A kind of epoxy resin ground construction system and technology

A technology of epoxy resin and construction technology, applied in the direction of floors, manufacturing tools, metal processing equipment, etc., can solve the problems of manual operation, time-consuming and laborious, low work efficiency, etc., achieve fast transportation, firm bonding, and improve work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

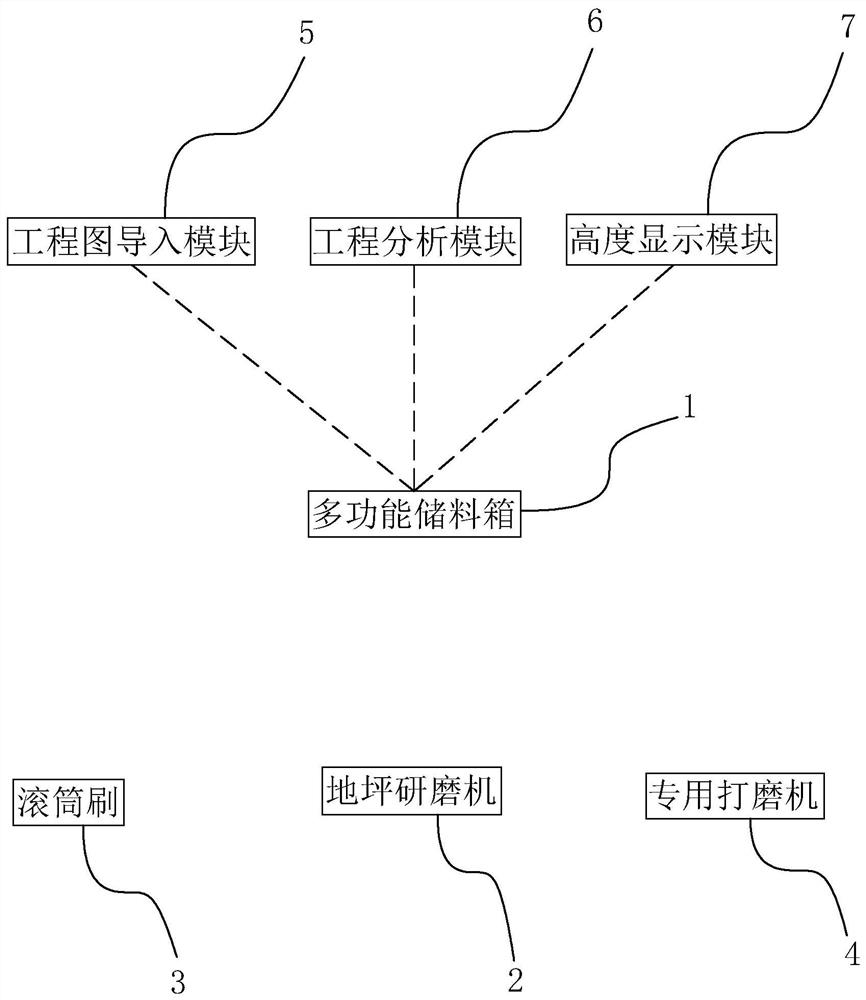

[0051] Embodiment one: a kind of epoxy resin ground construction system, such as figure 1 As shown, it includes a floor grinder 2, a roller brush 3, a special grinder 4 and a multifunctional storage box 1. The multifunctional material storage box 1 is connected with a control system, and the control system includes an engineering drawing import module 5 , an engineering analysis module 6 and a height display module 7 .

