Textile line dyeing device for textile industry

A dyeing device and textile thread technology, applied in the field of textile thread dyeing, can solve the problems of uneven dyeing, low work efficiency, high cost, etc., and achieve the effect of ensuring uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

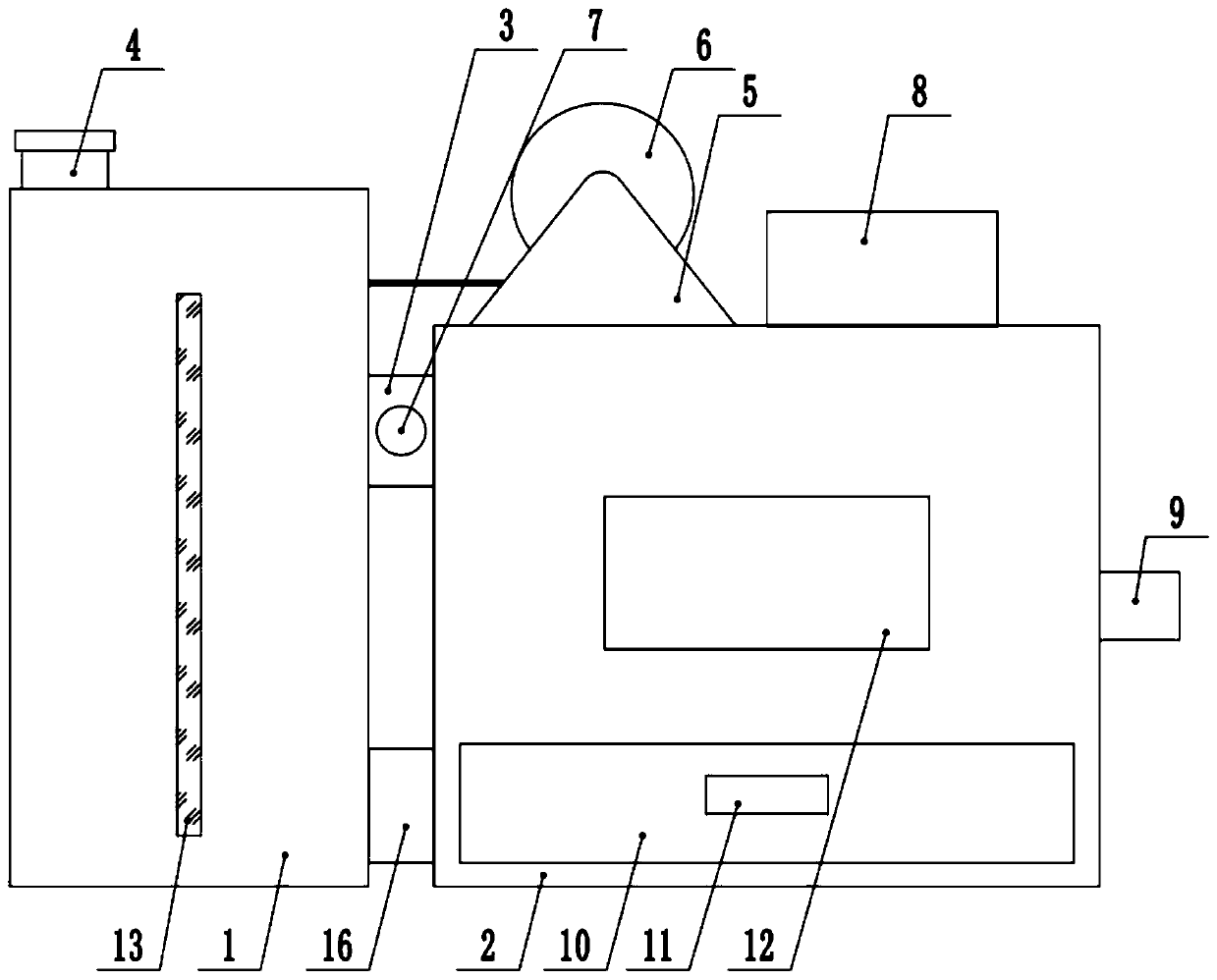

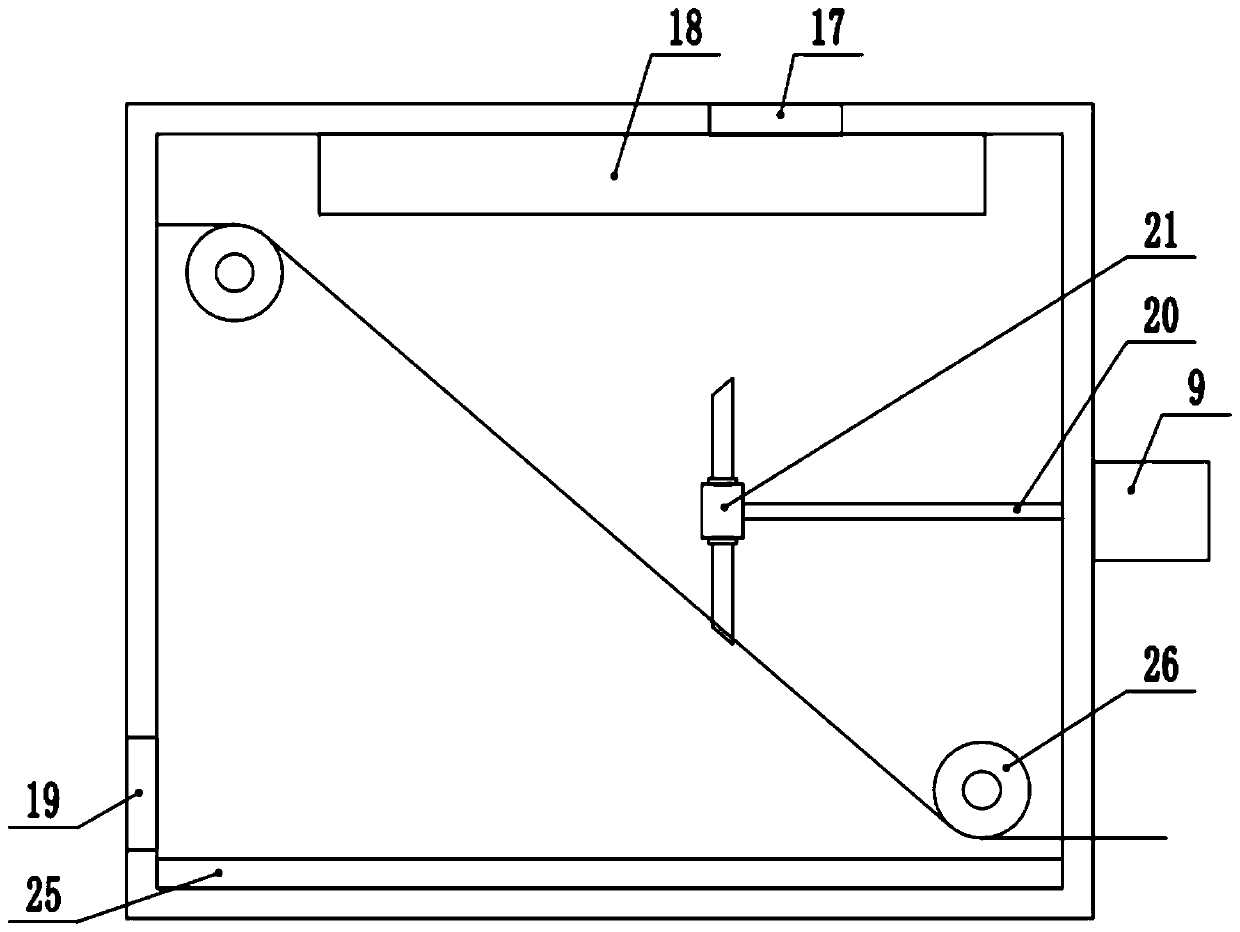

[0027] see Figure 1-4 , a textile thread dyeing device for the textile industry, comprising a dye box 1 and a drying box 2, a connection cover 3 is fixedly connected between the dye box 1 and the drying box 2, the inside of the dye box 1 is provided with a thread dyeing mechanism, and the drying box 2 is equipped with a springing device and a drying mechanism. The top of the drying box 2 is fixedly connected to the top seat 5, and the top seat 5 is connected to the pay-off wheel 6. The pay-off wheel 6 is wound with a textile thread, and the textile thread passes through the dye. After the box 1 enters the connection cover 3 and then enters the drying box 2 for final output, the top end of the dye box 1 is fixedly connected to the feed port 4 .

