Milling cutter for processing flexible board

A flexible board and milling cutter technology, applied in milling cutters, metal processing equipment, manufacturing tools, etc., can solve the problems of poor rigidity of milling cutters, poor cutting performance, and inability to meet the milling accuracy of groove bottom and chamfering surface at the same time, and achieve Increased service life, high processing efficiency, and improved milling quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

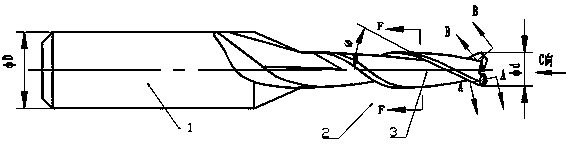

[0032] figure 1 Shown is a milling cutter for processing flexible boards according to the present invention, which includes a tool holder 1, one end of which is extended into a milling cutter head 2, and the surface of the milling cutter head 2 is formed with two circles in the same direction. The spiral groove 3 forms a milling edge, and the end of the milling bit 2 is provided with a cutting surface of a V mouth; the end of the cutting surface is provided with a chamfer to form a chamfer edge; the angle of the chamfer is 45 °, The angle ω of the helix angle of the helical groove 3 is 30°.

[0033] The outer diameter φD of the shank 1 is 3.175 mm, the outer diameter φd of the milling head 2 is 1.8 mm, and the core circle diameter φK of the milling head 2 is 50% of the outer diameter φd of the milling head 2, That is 0.9mm.

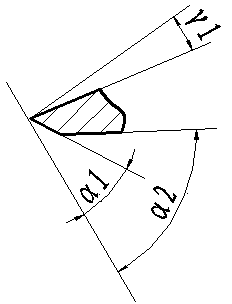

[0034] The milling cutter is formed with double-ended teeth, such as figure 2 Shown is the A-A view obtained by cutting along the direction perpendic...

Embodiment 2

[0049] Embodiment 1 of the milling cutter for processing flexible boards in this embodiment is basically the same, and the difference lies in:

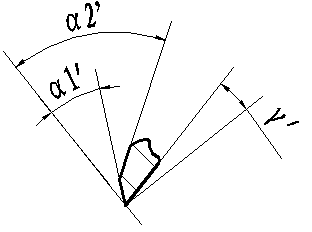

[0050] The angle ω of the helix angle of the helical groove 3 is 32°. The milling cutter is formed with double-end teeth, one end tooth relief angle α1 is 13°, the other end tooth relief angle α2 is 29°, and the end tooth rake angle γ1 is 4°. The side of the chamfering edge is formed with double-end teeth, wherein the chamfering relief angle α1' of one end tooth is 10°, and the chamfering relief angle α2' of the other end tooth is 27°. The rake angle γ1' is 4°. The rake angle γ of the milling cutter is 4°. , the outer diameter φD of the tool holder 1 is 3.175mm, and the outer diameter φd of the milling head 2 is 0.4mm. The core diameter φK of the milling head 2 is 0.20 mm. The distance e between one edge of the end teeth of the milling cutter and the center is 0.02 mm. The end tooth of the milling cutter is a Closed groove type, ...

Embodiment 3

[0052] Embodiment 1 of the milling cutter for processing flexible boards in this embodiment is basically the same, and the difference lies in:

[0053] The angle ω of the helix angle of the helical groove 3 is 28°. The milling cutter is formed with double-end teeth, wherein one end tooth relief angle α1 is 17°, the other end tooth relief angle α2 is 31°, and the end tooth relief angle γ1 is 8°. The chamfering edge is formed with double-ended teeth, wherein the chamfering relief angle α1' of one end tooth is 14°, and the chamfering relief angle α2' of the other end tooth is 29°. The angle γ1' is 8°. The rake angle γ of the milling cutter is 8°. The outer diameter φD of the tool holder 1 is 3.175mm, and the outer diameter φd of the milling head 2 is 3.175mm. The core circle diameter φK of the milling head 2 is 1.59mm. The distance e between one edge of the end teeth of the milling cutter and the center is 0.09 mm. The end tooth of the milling cutter is a Closed groove type,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com