Manufacture technology for high-frequency material

A high-frequency material and manufacturing technology technology, applied in the field of high-frequency material manufacturing technology, can solve problems such as roughness, poor yield, and affecting the processing accuracy of printed circuit boards made of Teflon materials, and achieve the effect of property improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solutions of the present invention will be further described below in combination with specific implementation examples.

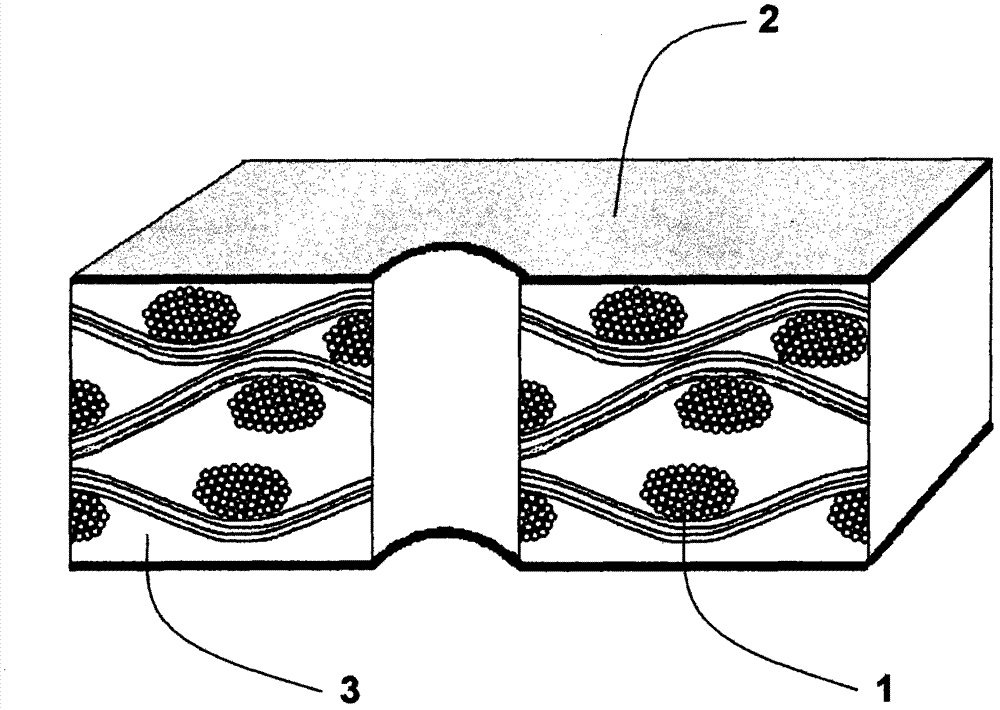

[0019] In order to solve the described problem, a kind of manufacturing technique of high-frequency material is provided, and this material contains copper foil at least (such as figure 1 2 in), Teflon (ie polytetrafluoroethylene) resin (such as figure 1 3 in), glass fiber (such as figure 1 shown in 1) and other substances, copper foil is used as the constituent material of the two surfaces of the material, and the space between the two copper foils is composed of criss-crossed glass fibers and substances including at least polytetrafluoroethylene resin, and the criss-crossed glass The fibers are arranged to enhance the overall strength of the material, and the glass fibers used are treated to reduce the mechanical strength, so that the glass fibers are more convenient for machining during the subsequent manufacturing process.

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com