Production equipment and method of carbon cloth drum

A technology of production equipment and carbon cloth, which is applied in the direction of winding strips, thin material processing, transportation and packaging, etc., can solve the problems of difficult to take off the roll workpiece, and achieve the effect of improving production efficiency and reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical scheme of the present invention is described in detail below in conjunction with accompanying drawing:

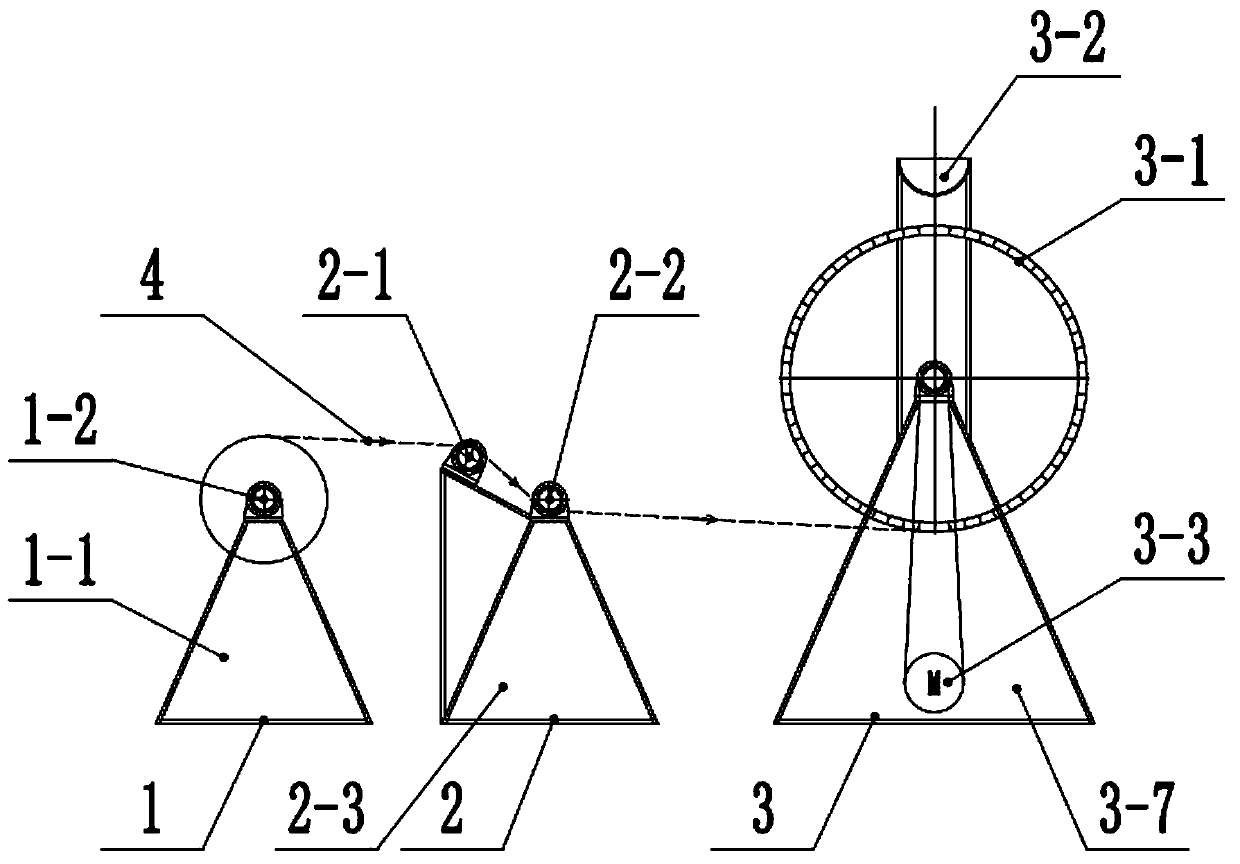

[0018] Such as figure 1 , a kind of carbon cloth reel production equipment, including arranging device 1, tensioning device 2 and winding device 3 arranged in sequence.

[0019] The winding device 3 includes a third frame 3-7, on which a cylindrical wooden mold 3-1 is installed through a rotational connection, and the winding device 3 also includes a motor 3 -3, the motor 3-3 drives the mold 3-1 to rotate through the belt.

