Melt-blown fabric and device for processing the melt-blown fabric

A processing device and technology of melt-blown cloth, which are applied to non-woven fabrics, melt-spinning method, feeding solution to spinnerets, etc., can solve the problems of lowering the quality of goods, insufficient connection between additives and melt-blown cloth, and falling off of additives. Achieve scientific and reasonable structure, excellent antistatic properties, safe and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

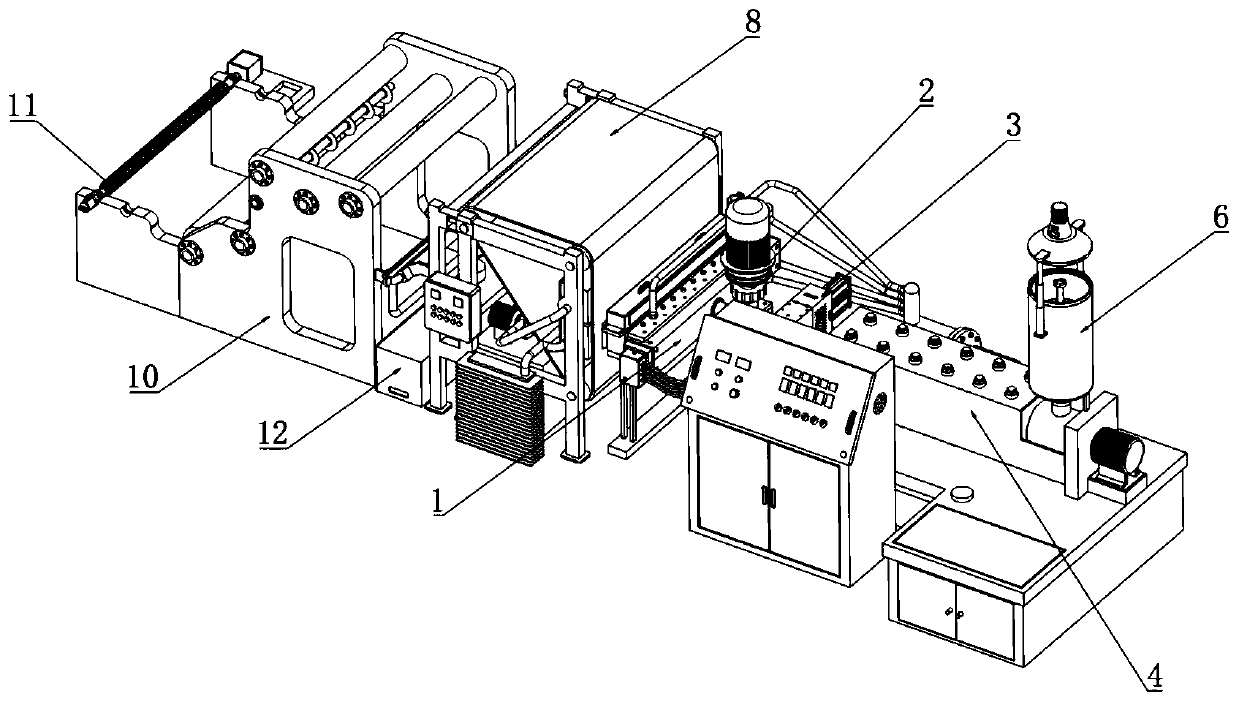

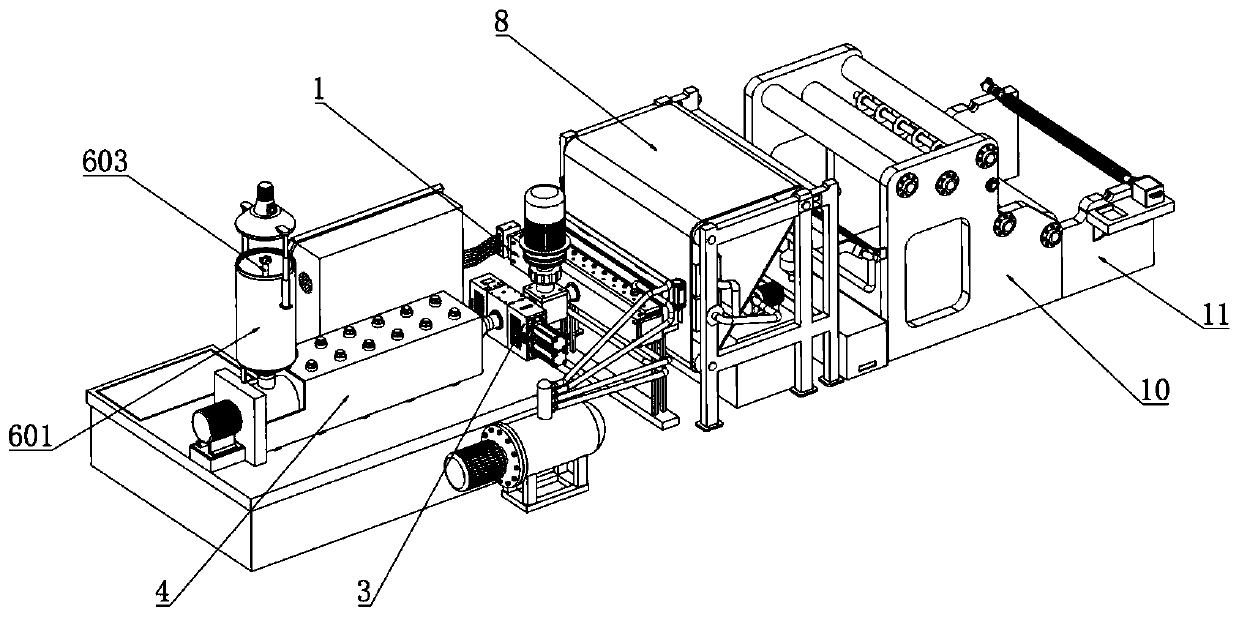

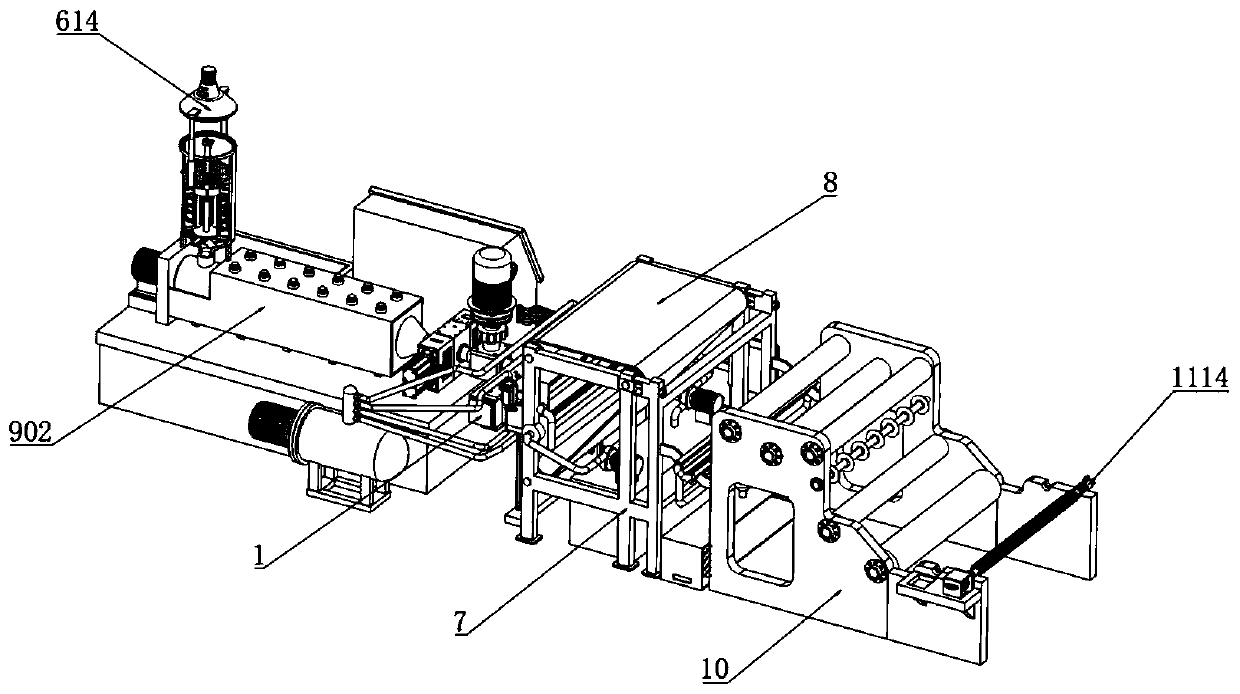

[0075] Example: such as Figure 1-11 As shown, the present invention provides a technical solution, a processing device for melt blown cloth, including a melt blown machine base 1, one end of the melt blown machine base 1 is fixedly connected to a quantitative pump 2, and the input end of the quantitative pump 2 is connected to the commercial power supply. The output end is electrically connected, one end of the quantitative pump 2 is fixedly connected to a melt filter 3, one side of the melt filter 3 is fixedly connected to an extruder 4, and the other end of the melt blown machine base 1 is provided with a solid material adding mechanism 5;

[0076] The solid material adding mechanism 5 includes a support square frame 501, a hopper 502, a mixing chamber 503, a material storage chamber 504, a sealing cover plate 505, a feeding net plate 506, a telescopic box 507, a telescopic spring 508, a sliding plate 509, a feeding Mesh plate 510, transmission bump 511, mounting plate 512,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com