Sizing machine

A pulp machine and pulp tank technology, which is applied in textile processing machine accessories, textiles and papermaking, and textile material processing, can solve the problems of easy dripping, falling off, and waste of slurry, so as to improve the efficiency of sizing, avoid waste, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The preferred embodiments of the present invention will be described in further detail in conjunction with the accompanying drawings.

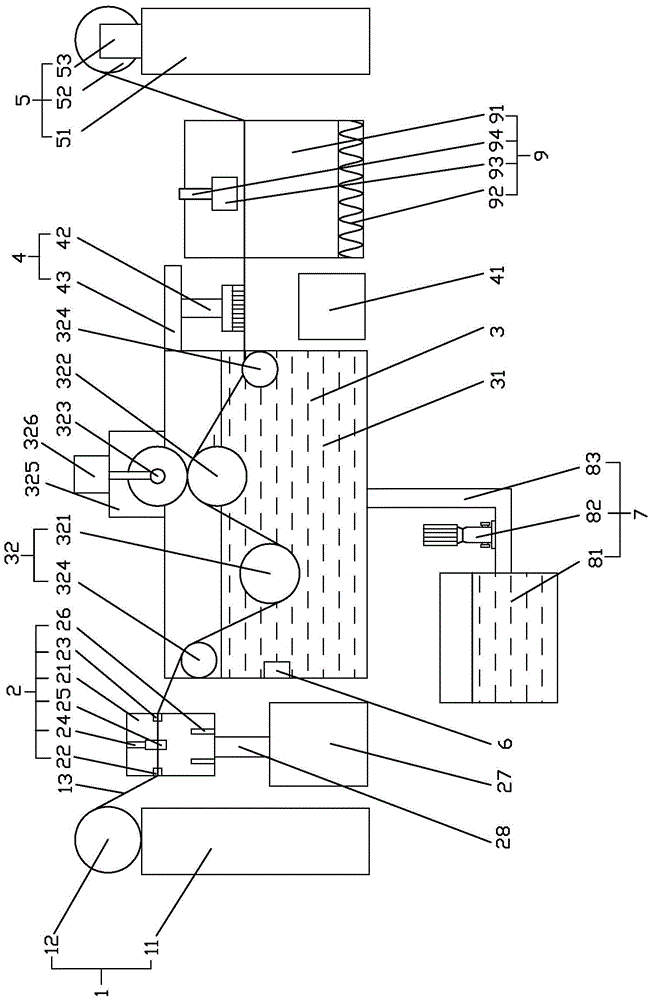

[0015] like figure 1 A sizing machine shown includes a yarn releasing device 1 , a pre-cleaning device 2 , a sizing mechanism 3 , a size recovery device 4 and a yarn receiving device 5 . The yarn releasing device 1 comprises a yarn releasing frame 11 and a yarn releasing roller 12 positioned on the yarn releasing frame 11, and the yarn receiving device 5 comprises a yarn receiving frame 51, a yarn receiving roller 52 positioned on the yarn receiving frame 51 and a motor 53 , the rotating shaft of the motor 53 is connected with the rotating shaft of the take-up roller 52, and the motor 53 drives the take-up roller 52 to rotate. The pre-cleaning device 2 is located on the yarn feeding side of the sizing mechanism 3, and the pre-cleaning device 2 includes a vacuum cleaner 21 in a hollow structure. The vacuum cleaner 21 includes a yarn in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com