Textile fabric desizing device

A desizing device and a technology for textile fabrics, which are applied in the direction of textile material equipment configuration, textile material treatment, spray/spray textile material treatment, etc. Solve problems such as slurry residue, achieve fast, efficient and uniform desizing effect, and improve cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

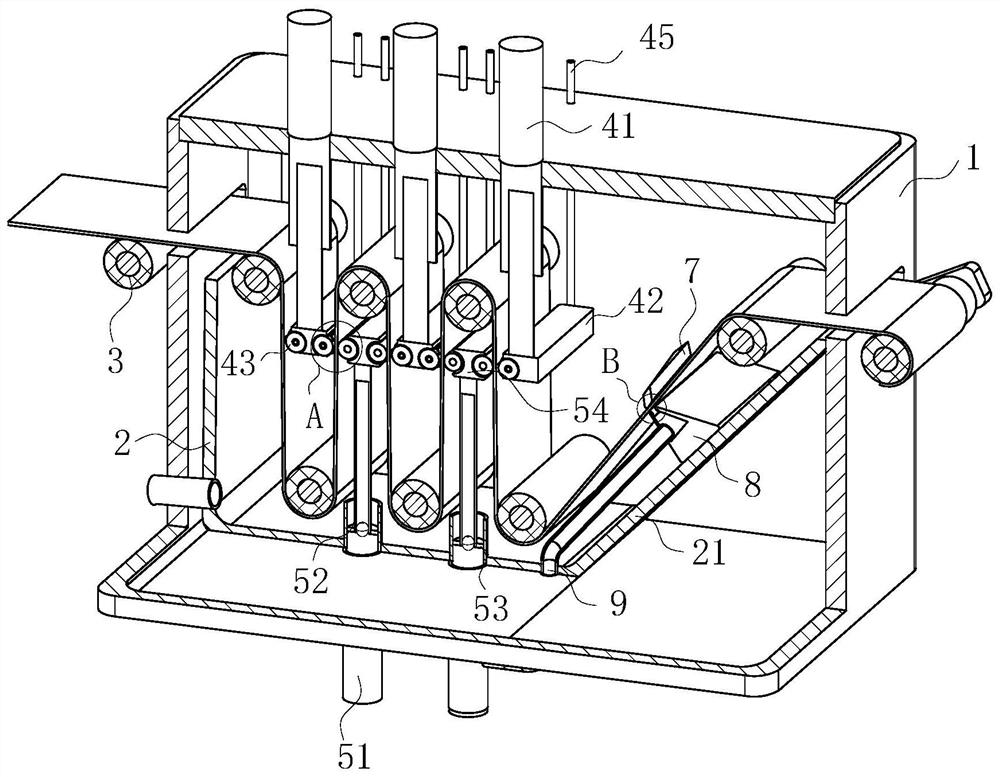

[0028] As an embodiment of the present invention, one side of the immersion tank 2 is provided with an inclined plate 21, and the upper end surface of the inclined plate 21 is obliquely provided with a scraper 6; Sliding contact with the side wall of the scraper; the symmetrical position of the scraper 6 is provided with an oblique scraping strip 7, and the oblique scraping strip 7 is located above the fabric body; the oblique scraping strip 7 is fixed on the two side walls of the desizing pool 1; the working At this time, when the fabric body after desizing is transported to the top of the inclined plate 21 on one side of the water immersion tank 2 by the guide roller 3, the scraper 6 provided on the inclined plate 21 can scrape the dissolved product adhered on the fabric body. After being scraped off by the scraper 6, the dissolved product will fall into the water immersion tank 2 through the inclined plate 21. At the same time, the oblique scraper 7 arranged symmetrically wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com