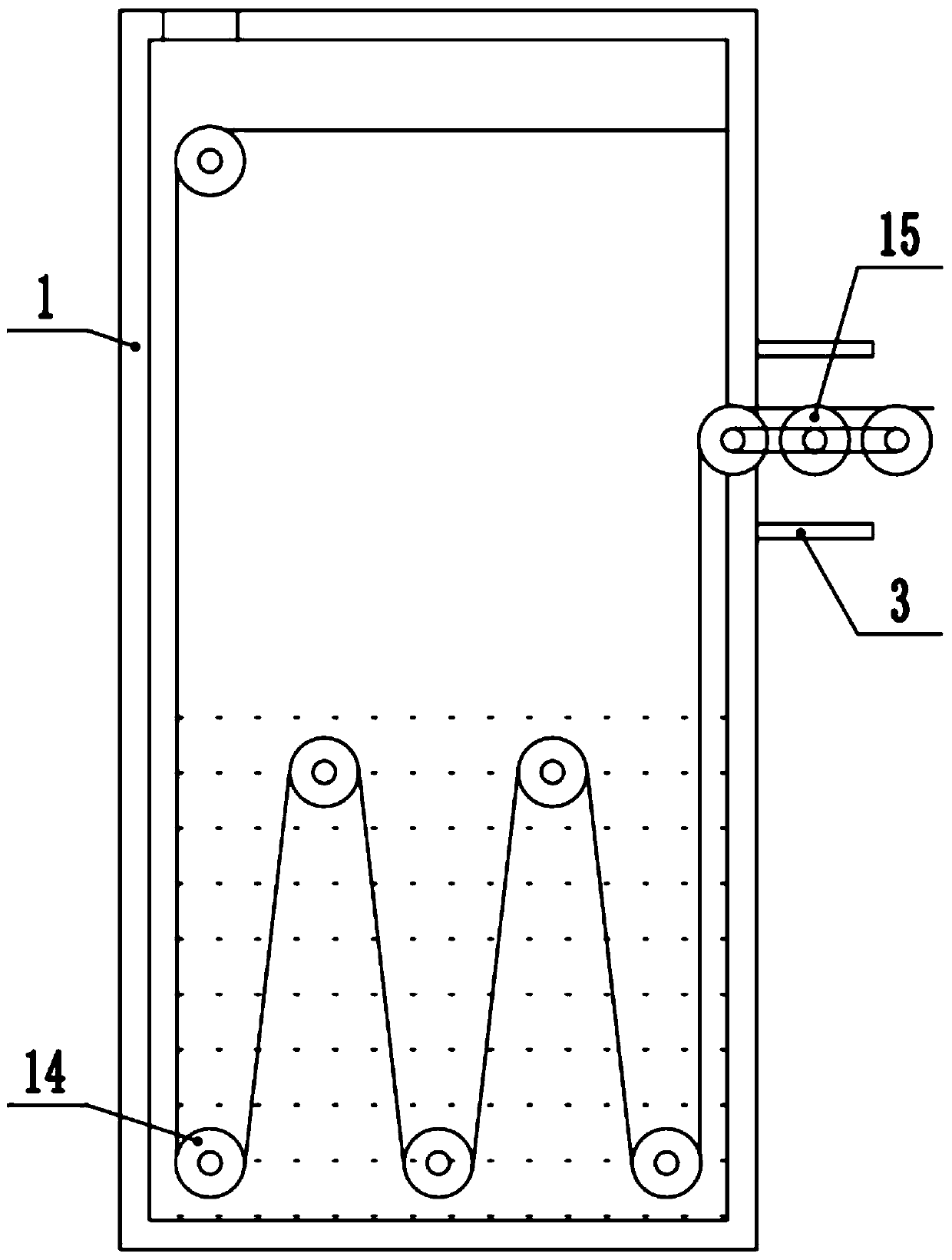

[0028] The thread dyeing mechanism includes a plurality of first inner drive rollers 14 arranged in the dye box 1, the first inner drive rollers 14 are rotatably connected to the inner wall of the dye box 1, and the connecting cover 3...

Embodiment 2

[0036] see Figure 1-4, the other content of this embodiment is the same as that of Embodiment 1, the difference is that: the bottom end in the drying box 2 is placed with a collection tray 25, and the drying box 2 on one side of the collection tray 25 is rotatably connected with a revolving door 10, The revolving door 10 is fixedly provided with a handle 11 . The outside of the dye tank 1 is fixedly connected with a liquid level gauge 13, and the outside of the drying box 2 is fixedly connected with a touch screen 12, and a controller is integrated in the touch screen 12.

[0037] The present invention can dye the textile thread released from the pay-off wheel by arranging a thread dyeing mechanism in the dye box 1, and can continuously stir the dyed textile thread by arranging an elastic thread device, so that the redundant dye on the textile thread can be dyed. It is bounced off to ensure the uniformity of dyeing. By setting a drying mechanism in the drying box 2, the dyed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com