Beating type redundant sizing material cleaning machine

A scavenger and percussive technology, applied in the field of percussive excess pulp scavenger, which can solve the problems of ineffectiveness, deterioration of product quality, and crushed fibers or fabrics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

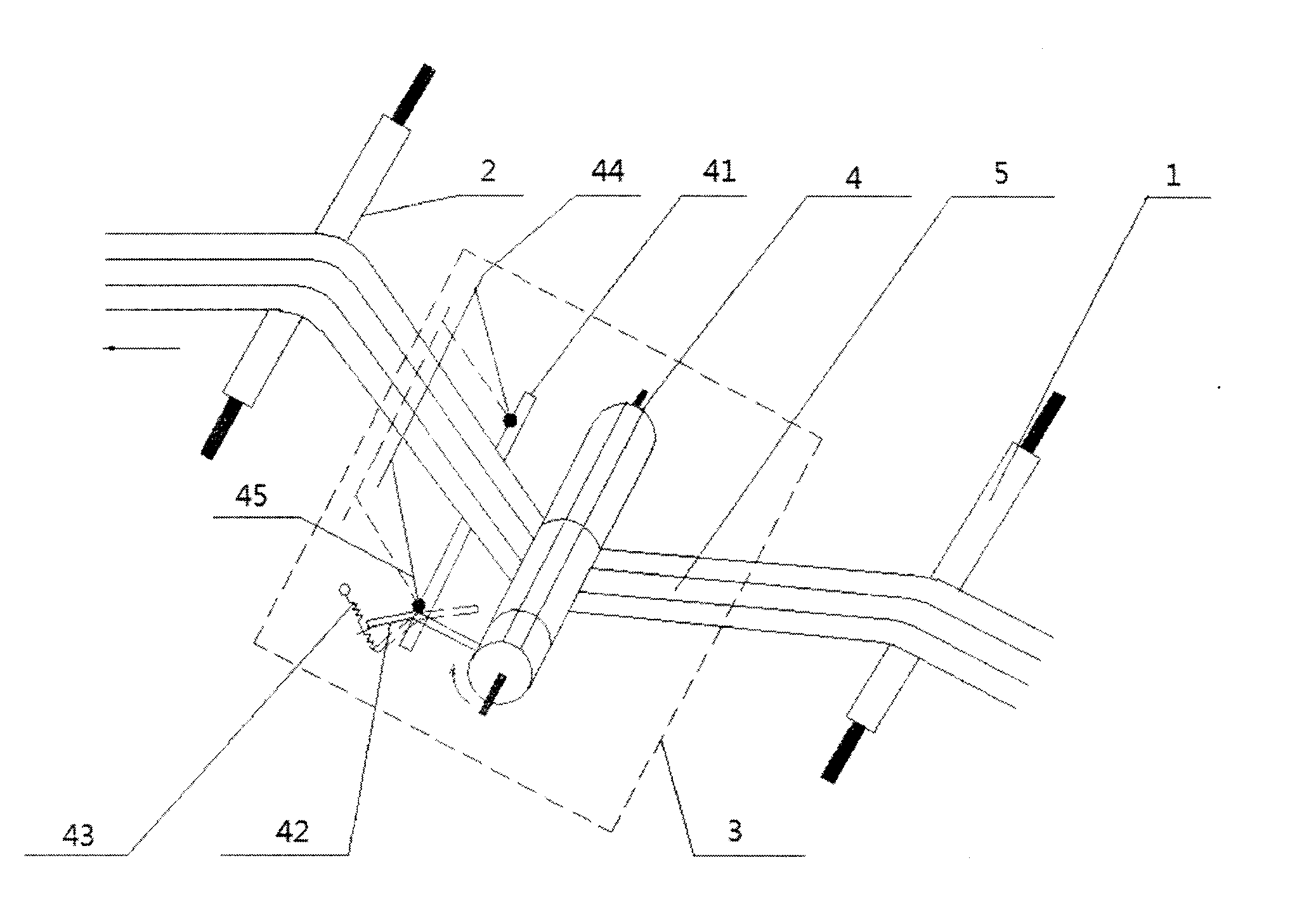

[0011] exist figure 1 In the shown embodiment, the hitting type excess slurry remover includes two first floating rollers 1 and second floating rollers 2 arranged in parallel and located above the slurry tank 3, and there is also a set between the floating rollers There is a polygonal pattern roller 4 parallel to the floating roller and placed in the slurry tank 3, the polygonal pattern roller 4 is an octagonal prism-shaped cage welded by eight slender round steels and regular octagonal support discs; fiber or The cloth 5 is passed to the second floating roller 2 through the first floating roller 1 and the polygonal pattern roller 4, and the underside between the polygonal pattern roller 4 and the second floating roller 2 is provided with a hitting shaft parallel to the polygonal pattern roller 4 41 and a beating rod 44, the beating rod 44 is fixedly connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com