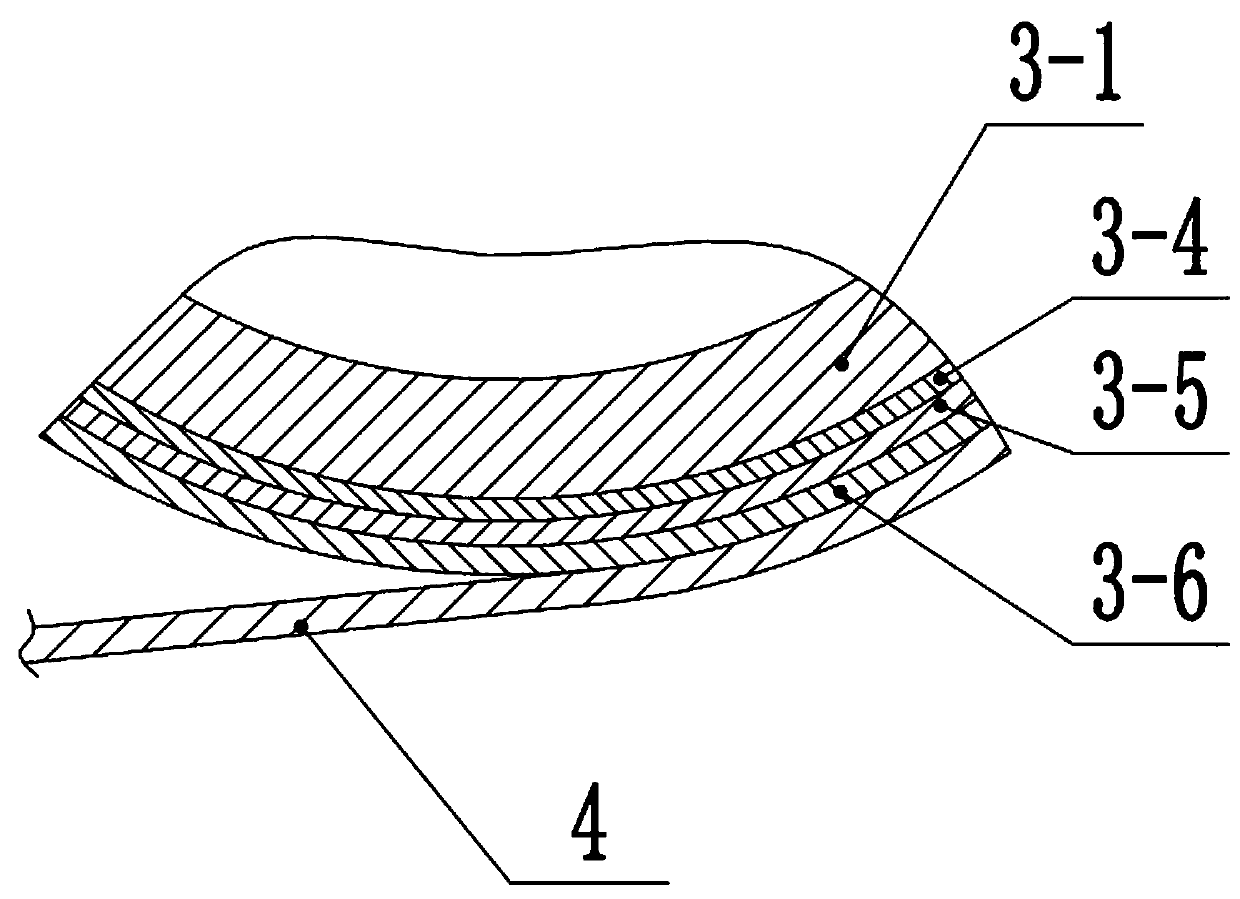

[0020] Described mold 3-1 is used for winding carbon cloth 4, as figure 2 , the outer surface of the mold 3-1 is sequentially coated with a smooth layer, a Teflon film 3-5 and an isolation layer from the inside to the outside; the carbon cloth 4 is wound on the isolation layer. In this embodiment, the smooth layer is heat-shrinkable film 3-4, and the isolation layer is sulfuric acid paper 3-6. The heat-shrinkable film 3-4 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com