Intelligent super-long paste extruder for production of Teflon insulating tube

An insulating tube and Teflon technology, applied in the field of intelligent ultra-long paste extruder, can solve the problems of easy deviation of finished tube size and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

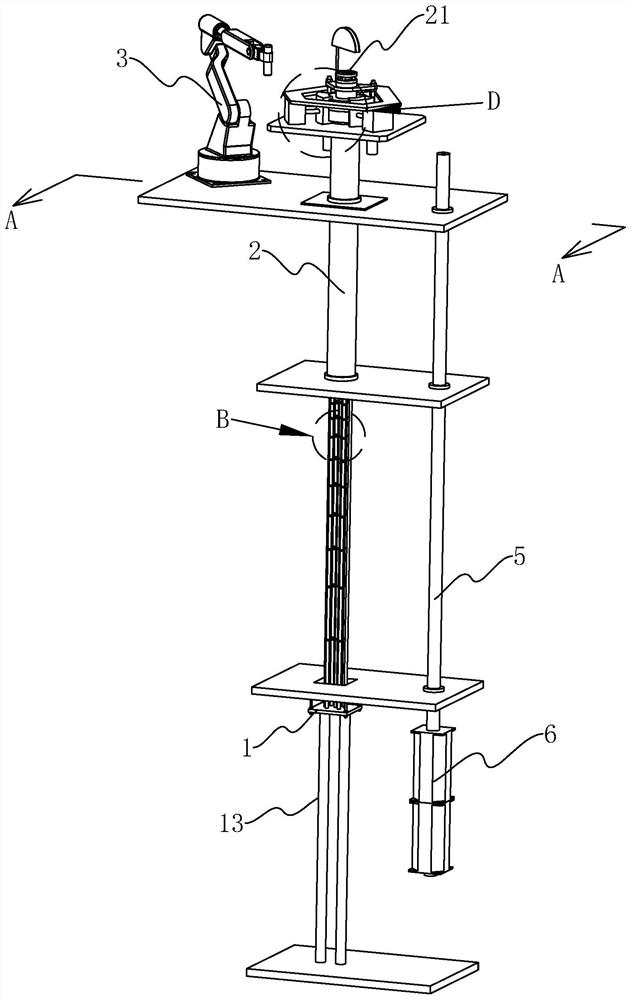

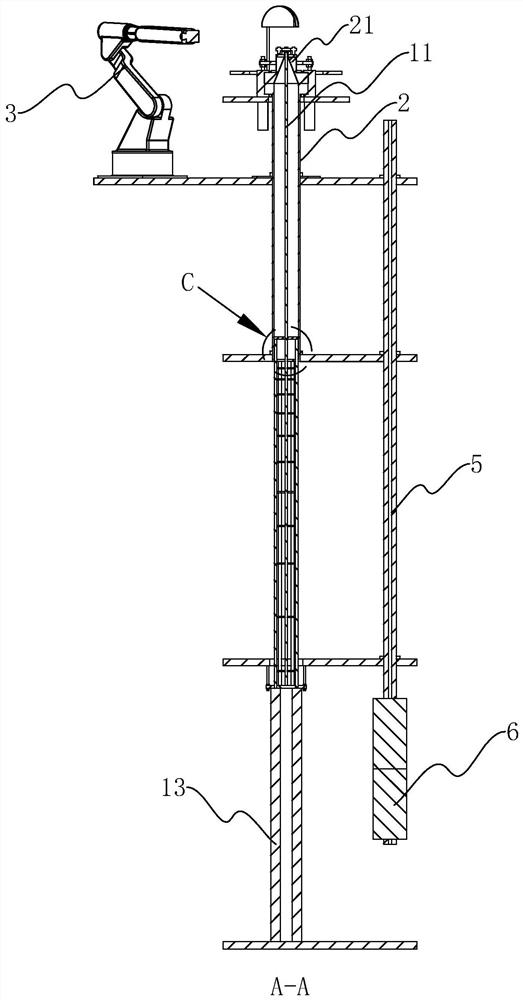

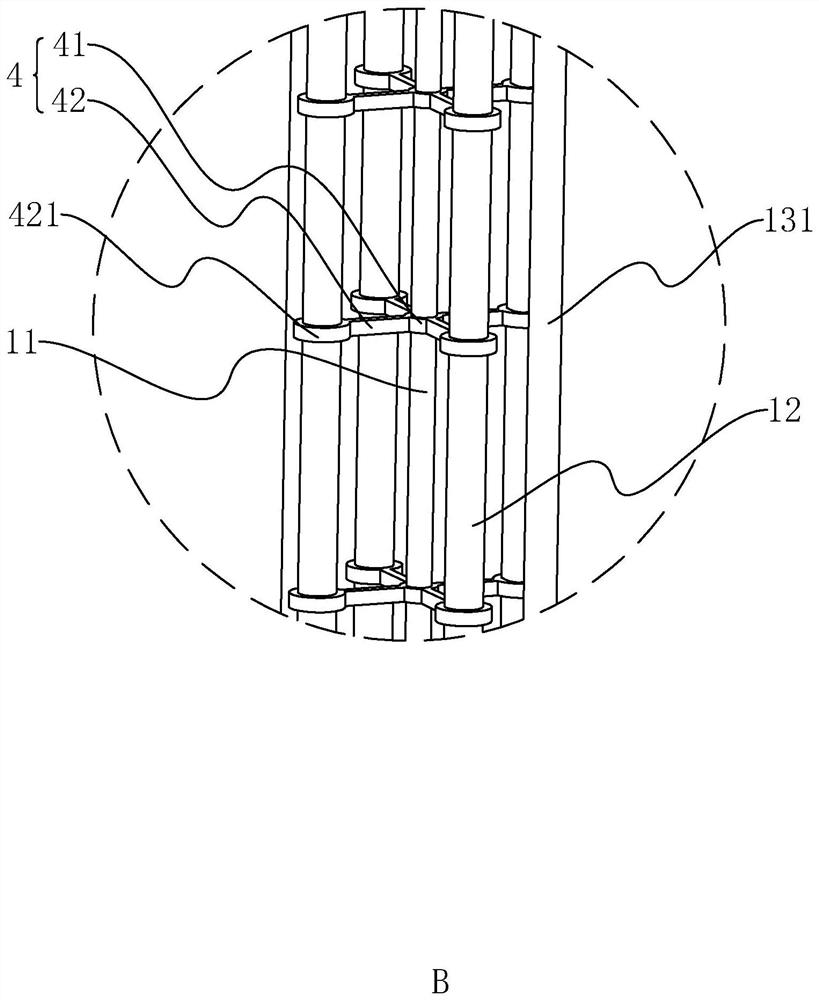

[0042] The embodiment of the present application discloses an intelligent ultra-long paste extruder for the production of Teflon insulating pipes. refer to figure 1 and figure 2 , the intelligent ultra-long paste extruder for the production of Teflon insulating pipes includes a reference plate 1 and a barrel 2 erected above the reference plate 1. The reference plate 1 can be in the shape of a cuboid, a disc or a triangle. In the embodiment of the present application, the reference plate 1 is in the shape of a cuboid. The length direction of the barrel 2 is arranged in the vertical direction and the peripheral wall can be fixed on the floor of the workshop. The length of the barrel 2 is between 0mm and 10000mm. In the embodiment of the present application, the length of the barrel 2 is 7000mm. A detachable die head 21 is provided at the end of the barrel 2 away from the reference plate 1 . A manipulator 3 for loading is provided on the top periphery of the barrel 2, and the...

Embodiment 2

[0053] refer to Image 6 and Figure 7 , the difference between Embodiment 2 of the present application and Embodiment 1 lies in the sheath assembly 4: the sheath assembly 4 includes a plurality of correction rings 43, adjustment telescopic rods 44, and support rods 45 (refer to Figure 8 ) and the first curved plate 46 (refer to Figure 8 ), the plurality of correction rings 43 correspond to the plurality of guide rods 12 one by one, and the correction rings 43 are sheathed on the outer peripheral wall of the guide rod 12 , and the correction rings 43 can move along the axial direction of the guide rod 12 . Between the correction ring 43 and the guide rod 12, there is a limiter for restricting the movement of the correction ring 43. The limiter includes a limit screw 431, and one or more limit screw 431 can be provided. In the embodiment of the present application In the first option, the correction ring 43 is provided with a threaded hole (not shown in the figure) that is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com