Separating mechanism for flexible teflon cloth

A technology of separation mechanism and Teflon cloth, which is applied in the direction of pile separation, object separation, thin material processing, etc., can solve the problem that materials cannot be separated, and achieve the effect of improving efficiency and convenient and fast separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the object, technical scheme and advantages of the present invention clearer, the following combination Attached picture The present invention is described in further detail.

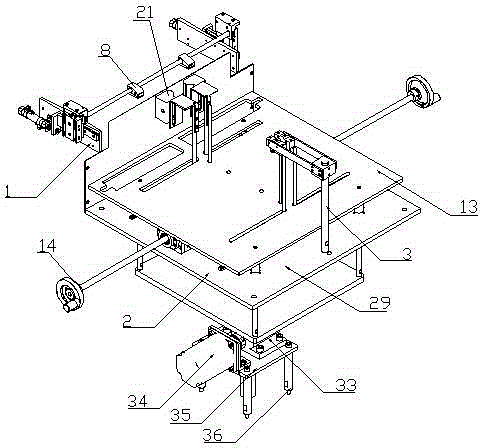

[0018] figure 1 Shows the flexible Teflon cloth separation mechanism of this embodiment, which is composed of three mechanisms: the separation mechanism 1, the upper material bin body mechanism 2 and the height detection mechanism 3. The positional relationship is: the upper material bin body mechanism 2 is the center, the height The detection mechanism 3 is located at the head end of the loading bin body mechanism 2, and the separation mechanism 1 is arranged at the tail end of the loading bin body mechanism 2.

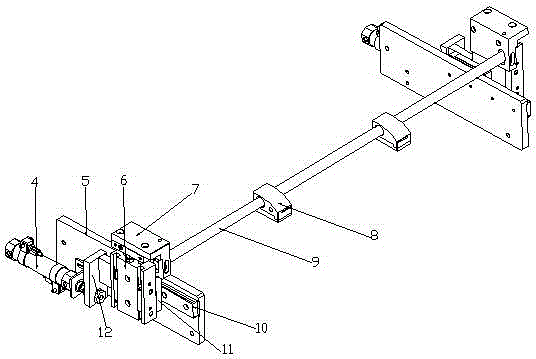

[0019] figure 2 It is a separation mechanism structure containing mini air knife 8 picture , this mechanism takes the center of the cross brace 9 as the symmetry point, and the structures at the left and right ends are symmetrical, wherein the left end has a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com