Novel gas-fog dyeing machine

A dyeing machine and aerosol technology, which is applied in the field of dyeing machines, can solve problems such as high liquor ratio, high liquid flow density, and damage to fabric structure, and achieve the effects of reducing liquor ratio, promoting environmental protection, and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

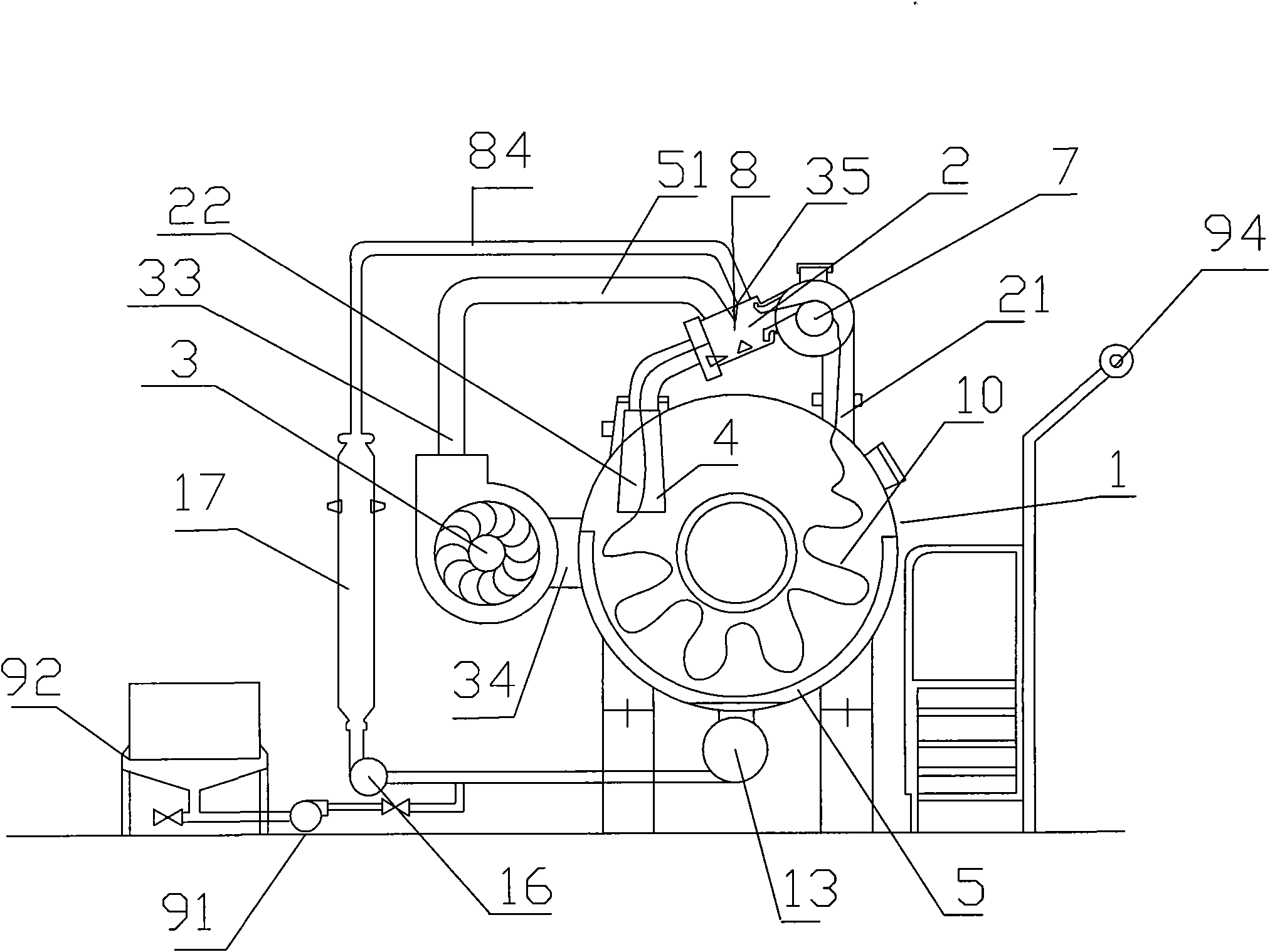

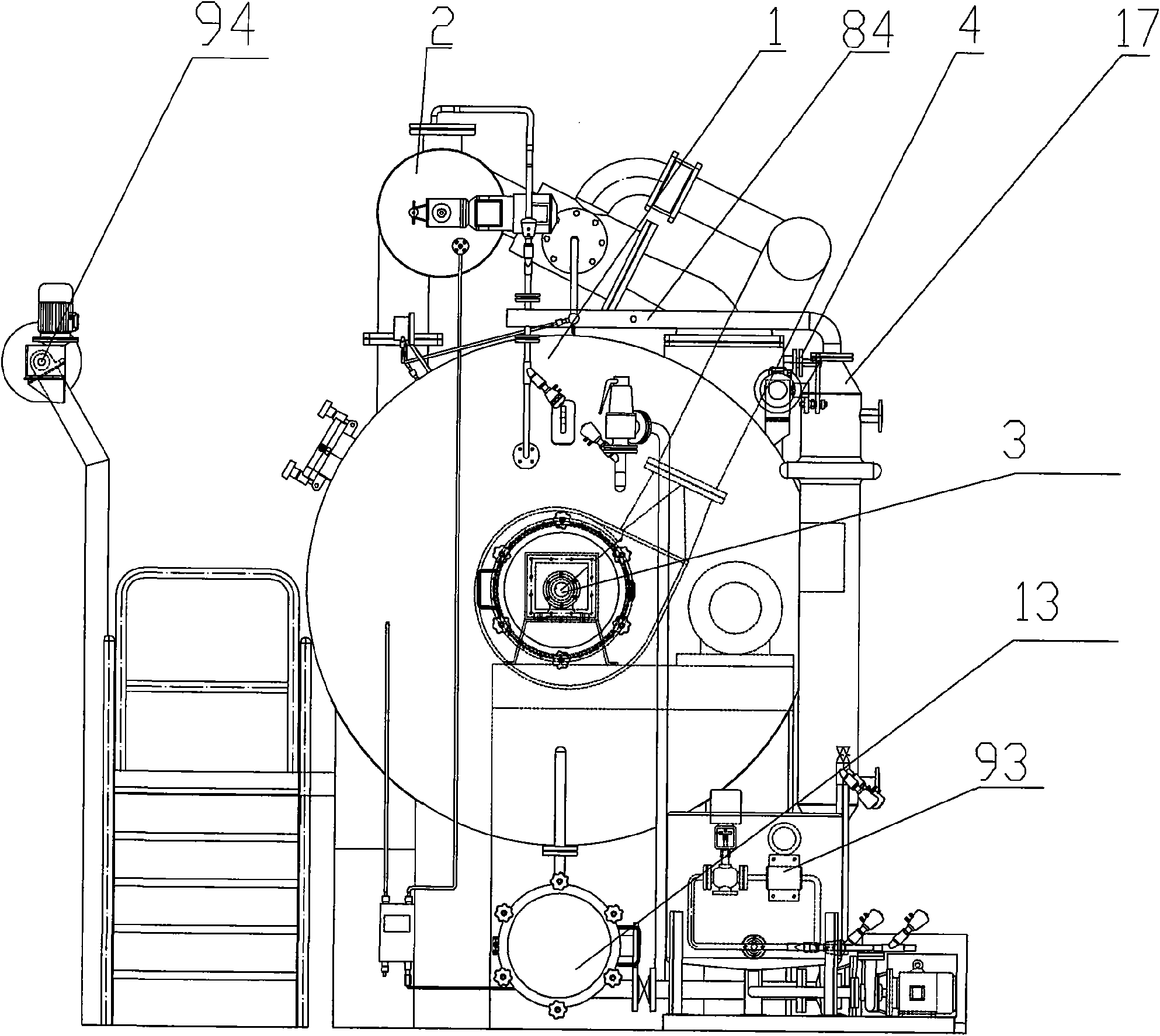

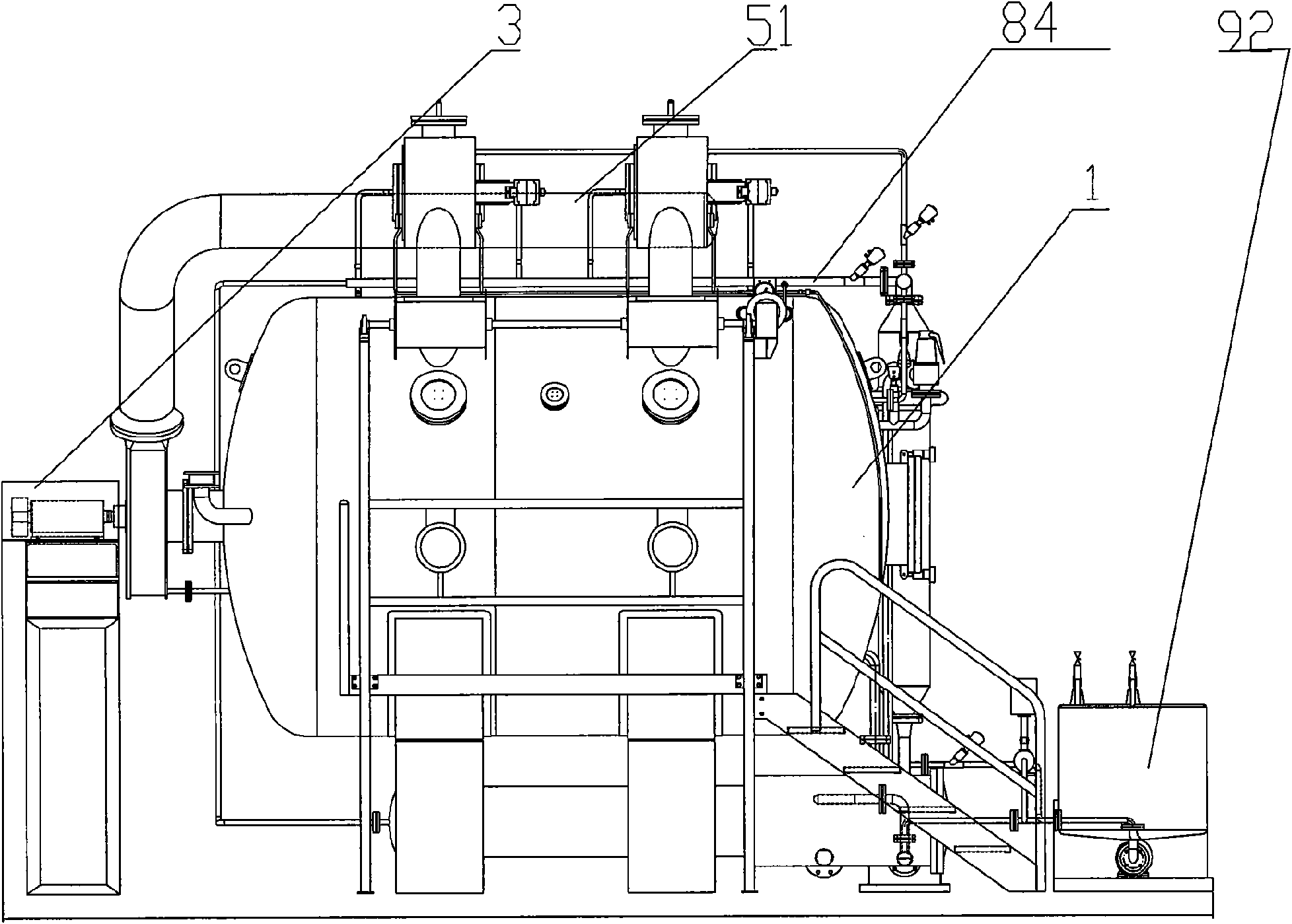

[0019] Refer to attached figure 1 , 2 , 3, 4, 5, 6, 7, 8. The present invention includes a main cylinder body 1, a high-pressure blower 3 and a nozzle atomization system 2, an outlet 33 of one end of the high-pressure blower 3 communicates with a high-pressure air inlet 35 in the nozzle atomization system; the two ends of the nozzle atomization system 2 are The fabric inlet 21 and the fabric outlet 22 communicate with the main cylinder 1 respectively; the nozzle atomization system 2 is provided with a dye solution cutting nozzle 96, an energy conversion nozzle 8 and a cloth lifting roller 7. The nozzle atomization system is also provided with a dye solution inlet 23 .

[0020] Refer to attached Figure 10 Described dye liquor cutting nozzle 96 is annular slit shape, with reference to attached Figure 7 The axial section of the energy conversion nozzle 8 is composed of three sections: a straight pipe section 81, a tapered section 82 and a gradually expanding section 83. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com