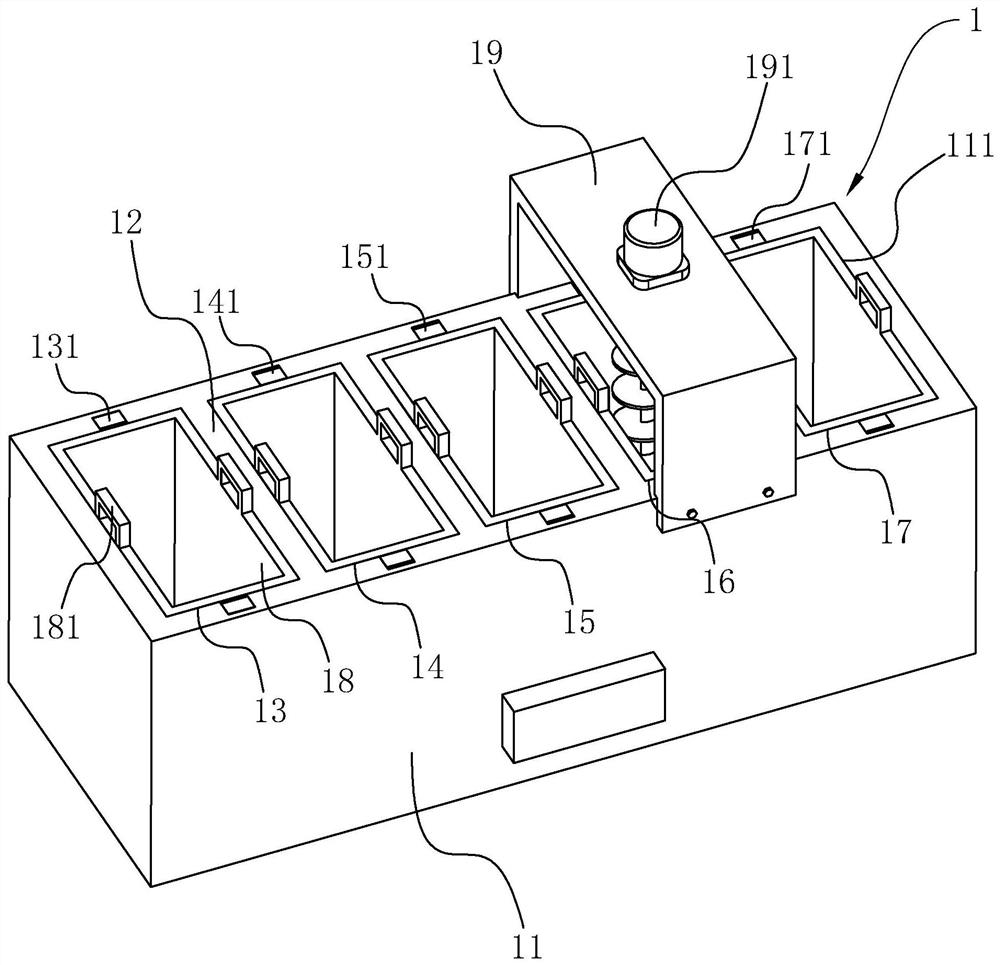

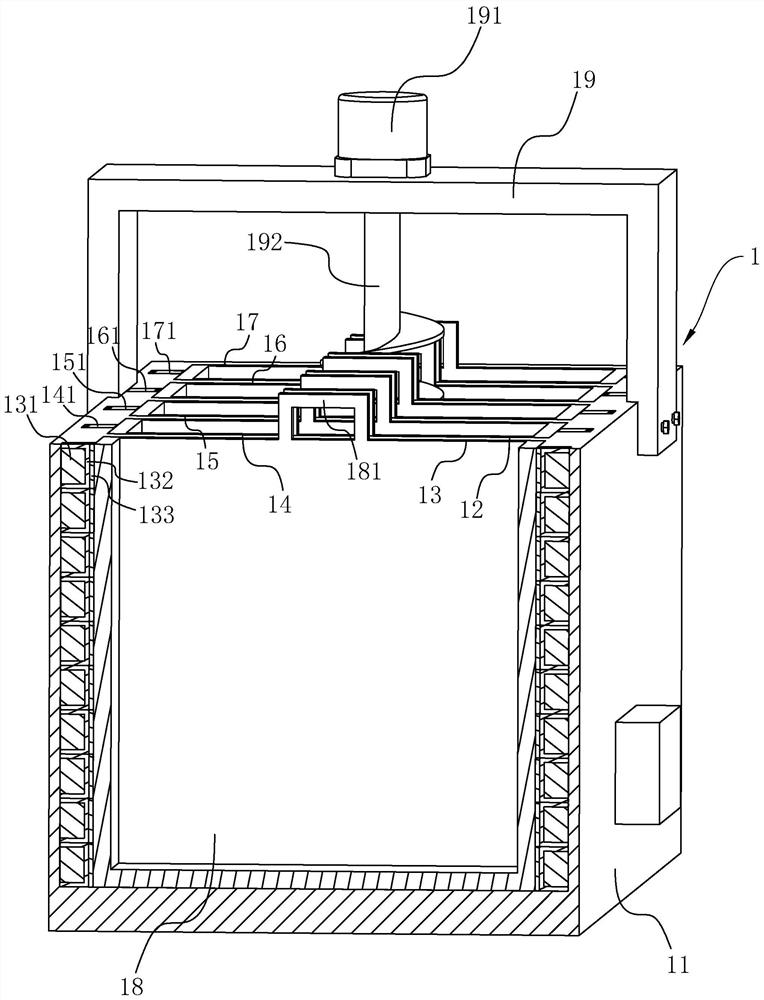

[0052] Such as figure 2 and image 3 As shown, the multi-functional material storage box 1 includes a box body 11, and a material extraction port 111 is opened on the top of the box body 11 . The box body 11 is fixed with four vertical partitions 12, and the partition boards 12 divide the inside of the box body 11 into a first storage tank 13 for receiving epoxy resin mortar, a storage tank for receiving rigid waterproof materials The second accommodating tank 14, the third accommodating tank 15 for holding the epoxy resin high penetration primer, the four...

Embodiment 2

[0058] Embodiment two: a kind of epoxy resin ground construction technique, use the epoxy resin construction system in embodiment one, concrete steps are as follows:

[0059] Step 1. Input the drawings to be constructed into the system. The system automatically calculates the required amount of materials and marks the height of materials that should be poured into the multi-functional storage box 1 through the indicator light.

[0060] Step 2: Pour corresponding materials into different storage tanks according to the division of the storage tanks of the multifunctional material storage box 1 until the materials submerge the lit indicator light. The user marks the height at which various materials need to be stored in the multifunctional storage box 1 through the indicator light, so that the user can quickly prepare materials and effectively improve work efficiency.

[0061] Step 3: Install the diamond square grinding head on the floor grinder 2, use the floor grinder 2 to proc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com