Novel drum type scouting machine

A drum-type, new technology, applied in the field of scouring machines, can solve the problems of poor scouring agent concentration and temperature uniformity, small drum space for cloth, inaccurate temperature control, etc., and achieves low labor intensity for workers and less human intervention factors. , good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

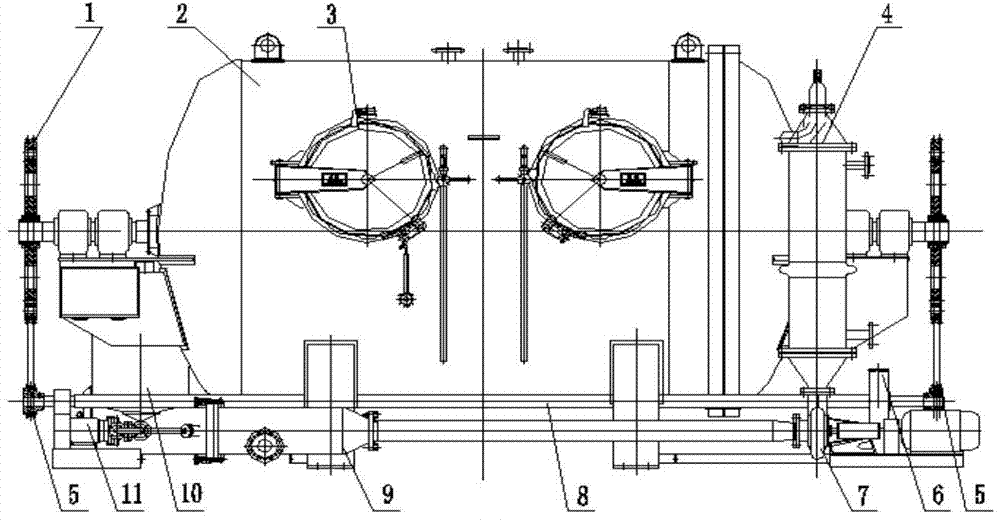

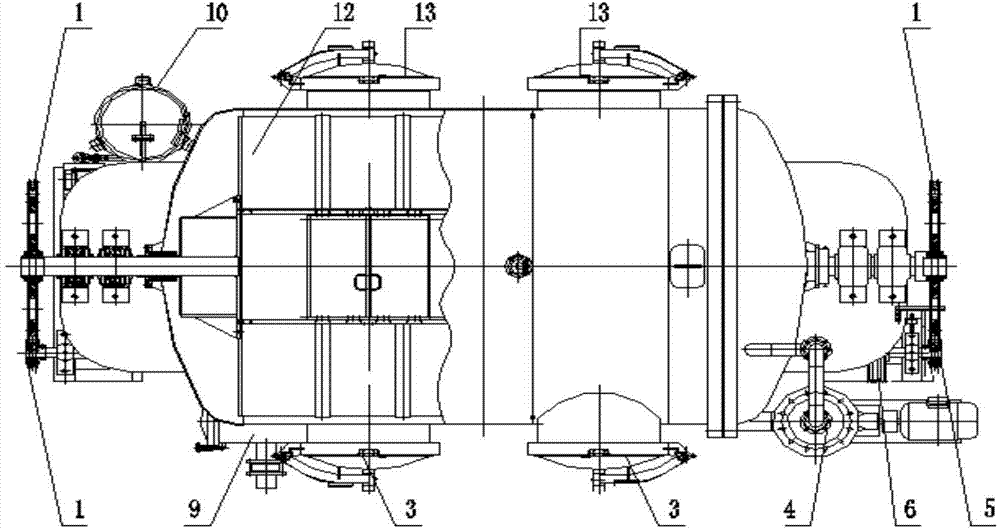

[0020] Such as Figure 1 to Figure 5 , the main cylinder body (2) is provided with two quick-opening doors (3) for the cloth inlet operation port, from which the scoured fabric enters the drum (12) in the cylinder for processing, after processing, it is quickly opened from the corresponding cloth outlet operation port Open the door (13) and take it out.

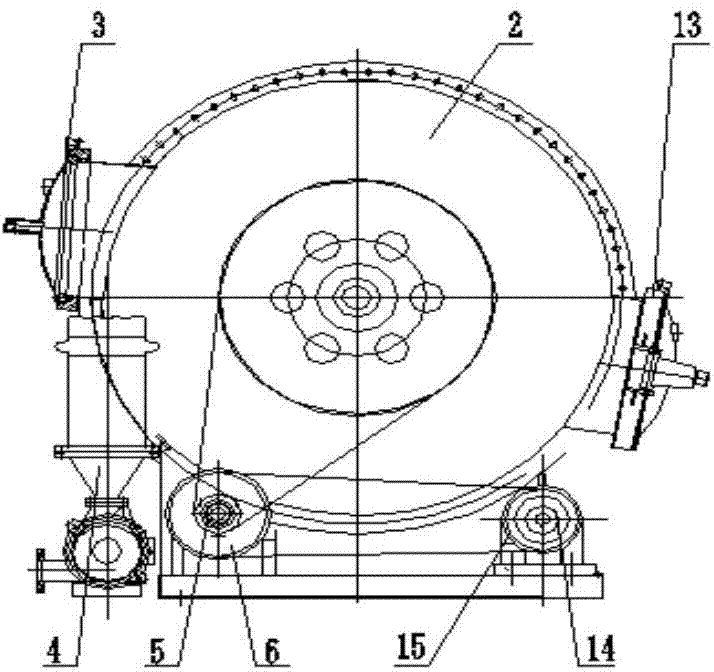

[0021] Such as Figure 4 , the drum (12) is provided with a drum operation movable door (19), and the fabric to be processed enters the cylinder (2) from the operating port and then enters the inside of the drum through the movable door. A reinforcement ring (20) is provided on the outer ring of the drum (12) for reinforcement, and a rectangular square tube (21) is provided inside, so that the drum can effectively drive and knead the fabric when it rotates. Both ends of the drum (12) are connected to the shaft head (18), and the shaft head (18) is connected to the main cylinder body (2) through the bearings (16) at both ends...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com