Dyeing device for jeans production

A technology for dyeing devices and jeans, applied in the field of dyeing devices, can solve the problems of shaking separation, reducing the efficiency of jeans dyeing, consuming workers' time and labor, and achieving the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

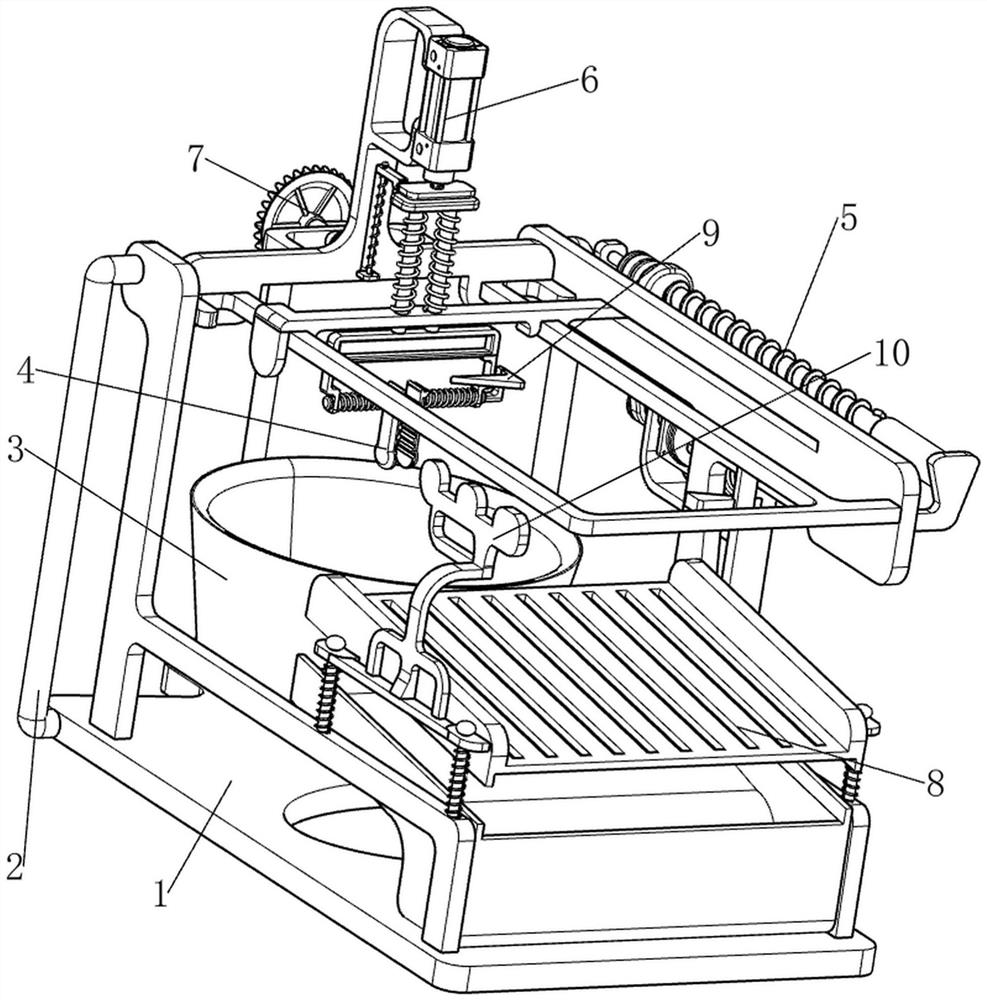

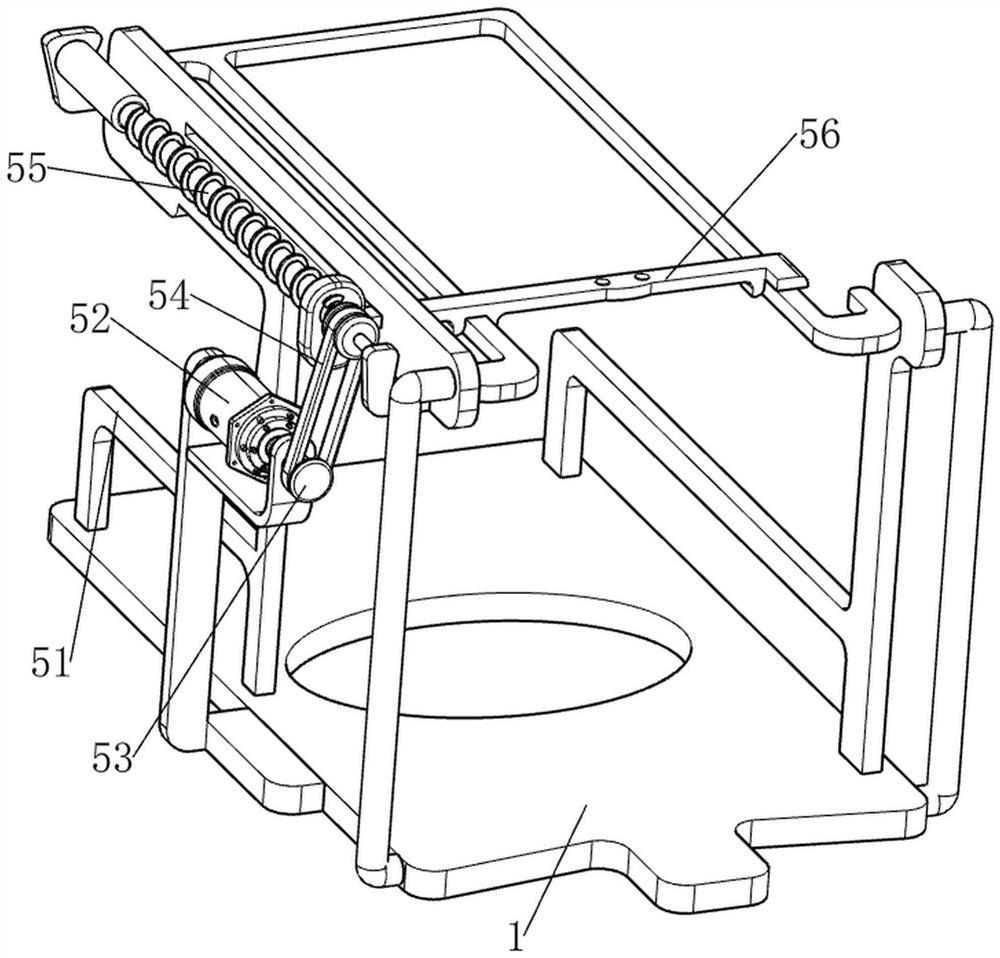

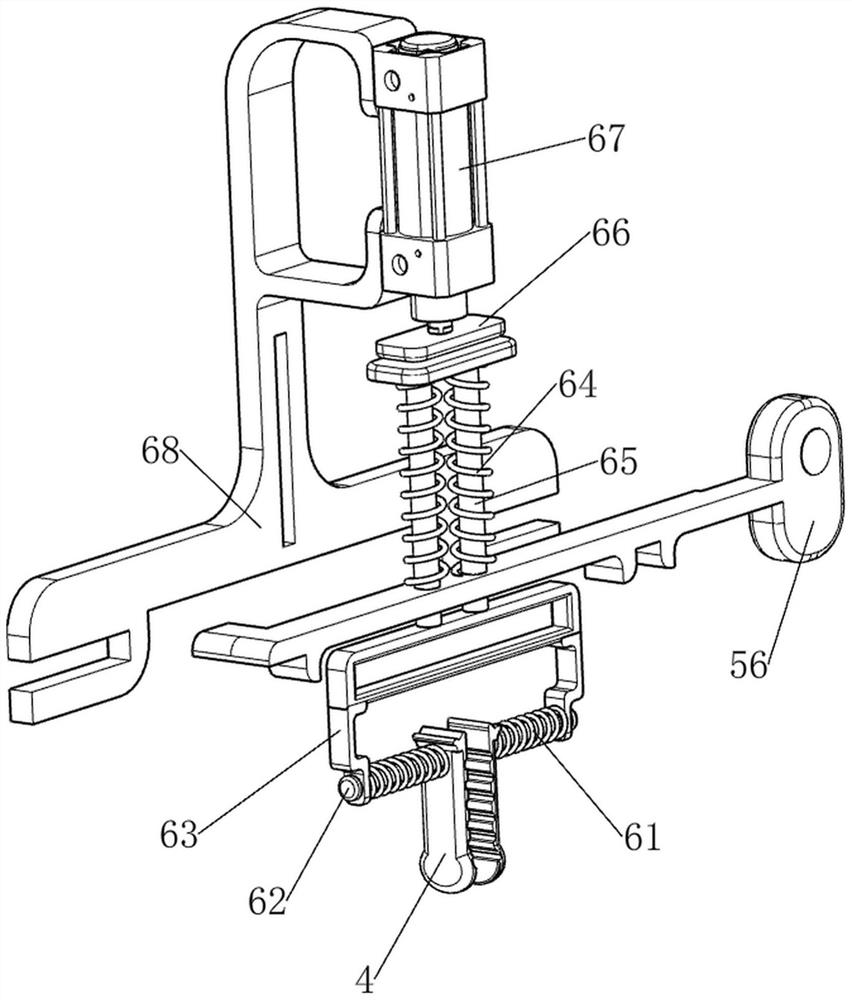

[0068] A dyeing device for jeans production, such as Figure 1-3As shown, it includes an underframe 1, a first support rod 2, a rotating frame 3, a clamp block 4, a feeding mechanism 5 and a pressing mechanism 6, and the left and right sides of the rear part of the underframe 1 are provided with first support rods 2. The rear part of the frame 1 is rotatably provided with a rotating frame 3, and a feeding mechanism 5 is connected between the two first support rods 2 and the bottom frame 1. The upper sliding type of the feeding mechanism 5 is provided with a down-pressing mechanism 6, and the lower part of the down-pressing mechanism 6 Both left and right sides are provided with clamping blocks 4 .

[0069] The worker first clamps the jeans through the clamping block 4, the worker pours the dye into the rotating frame 3, and then starts the feeding mechanism 5, the operation of the feeding mechanism 5 drives the operation of the pressing mechanism 6, and the operation of the pr...

Embodiment 2

[0075] In a preferred embodiment of the present invention, as figure 1 with Figure 4-7 As shown, a reciprocating mechanism 7 is also included, and the reciprocating mechanism 7 includes a second transmission assembly 71, a second rotating shaft 72, a bevel gear set 73, a third rotating shaft 74, a shaft sleeve 75, an orientation gear 76, a rack 77, a third Spring 78, second sliding rod 79 and lower pressing block 710, the bottom frame 1 is equipped with a second rotating shaft 72 in a rotating manner at the rear, and a second transmission assembly 71 is connected between the lower side of the second rotating shaft 72 and the lower side of the rotating frame 3 , the second transmission assembly 71 is made up of two second pulleys and a second belt, one second pulley is connected to the lower side of the second rotating shaft 72, the other second pulley is connected to the lower side of the rotating frame 3, and the second belt is wound around the two sides. Between the two se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com