Feeding throat pipe

A throat and material feeding technology, which is applied in the field of office supplies, can solve problems such as wire blocking, and achieve the effect of smooth wire output, simple structure, and excellent use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

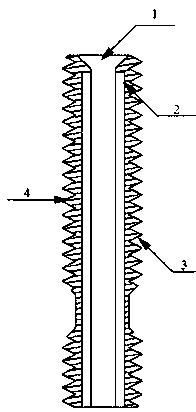

[0013] like figure 1 As shown, a feed throat, the feed throat is a hollow structure, the feed throat includes a feed throat mouth 1, the feed throat inner wall 2 and is arranged on the feed throat outer wall and is used for The feeding thread 3 fixed with the heating aluminum block, the inner wall 2 of the feeding throat is provided with a Teflon tube 4 or the inner wall 2 of the feeding throat is coated with a Teflon coating. The feed throat opening 1 includes an outer opening and an inner opening, the diameter of the outer opening is greater than that of the inner opening, and the inner opening coincides with the opening of the Teflon tube 4 .

[0014] Specific work engineering:

[0015] like figure 1 As shown, after the printing filament enters from the feed throat, it continues to be transported along the Teflon tube. The non-stick and sliding properties of the Teflon tube can greatly reduce the friction between the printing filament and the inner wall of the feed throat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com