Ultra-low bath ratio yarn dyeing machine water-squeezing device and squeezing method thereof

A yarn dyeing machine, ultra-low bath technology, used in textiles and papermaking, liquid/gas/vapor removal, textile material processing, etc., can solve the problems of inability to meet dyeing requirements, waste, and increased drainage time for dyed yarns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] The specific implementation of the present invention will be further described below in conjunction with the accompanying drawings, but the implementation and protection scope of the present invention are not limited thereto.

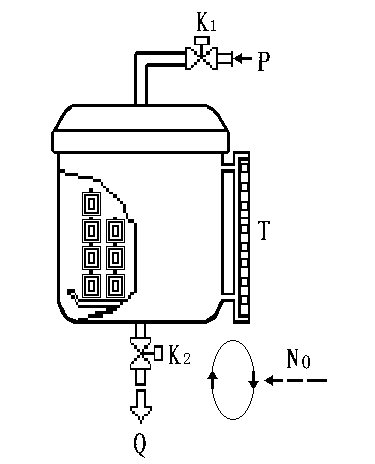

[0069] The principle of squeezing water is as figure 1 as shown, figure 1 Air pressure input pipe P; squeeze water outlet Q for draining residual water; water level display scale T; cycle number NO; compressed air squeeze water valve K 1 ;Stamped water discharge valve K 2 . Among them, the process of squeezing water and dyeing process is as follows: Dyeing process starts→water intake→add dyestuff→add sodium starch→add soda ash→circulate for 30min→pulse washing water→water level drainage→water intake→soaping→water level drainage→ Squeeze water (pressure dehydration) → complete. The invention adopts pressure dehydration to realize the dehydration of the spindle, and at the same time reduces the residual water of the spindle, which is beneficial...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com