LED (light-emitting diode) series SMT (surface-mount technology) suction nozzle and manufacturing process thereof

A series and nozzle technology, applied in the field of LED series SMT nozzles, can solve the problems of LED sticking to the nozzles, anti-adhesion, low throwing rate, etc., to avoid scratches, reduce defective rates, and save costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

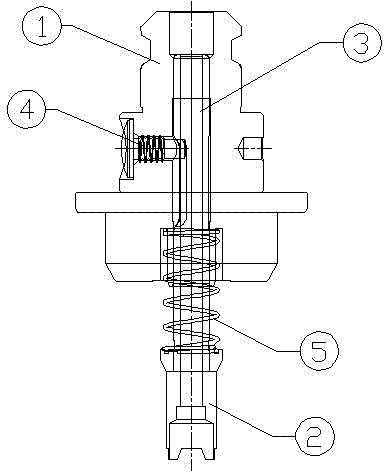

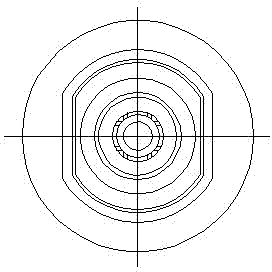

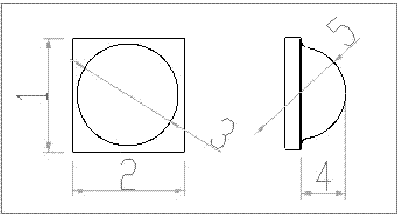

[0025] Including mouthpiece 2, mouthpiece 1, core 3, screw 4, spring 5, such as figure 1 , 2 As shown, the nozzle head 1 is a semi-rigid composite material of anti-adhesive material, and the semi-rigid composite material includes Teflon Teflon, polyethylene, and polypropylene are configured in a ratio of 65:25:10 by weight; the core 3 is connected to the nozzle head 1, the spring 5 is covered with the core 3, and the nozzle seat 1 is screwed 4 fixed core 3.

[0026] The mouthpiece 1 is stainless steel 303CU.

[0027] Suction nozzle manufacturing process, including steps,

[0028] 1) mouth making

[0029] a) The ingredients of the semi-rigid composite material are configured according to the ratio of 65:25:10 by weight, and the Teflon Teflon is added to the mixer for baking and melting; then polyethylene and polypropylene are added to the mixer for uniform mixing to form a semi-rigid composite material;

[0030] b) Injection molding, design the injection mold...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com