Textile fabric dewatering device

A dewatering device and a technology for textile fabrics, which are applied in the processing of textile materials, textiles and papermaking, textile processing machine accessories, etc., can solve the problems of inconvenient processing, troublesome fabric finishing and smoothing, etc., and achieve the effect of improving the opening effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

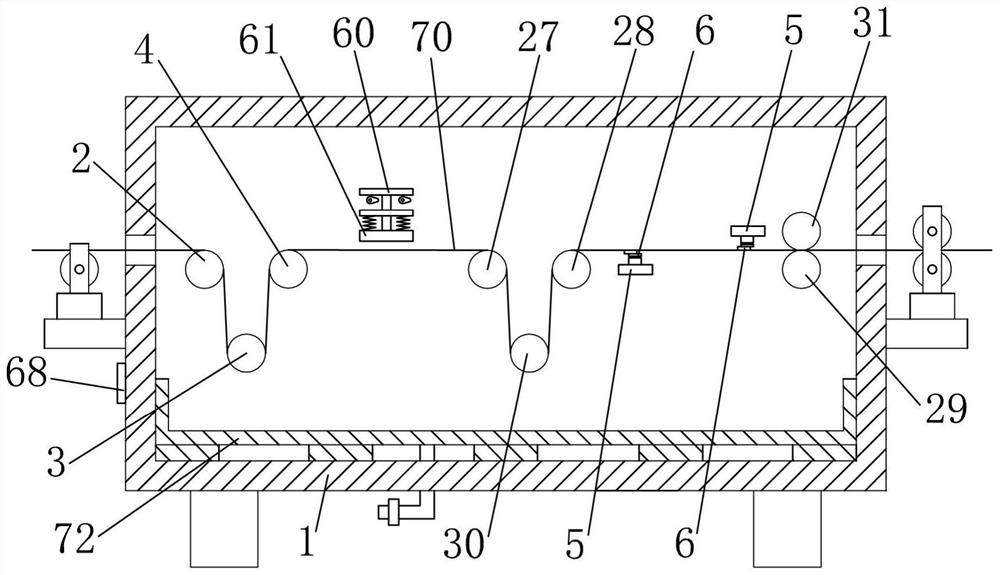

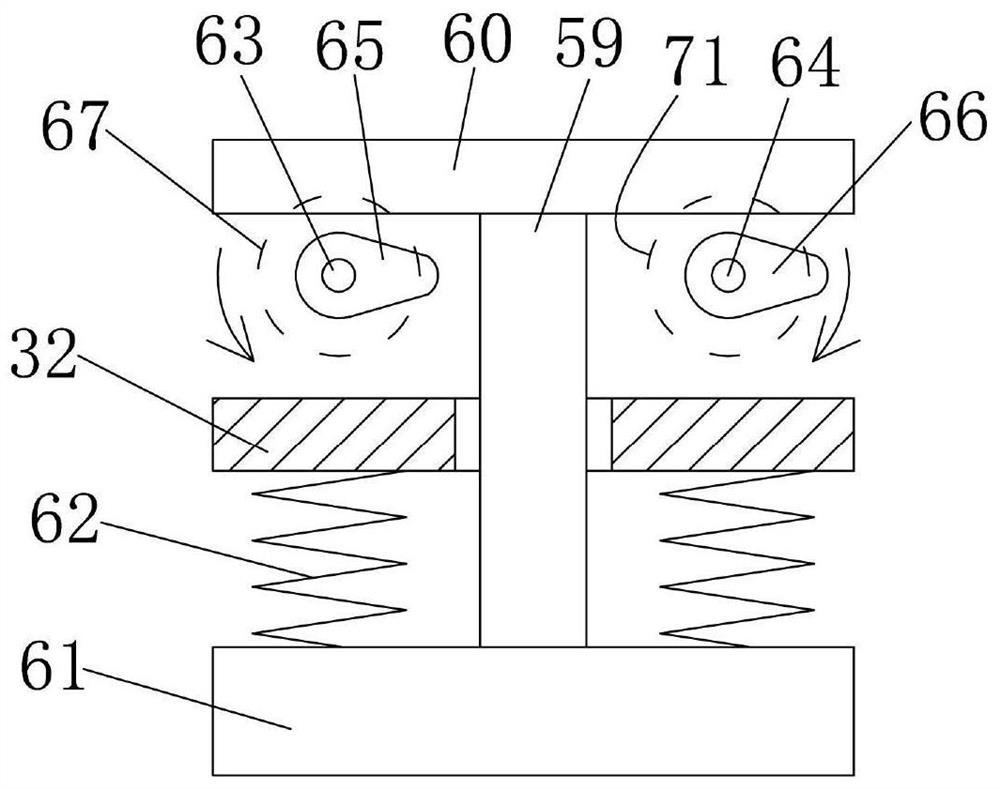

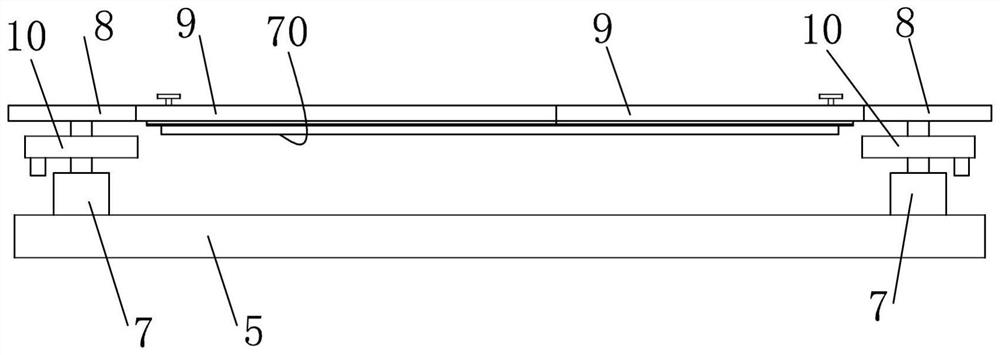

[0024] Embodiment: a kind of textile cloth dehydration device, as Figure 1-Figure 8As shown, a box body 1 is included, and the first conveying roller 2, the first tension roller 3, the second conveying roller 4, the third conveying roller 27, the second sheet Tight roller 30, the 4th conveying roller 28 and the 5th conveying roller 29, described first conveying roller 2, the 2nd conveying roller 4, the 3rd conveying roller 27, the 4th conveying roller 28 and the 5th conveying roller 29 are used for cloth 70 transmission, the first tension roller 3 and the second tension roller 30 are used to adjust the tension of the cloth 70, a support plate 32 is provided between the second transmission roller 4 and the third transmission roller 27, so The two ends of the support plate 32 are respectively fixedly connected with the inner wall of the box body 1, and the support plate 32 is located above the cloth 70, and the center of the support plate 32 is provided with a moving rod 59, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com