EPS rack clearance buffering stop block assembly

A buffer block and rack technology, which is applied to vehicle components, mechanical steering gears, steering mechanisms, etc., can solve the problems of poor manufacturing process, prominent abnormal noise, easy wear, etc., and achieve low friction coefficient, good impact resistance, Good crafting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

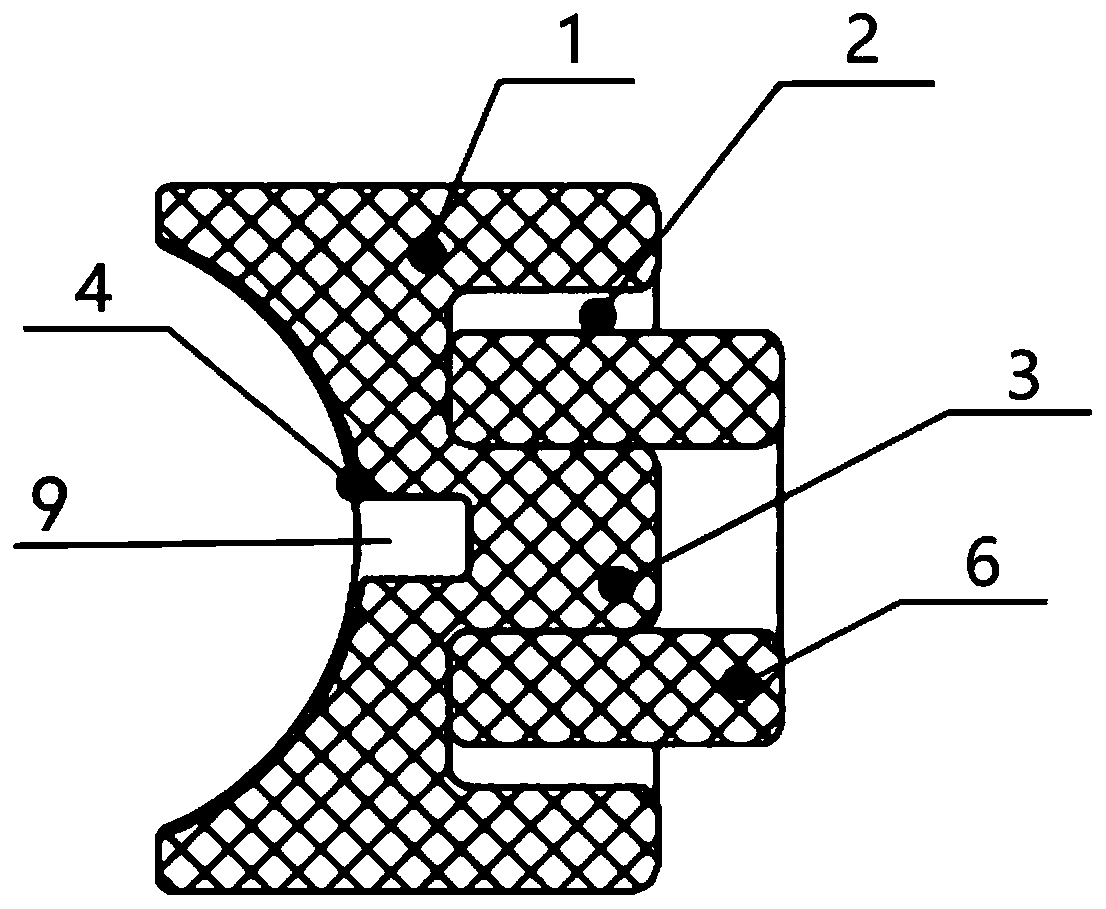

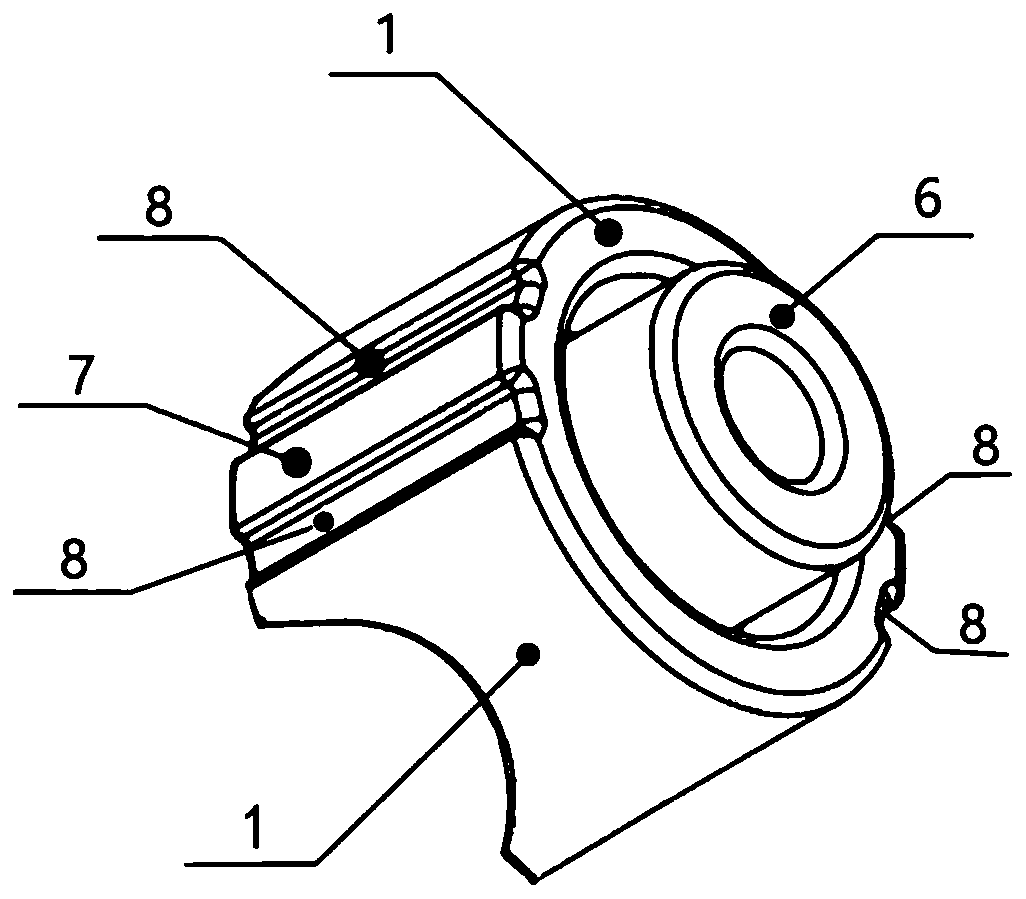

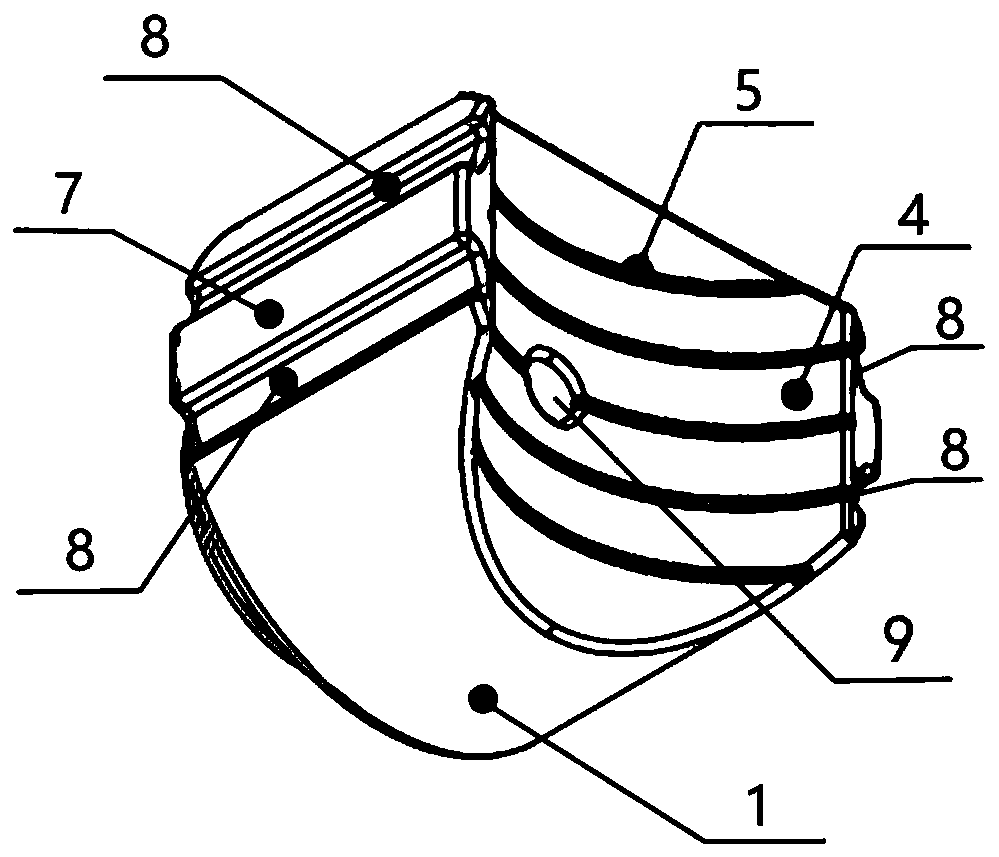

[0019] Examples such as figure 1 The shown EPS rack gap buffer stopper assembly includes two components of a press block cylinder 1 and a rubber ring 6, and the bottom of the press block cylinder 1 is provided with a concave arc-shaped rack contact surface 4, A recessed annular groove 2 is provided on the top of the briquetting cylinder 1, and a protruding rubber ring positioning platform 3 is arranged in the middle of the annular groove 2; the rubber ring 6 is arranged in the annular groove 2, as figure 2 with Figure 4 As shown, the rubber ring 6 is inserted into the rubber ring positioning platform 3 in the annular groove 2 of the briquetting cylinder 1 , and is limited in the briquetting cylinder 1 by the rubber ring positioning platform 3 .

[0020] The rubber ring 6 in the present invention is used to replace the traditional spring, has a certain compression deformation capacity, is made of injection-molded rubber material, and has the functions of anti-collision, shoc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com