Heat-resistant and oil-resistant magnetic filter element

A heat-resistant and magnetic technology, applied in magnetic separation, engine lubrication, mechanical equipment, etc., can solve the problems that the filter element cannot effectively remove various impurities and metal dust, poor corrosion resistance, etc., achieve good oil resistance and improve filtration efficiency , High filtering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

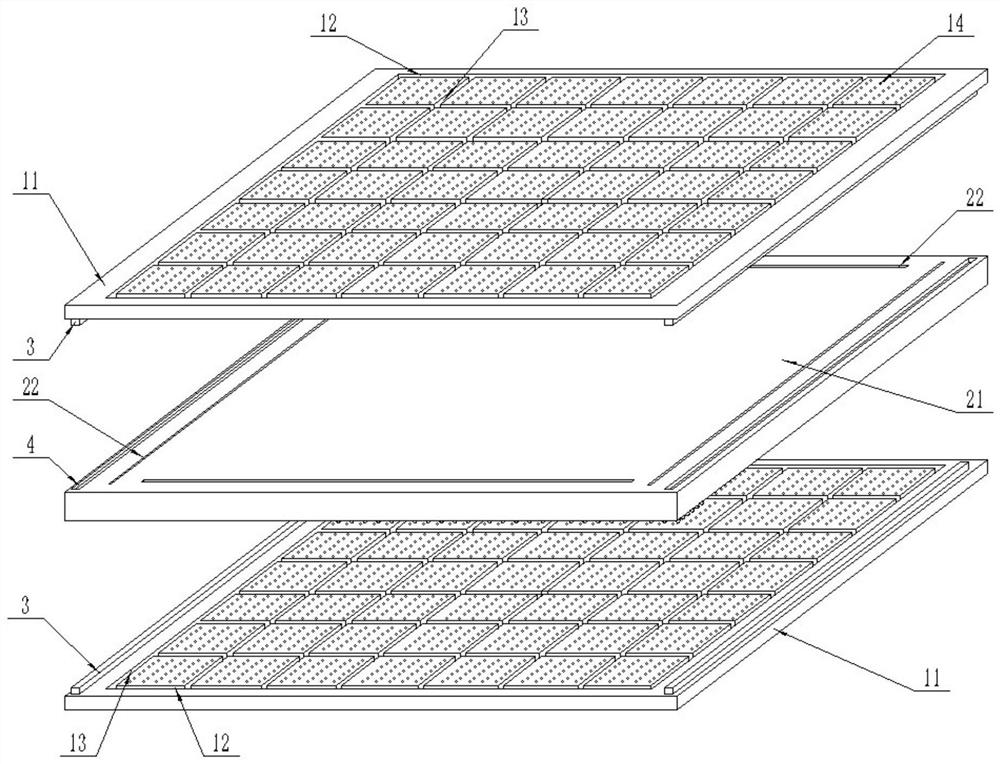

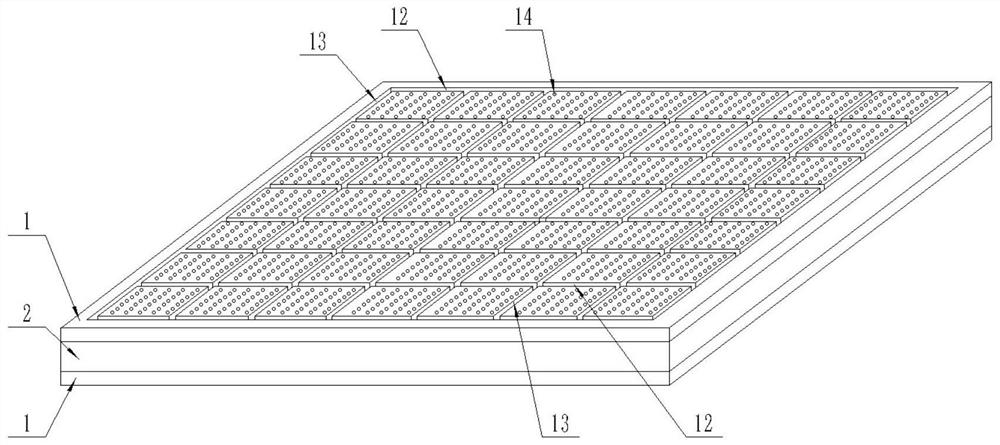

[0019] The heat-resistant and oil-resistant magnetic filter element includes two heat-resistant filter plates 1 stacked in sequence, and a magnetic filter plate 2 is sandwiched between the heat-resistant filter plates 1, and the heat-resistant filter plate 1 includes a plate body 11, The thickness of the plate one 11 is 5-20mm, and the upper surface of the plate one 11 is provided with a plurality of transverse grooves 12 and longitudinal grooves 13, and the transverse grooves 12 and the longitudinal grooves 13 are crossed. Setting, the filter area is formed between the transverse groove 12 and the longitudinal groove 13, the filter area is provided with a number of filter holes 14, the average pore diameter of the filter holes of the upper heat-resistant filter plate is 50 μm, and the lower heat-resistant filter plate The average pore diameter of the filter holes is 20 μm, and the magnetic filter plate 2 includes a plate body two 21, the thickness of the plate body two 21 is 2...

Embodiment 2

[0023] The heat-resistant and oil-resistant magnetic filter element includes two heat-resistant filter plates 1 stacked in sequence, and a magnetic filter plate 2 is sandwiched between the heat-resistant filter plates 1, and the heat-resistant filter plate 1 includes a plate body 11, The thickness of the plate one 11 is 5-20mm, and the upper surface of the plate one 11 is provided with a plurality of transverse grooves 12 and longitudinal grooves 13, and the transverse grooves 12 and the longitudinal grooves 13 are crossed. Setting, the filter area is formed between the transverse groove 12 and the longitudinal groove 13, the filter area is provided with a number of filter holes 14, the average pore diameter of the filter holes of the upper heat-resistant filter plate is 50 μm, and the lower heat-resistant filter plate The average pore diameter of the filter holes is 20 μm, and the magnetic filter plate 2 includes a plate body two 21, the thickness of the plate body two 21 is 2...

Embodiment 3

[0027] The heat-resistant and oil-resistant magnetic filter element includes two heat-resistant filter plates 1 stacked in sequence, and a magnetic filter plate 2 is sandwiched between the heat-resistant filter plates 1, and the heat-resistant filter plate 1 includes a plate body 11, The thickness of the plate one 11 is 5-20mm, and the upper surface of the plate one 11 is provided with a plurality of transverse grooves 12 and longitudinal grooves 13, and the transverse grooves 12 and the longitudinal grooves 13 are crossed. Setting, the filter area is formed between the transverse groove 12 and the longitudinal groove 13, the filter area is provided with a number of filter holes 14, the average pore diameter of the filter holes of the upper heat-resistant filter plate is 50 μm, and the lower heat-resistant filter plate The average pore diameter of the filter holes is 20 μm, and the magnetic filter plate 2 includes a plate body two 21, the thickness of the plate body two 21 is 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| oil-water separation rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com