Novel yarn dip-dyeing oiling machine

A kind of yarn, a new type of technology, applied in liquid/gas/vapor yarn/filament processing, textile and papermaking, liquid/gas/vapor removal, etc., can solve oil pollution, affect yarn quality, easy to adhere, etc. problems, to achieve the effect of improving quality and avoiding secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Compared with the traditional dip-dyeing oiling device, the present invention improves on the above-mentioned three major defects in the background technology to solve the defects in the prior art, and makes the dip-dyeing oiling machine reach a higher technical level.

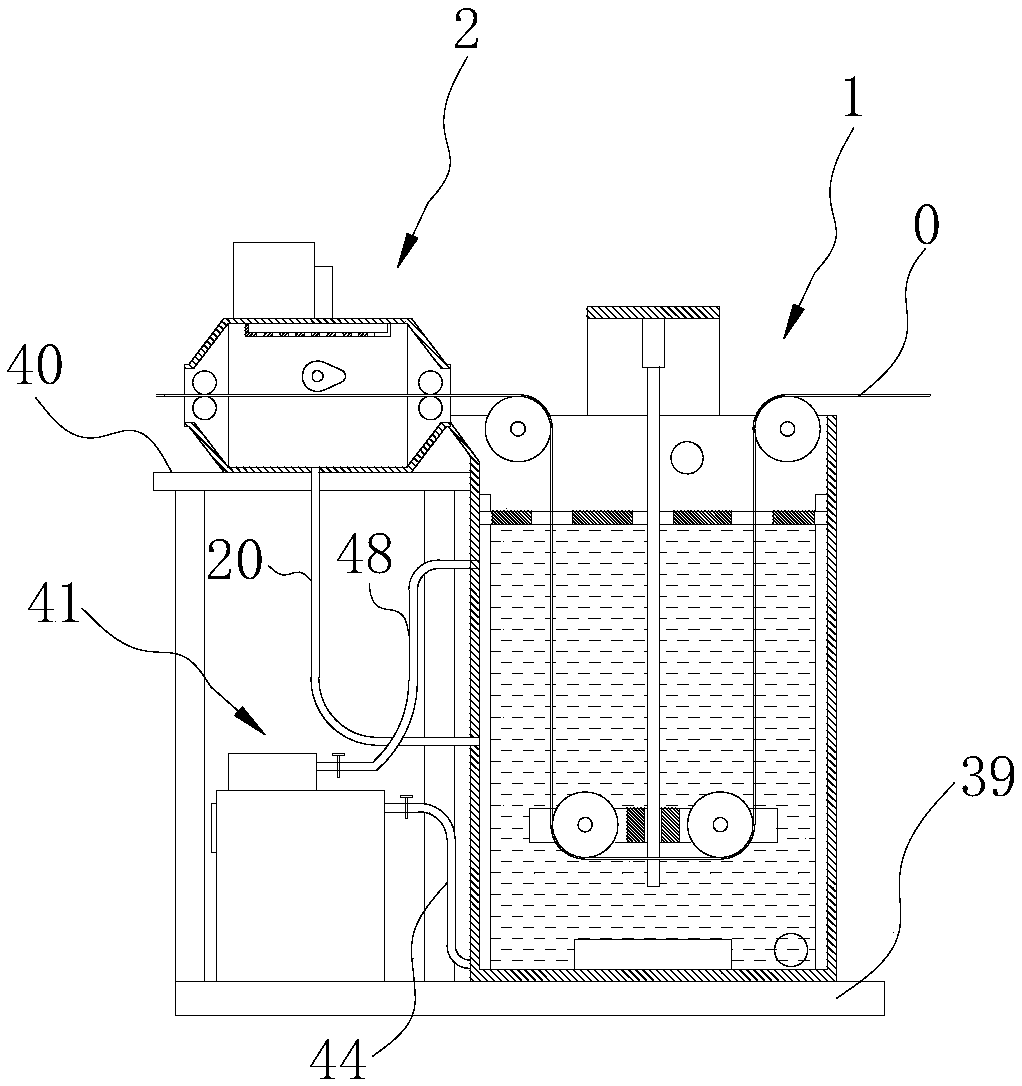

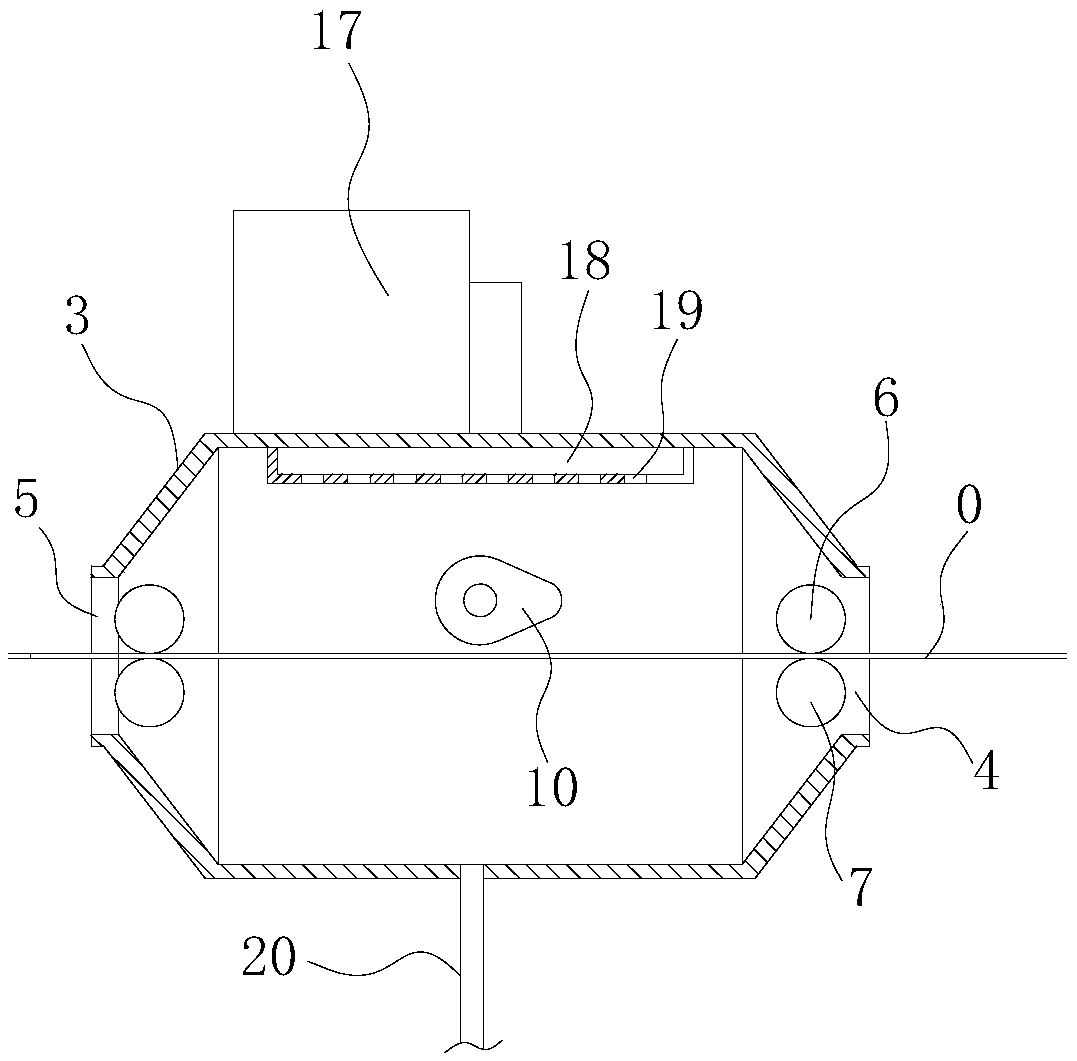

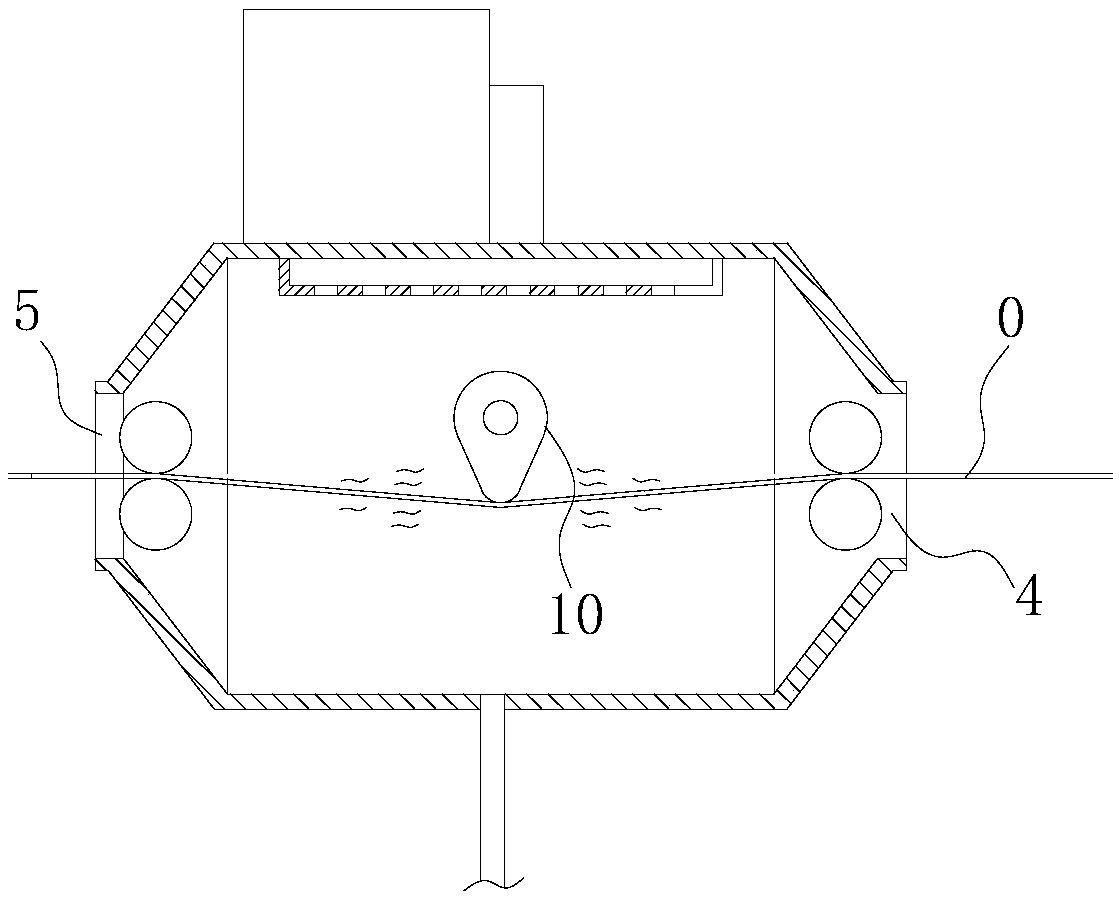

[0030] Such as Figure 1-9 A new type of yarn dipping oiling machine shown includes a dipping type oiling device 1 and an elastic degreasing device 2 located on one side of the dipping type oiling device 1, and the dipping type oiling device 1 is passed through The oiling device for oiling the yarn O by means of dip dyeing has an oil container containing oil 24 . The spring-type degreasing device 2 is used to remove the excess oil 24 entrained on the yarn 0 after dipping. 2. Remove excess oil 24 by vibrating the yarn 0. Yarn 0 passes through the dip-dyeing oiling device 1 and the spring-type oiling device 2 sequentially along the conveying direction, that is to say, the yarn 0 passes through the dip-d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com