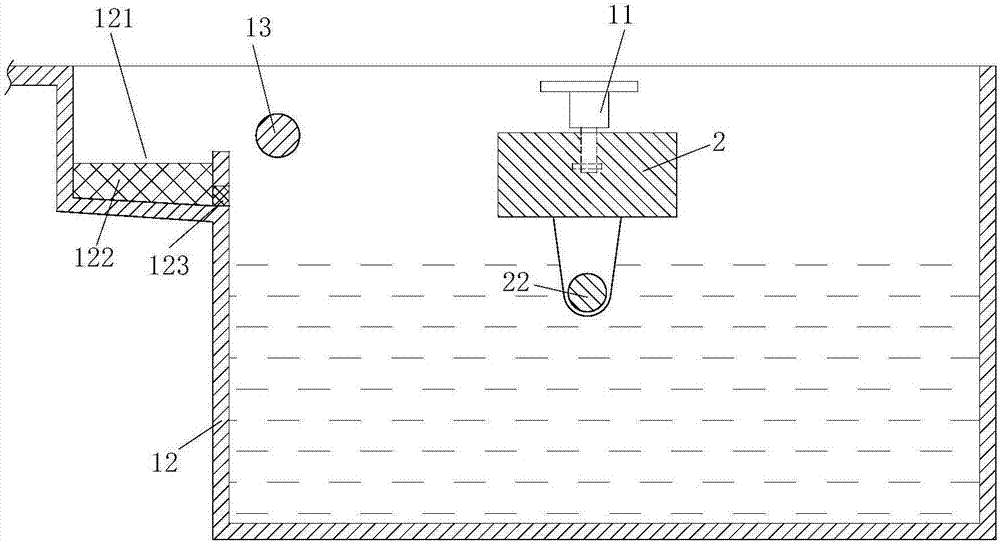

[0024]As an embodiment of the present invention, the shaking unit 6 includes a fixed module and a mobile module, the fixed module is fixed at the rear of the water tank 12, the fixed module is used to clamp one end of the textile cloth, and the fixed module includes a first fixed roller 60, The first squeeze roller 61, the first pressure regulator 62 and the first drive motor, the first fixed roller 60 is non-rotatably fixed on the top of the workbench 1 through the bracket, and the first squeeze roller 61 is installed on the Just above a fixed roller 60, the first pressure regulator 62 can adjust the vertical distance between the first squeeze roller 61 and the first fixed roller 60, which can adapt to the clamping of textile cloths of different thicknesses; The motor is used to drive the first extrusion roller 61 to rotate; the mobile module is positioned at the rear of the fixed module, and the mobile module is used to clamp the other end of the textile cloth and cooperate w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com